A kind of method for preparing dimer acid diisocyanate

A technology of dimer acid diisocyanate and dimer acid diester, which is applied in the field of preparation of dimer acid diisocyanate, can solve problems such as environmental hazards, limit applications, and weaken the environmental advantages of biochemical raw materials dimer acid, and achieve cost reduction. The effect of low and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

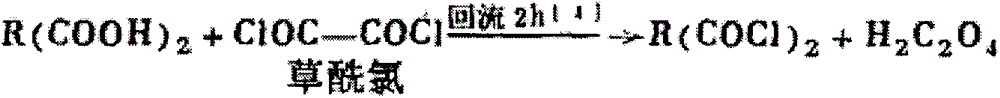

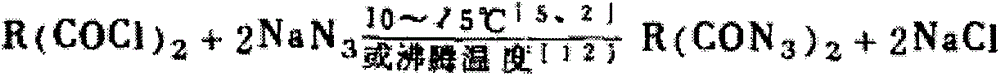

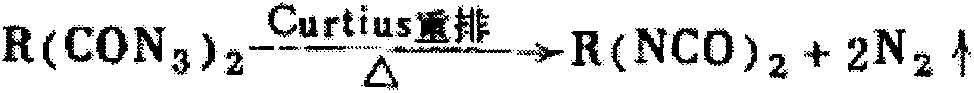

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of dimer acid dihydrazide

[0038] Add 41g of 80% hydrazine hydrate aqueous solution (0.656mol pure hydrazine) into a 500mL four-neck flask, stir at room temperature, add 120g of dimer acid dimethyl ester (0.203mol) and 30g of methanol within 30min, heat up to 90°C and reflux for 90min The system was transparent, and 115 g of light yellow dimer acid dihydrazide was obtained by distillation, with a yield of 95.8%.

[0039] (2) Preparation of dimer acid diacyl azide

[0040] In a 500mL four-neck flask, add 30g of dimer acid dihydrazide prepared in step (1), 25mL of concentrated hydrochloric acid (37% concentration) and 50mL of toluene, and cool the mixture to -5°C-0°C; Temperature -5°C-0°C, slowly add a solution of 10g sodium nitrite and 40mL water dropwise, after the dropwise addition, continue to stir for 30min, separate the organic phase, extract the organic phase twice with 15mL toluene, combine several layers, and then Wash with 30 mL of 5% sodium b...

Embodiment 2

[0044] (1) Preparation of dimer acid dihydrazide:

[0045] Add 82g of 40% hydrazine hydrate solution (0.656mol pure hydrazine) into a 500mL four-neck flask, stir at room temperature, add 120g of dimer acid dimethyl ester (0.203mol) within 30min, heat up to 90°C for reflux reaction for 90min, distill to obtain Light yellow dimer acid dihydrazide 115g, yield 95.0%.

[0046] (2) Preparation of dimer acid diacyl azide and dimer acid diisocyanate

[0047] In a 1000mL four-neck flask, add 100g of dimer acid dihydrazide prepared in step (1), 75mL of concentrated hydrochloric acid (37%) and 150mL of toluene, and cool the mixture to -5°C-0°C; while stirring, maintain the temperature -5°C-0°C, slowly add a solution of 30g sodium nitrite and 45mL water dropwise, after the dropwise addition, continue to stir for 2h, separate the organic phase, extract the organic phase twice with 50mL toluene, combine several phases, and sequentially Wash with 5% sodium bicarbonate and 10% sodium chlori...

Embodiment 3

[0050] Example 3 Preparation of polyurethane elastomer with dimer acid diisocyanate

[0051] Add 30.4 g of hydroxyl-terminated polybutadiene (hydroxyl value 0.73 mmol / g) and 41.2 g of dimer acid diisocyanate in Example 2 into a 250 mL three-necked flask, vacuum dehydrate at 95°C for 2 hours, add 0.12 mL of 10% diisocyanate Dibutyltin tetrahydrofuran laurate solution was vacuumed for 30 minutes, cooled to 60°C, 4.8g of butanediol was added, vacuumized for 20 minutes, and the mixture was poured into a mold preheated to 60°C for 48 hours. The mechanical properties of the prepared polyurethane elastomer were tested, the elongation at room temperature was 1000%, and the tensile strength was 10MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com