Novel synthesis method of N, N'-dicyclohexylcarbo-diimide

A technology of dicyclohexylcarbodiimide and cyclohexylamine, which is applied in the field of N, can solve the problems of large environmental pollution, high production cost, and solvent residue, and achieve the effects of wide application range, cost saving, and no solvent residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

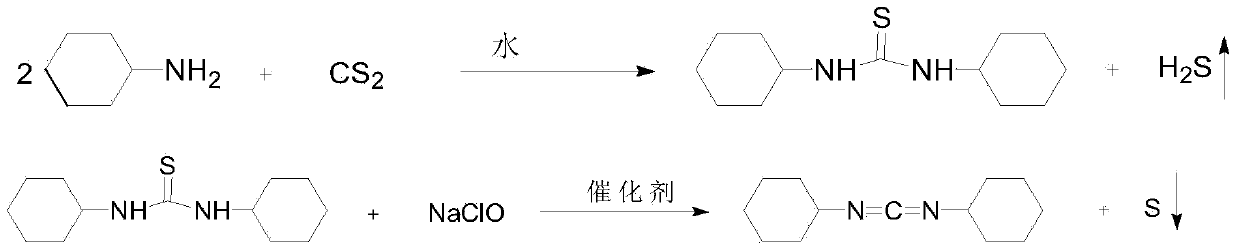

Method used

Image

Examples

Embodiment 1

[0024] Put water and cyclohexylamine with a mass ratio of 3:1 into the autoclave, drop the carbon disulfide which accounts for 0.5 times the amount of cyclohexylamine after cooling down, control the dropping temperature at 34°C, and raise the temperature to 130°C after the carbon disulfide drops, The pressure in the kettle is 0.1MPa, the hydrogen sulfide gas is released and absorbed by liquid alkali to produce a sodium sulfide solution. The solution in the kettle is kept at 130°C for 4 hours and then cooled to 60°C, filtered to obtain N,N'-dicyclohexylthiourea, and then add Mix sodium dodecylbenzenesulfonate with 0.01 times the amount of cyclohexylamine, then add sodium hypochlorite solution accounting for 2 times the mass of cyclohexylamine and 13% available chlorine, heat up to 70°C for 1 hour, and separate the liquid while hot after heat preservation. Add sodium sulfide solution at a temperature of 40°C to the organic phase. The amount of sodium sulfide solution is 3 times t...

Embodiment 2

[0026] Put water and cyclohexylamine with a mass ratio of 4:1 into the high-pressure reactor, drop carbon disulfide 0.4 times the amount of cyclohexylamine after cooling down, control the dropping temperature at 0°C, and raise the temperature to 100°C after the addition of carbon disulfide. The pressure in the kettle is 0.4MPa, the hydrogen sulfide gas is released and absorbed by liquid alkali to produce a sodium sulfide solution. The solution in the kettle is kept at 100°C for 6 hours and then cooled to 25°C, filtered to obtain N,N'-dicyclohexylthiourea, and then add Mix tetrabutylammonium chloride with 0.5 times the amount of cyclohexylamine, then add sodium hypochlorite solution accounting for 8 times the mass of cyclohexylamine and 8% available chlorine, heat up to 40°C for 3h, separate liquid while hot after heat preservation, and transfer to organic Add sodium sulfide solution at a temperature of 60°C to the phase, the amount of sodium sulfide solution is 5 times the mass...

Embodiment 3

[0028] Put water and cyclohexylamine with a mass ratio of 3.5:1 into the autoclave, drop the carbon disulfide 0.6 times the amount of cyclohexylamine after cooling down, control the dropping temperature at 20°C, and raise the temperature to 160°C after the drop of carbon disulfide is completed. The pressure in the kettle is 0.6MPa, the hydrogen sulfide gas is released and absorbed by liquid alkali to produce a sodium sulfide solution. The solution in the kettle is kept at 160°C for 2 hours and then cooled to 45°C, filtered to obtain N,N'-dicyclohexylthiourea, and then add Mix tetrabutylammonium bisulfate with 0.2 times the amount of cyclohexylamine, then add a sodium hypochlorite solution that accounts for 10 times the mass of cyclohexylamine and has 10% available chlorine, heat up to 60°C and keep it for 2 hours. Add a sodium sulfide solution at a temperature of 80°C to the phase, the amount of the sodium sulfide solution is 0.01 times the mass of cyclohexylamine added, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com