Continuously blended liquefied polymer thickener for fracturing construction

A technology of polymers and thickeners, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of fisheye and agglomeration, slow hydration speed, uneven dispersion, etc. clumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

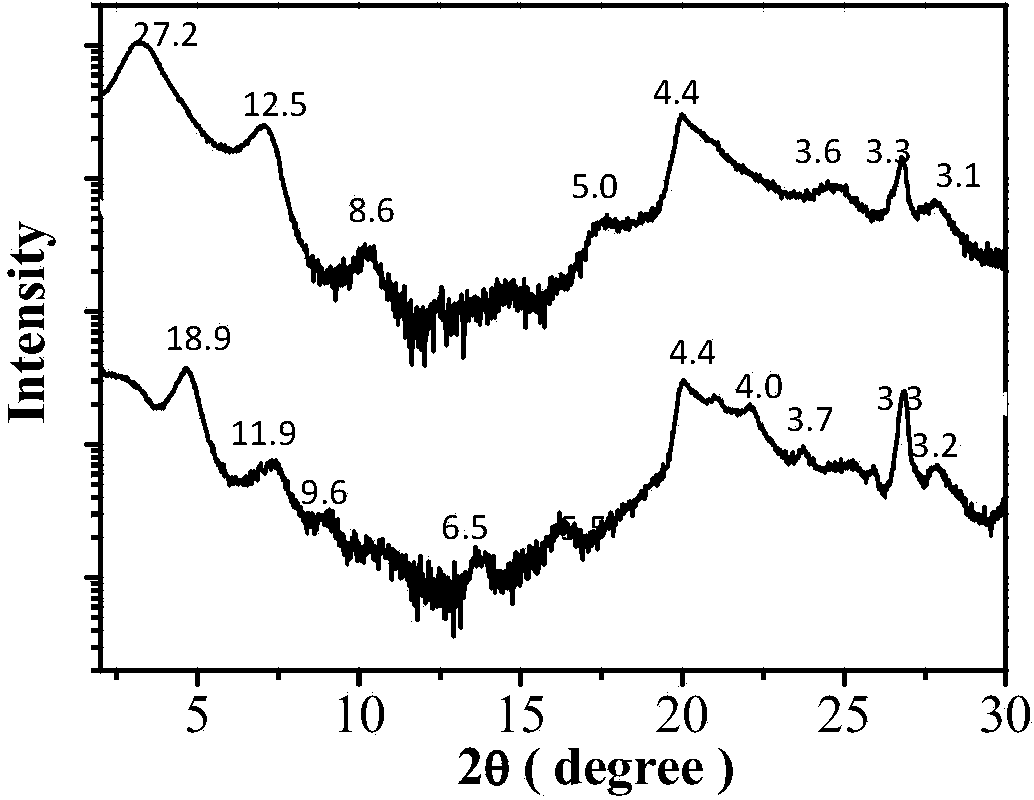

[0034] Embodiment 1: the synthesis of organoclay

[0035] 1. Synthesis of organoclay sample A1

[0036] Add 100 g of Na-montmorillonite to 500 ml of deionized water, and stir vigorously for 10 minutes. Add 70 grams of dioctadecyldimethylammonium chloride as a treatment agent to the resulting suspension, heat the mixture to 80-90° C., and continue to stir for 12 hours. The precipitate generated by the reaction was filtered, and the filtrate was washed 3 times with 100 ml of deionized water. The filtrate was dried in a vacuum oven (90° C.) for 24 hours, and pulverized to obtain organoclay A1 whose modified component was dioctadecyldimethylammonium.

[0037] 2. Synthesis of organoclay sample A2

[0038] Add 100 g of Na-montmorillonite to 500 ml of deionized water, and stir vigorously for 10 minutes. Add 40 grams of cetyltrimethylammonium bromide as a treatment agent to the resulting suspension, heat the mixture to 80-90° C., and continue stirring for 12 hours. The precipitat...

Embodiment 2

[0039] Embodiment 2: formula test

[0040] Preparation of Reference Sample 1

[0041] Add 15.2 grams of liquid paraffin (produced by Tianjin Chemical Plant), 0.18 grams of methyl alcohol, and 0.55 grams of surfactant OP-10 in 100 milliliters of jars, stir vigorously for 10 minutes (1000 rev / min), continue to stir, The mixed liquid was slowly added with 10.5 grams of hydroxypropyl guar gum powder. After the addition was complete, the stirring was continued for 30 minutes, and the stirring was stopped to obtain Comparative Sample 1. Pour the sample into a graduated cylinder, observe the phenomenon, and record the time required for delamination to appear 5% clear liquid and 20% delamination. The results are shown in Table 1.

[0042] Preparation of reference sample 2

[0043] Add 15.2 grams of liquid paraffin (produced by Tianjin Chemical Plant), 0.41 grams of organoclay A1, and 0.18 grams of methanol in a 100ml wide-mouth bottle, stir vigorously for 10 minutes (1000 rpm), co...

Embodiment 3

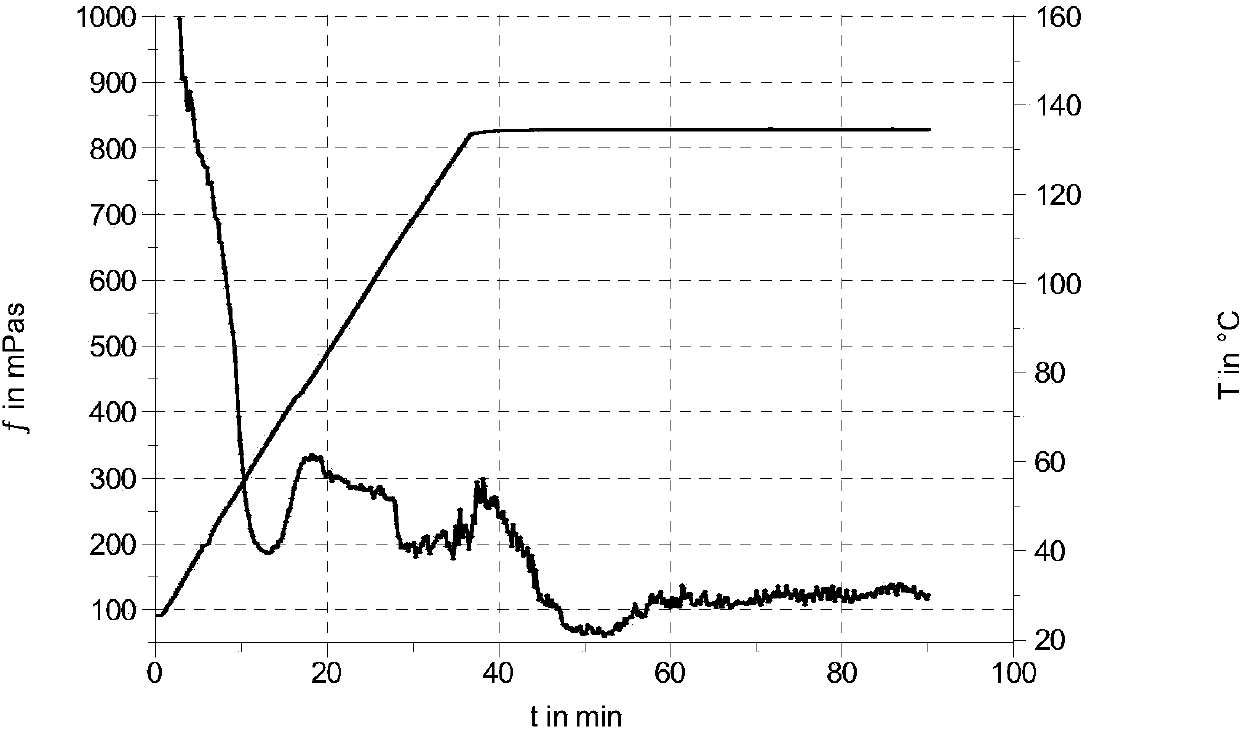

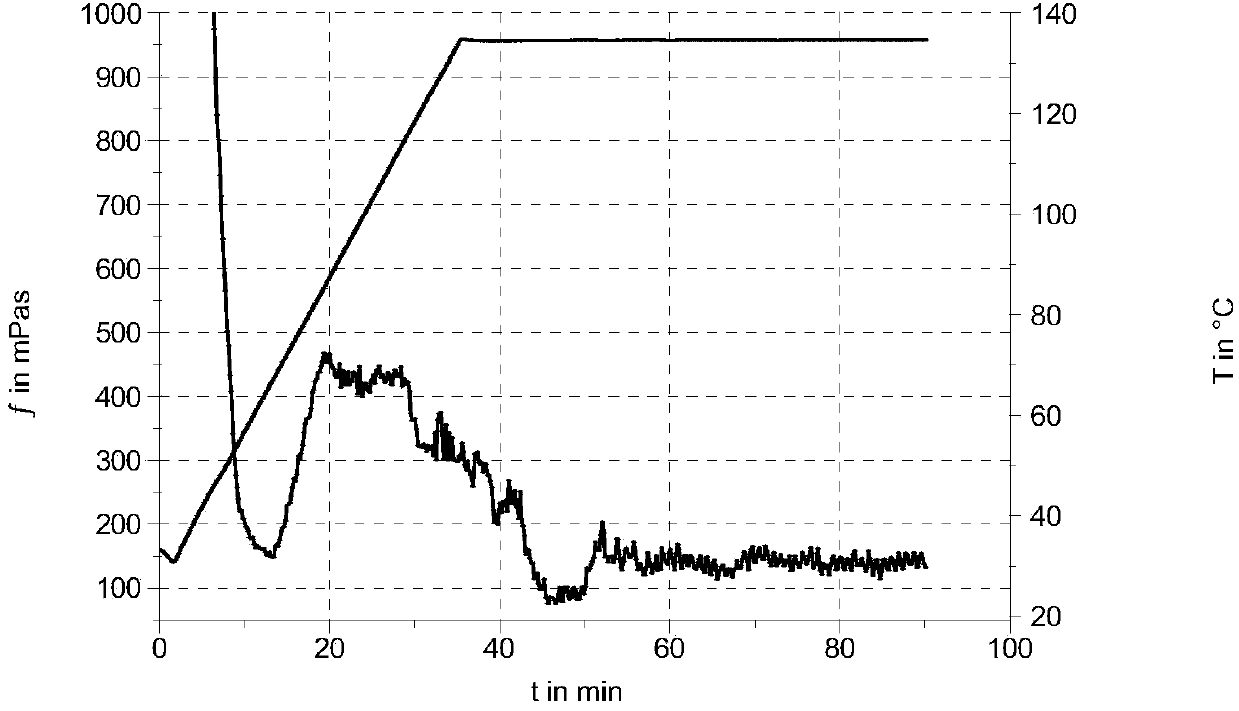

[0048] Embodiment 3: the suspension test of polymer in liquid paraffin

[0049] Preparation of sample 5

[0050] Add 15.2 grams of liquid paraffin (produced by Tianjin Chemical Plant), 0.41g of organoclay A2, 0.18 grams of methyl alcohol, 0.55 grams of surfactant OP-10 in a 100ml wide-mouth bottle, stir vigorously for 10 minutes (1000 rpm ), continue to stir, slowly add 10.5 grams of hydroxypropyl guar gum powder in the mixed liquid. After the addition was complete, the stirring was continued for 30 minutes, and the stirring was stopped to obtain sample 5. Pour the sample into a graduated cylinder, observe the phenomenon, and record the time required for delamination to appear 5% clear liquid and 20% delamination. The results are shown in Table 1.

[0051] Preparation of sample 6

[0052] Add 15.2g of liquid paraffin (produced by Tianjin Chemical Plant), 0.41 gram of organoclay A1, 0.18 gram of methyl alcohol, 0.55 gram of surfactant OP-10 in a 100ml wide-mouth bottle, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com