Refrigerant oil composition

A technology for refrigerating machine oil and composition, applied in the directions of lubricating composition, petroleum industry, etc., can solve the problems of insufficient low temperature performance, lack of naphthenic oil resources, insufficient scratch resistance, etc., and achieves low friction coefficient, good heat Chemical stability, improved scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

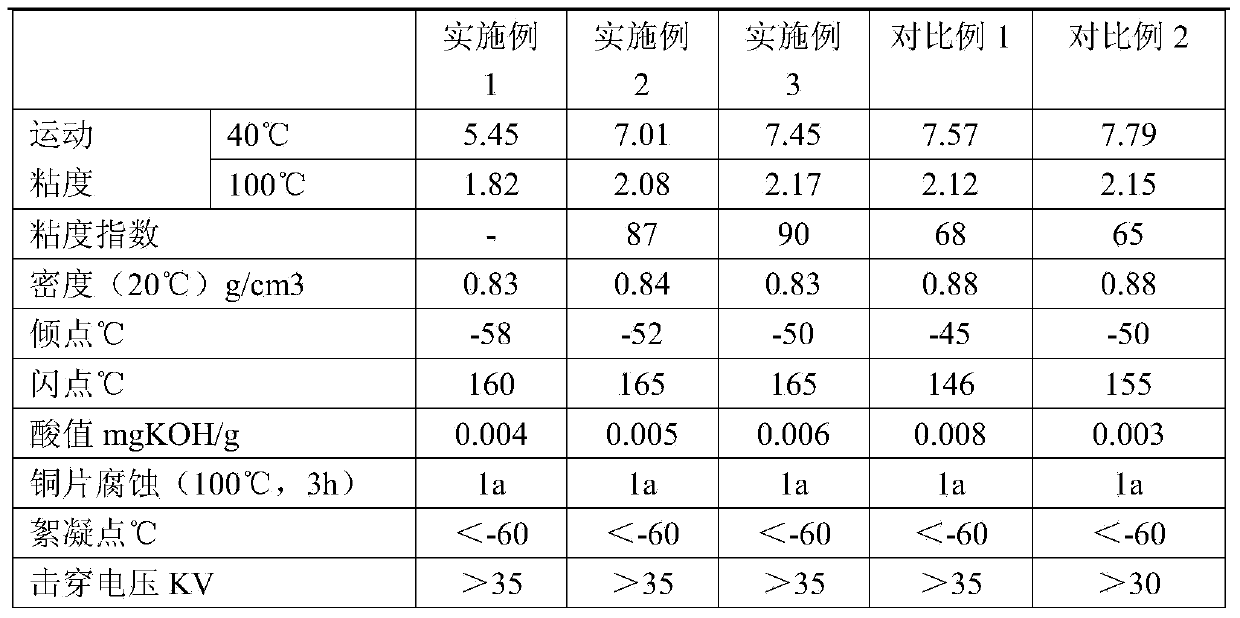

[0038] This example is used to illustrate the refrigerating machine oil composition and its preparation method provided by the present invention.

[0039] Using hydrogenated paraffin base oil with a distillation range of 300-350°C and alkylbenzene with a distillation range of 270-330°C as the base oil, adjust the ratio of paraffin base oil to alkylbenzene to obtain 3.0-5.5mm 2 / s viscosity. Add 2% of dibutylphenyl phenyl phosphate additives, 0.5% of Additin 7110 phenol antioxidant, 0.1% of methyl oleate, 0.01% of 2-mercaptobenzothiadiazole, and 30PPM of silicon defoamer to prepare the described Refrigeration oil, its physical and chemical properties are shown in Table 1.

Embodiment 2

[0041] Using hydrogenated paraffin base oil with a distillation range of 300-350°C and alkylbenzene with a distillation range of 270-330°C as the base oil, adjust the ratio of paraffin base oil to alkylbenzene to obtain 5.0-7.0mm 2 / s viscosity. Add 3% triphenyl phosphite, 0.25% Irganox 135 phenol antioxidant, 0.25% butyl, octyl diphenylamine, 0.05% butyl oleate, 0.01 N, N-dialkylaminomethylene benzotriazole % deployed into refrigeration oil, its physical and chemical properties are shown in Table 1.

Embodiment 3

[0043] Using hydrogenated paraffin base oil with a distillation range of 300-350°C and alkylbenzene with a distillation range of 270-330°C as the base oil, adjust the ratio of paraffin base oil and alkylbenzene to obtain 6.0-7.5mm 2 / s viscosity. Add 1% tricresyl phosphate, 1% triphenyl phosphate, 0.4% Irganox 135 phenolic antioxidant, 0.1% Irganox L57 amine antioxidant, 0.01% 2-mercaptobenzothiadiazole, silicon antifoam 10PPM is formulated into refrigeration oil, and its physical and chemical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com