Piezoelectric driven and detected miniature hemispherical resonant gyroscope and manufacturing method thereof

A technology of hemispherical resonant gyroscope and piezoelectric drive, applied in gyroscope/steering sensing equipment, gyro effect for speed measurement, instrument and other directions, can solve problems such as gyroscope influence, reduce processing requirements and energy consumption requirements, and improve accuracy performance and the effect of avoiding the influence of parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

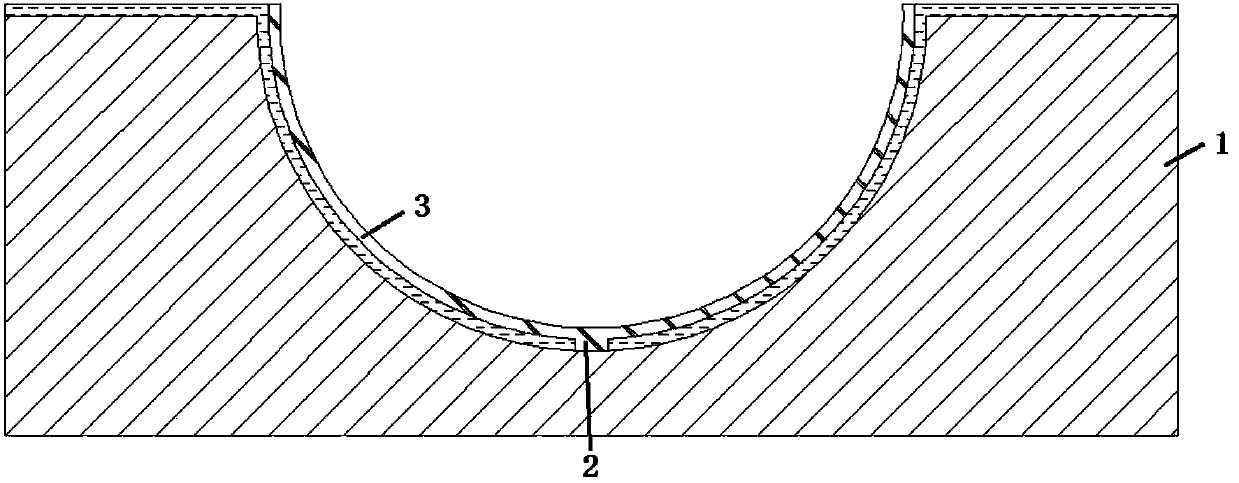

[0036] As shown in Figure 2(a) and Figure 2(b), the present embodiment provides a piezoelectrically driven and detected miniature hemispherical resonant gyroscope, including:

[0037] a single crystal silicon substrate 1;

[0038] a central fixed support column 2;

[0039] A miniature hemispherical harmonic oscillator 3;

[0040] a common electrode 4;

[0041] Eight thin-film piezoelectric bodies 5;

[0042] Eight evenly distributed signal electrodes 6;

[0043] Among them, the single crystal silicon substrate 1 and the micro-hemispherical resonator 3 are connected through the central fixed support column 2; the common electrode 4 has the same shape as the micro-hemispherical resonator 3, and is located between the micro-hemispherical resonator 3 and the thin-film piezoelectric body 5; The thin-film piezoelectric body 5 has the same shape as the signal electrode 6 and is located between the common electrode 4 and the signal electrode 6 .

[0044] In this embodiment, the m...

Embodiment 2

[0051] Such as Figure 1(a)-Figure 1(i) As shown, the present embodiment provides a preparation method of the piezoelectrically driven and detected miniature hemispherical resonant gyroscope, comprising the following steps:

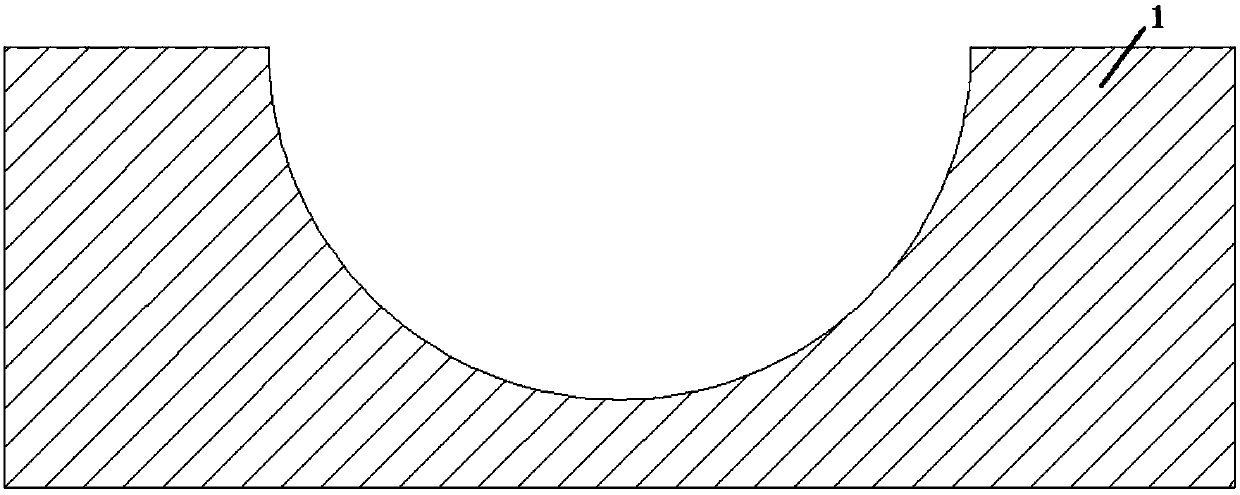

[0052]The first step, as shown in Fig. 1(a), is to clean the single crystal silicon substrate 1, apply glue on the single crystal silicon substrate 1, perform photolithography, development, sputtering mask layer, glue removal, and isotropic Etching and removing the mask layer to obtain a hemispherical groove with a radius of 300-700 μm on the single crystal silicon substrate 1;

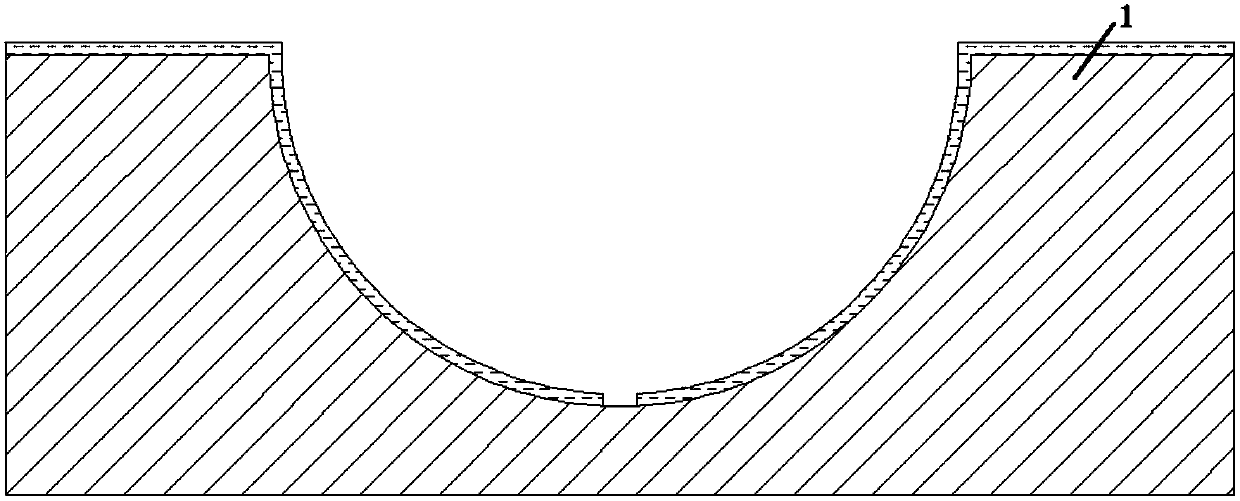

[0053] In the second step, as shown in Figure 1(b), on the basis of the first step, the thermal oxidation method is used to grow the silicon dioxide layer, glue coating, photolithography, development, and partial etching of the silicon dioxide layer to obtain a radius SiO2 sacrificial layer for 15-40 μm circular grooves;

[0054] The third step, as shown in Figure 1(c), deposits...

Embodiment 3

[0063] Basically the same as embodiment 1 and embodiment 2, the difference is:

[0064] The gyroscope prepared in this embodiment: the material of the central fixed support column 2 and the micro-hemispherical resonator 3 is doped polysilicon or doped diamond, which can be used as the micro-hemispherical resonator 3 and the common electrode 4 at the same time, without Make additional common electrode 4;

[0065] Therefore, the third step in the preparation method of this embodiment: deposit doped polysilicon or doped diamond on the basis of the second step; remove the fourth step in the preparation method described in Example 2, and directly proceed from the fifth step to the first step nine steps. Other operations are the same as in Example 2.

[0066] The gyroscope in the present invention is manufactured by combining MEMS bulk silicon processing technology and surface silicon processing technology, which is a novel processing technology.

[0067] The present invention ut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com