Method for determining content of copper in copper electrolyte

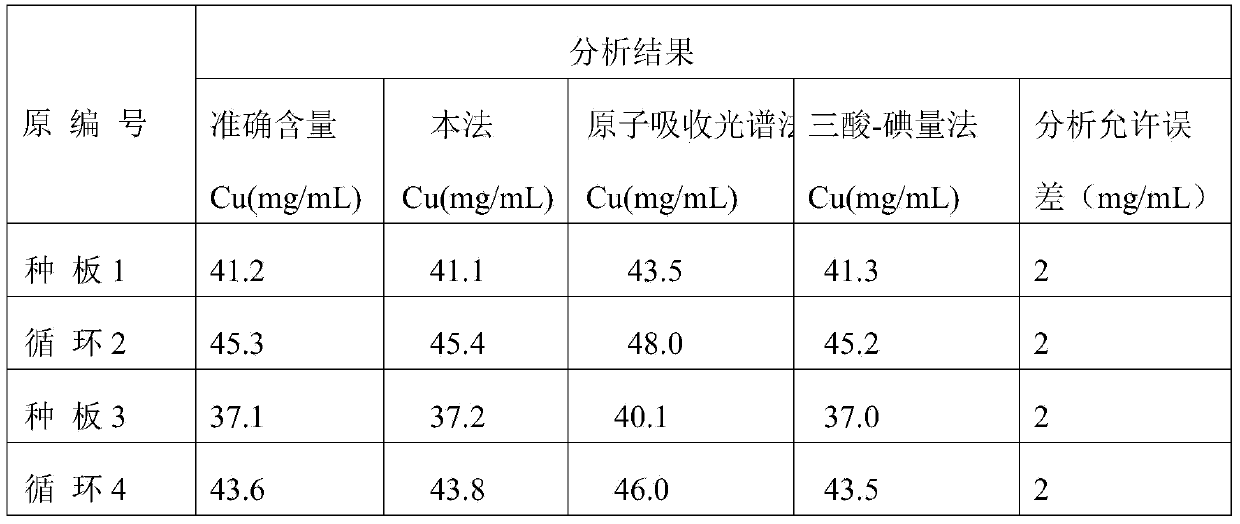

A technology of copper electrolyte and determination method, which is applied in the direction of chemical analysis by titration method, can solve the problems of long sample processing time, large deviation of results, high salt content, etc., and achieve accurate and reliable analysis results, short measurement time and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The assay method of copper content in a kind of copper electrolyte of the present embodiment comprises the following steps:

[0019] 1) Take 2mL of copper electrolyte in a 300mL beaker;

[0020] 2) Neutralize with 2mL of ammonia water until iron is completely precipitated;

[0021] 3) Add 1g of ammonium bifluoride to cover the iron, add 2g of potassium iodide, and titrate with a sodium thiosulfate standard solution with a concentration of 0.003126g / mL, and calculate the copper content w according to the concentration and consumption volume of the sodium thiosulfate standard solution Cu .

Embodiment 2

[0023] The assay method of copper content in a kind of copper electrolyte of the present embodiment comprises the following steps:

[0024] 1) Take 5mL of copper electrolyte in a 300mL beaker;

[0025] 2) Neutralize with 5mL of ammonia water until the iron is completely precipitated;

[0026] 3) Add 2g of ammonium bifluoride to cover iron, add 3g of potassium iodide, and titrate with a sodium thiosulfate standard solution with a concentration of 0.003126g / mL, and calculate the copper content w according to the concentration and consumption volume of the sodium thiosulfate standard solution Cu .

Embodiment 3

[0028] The assay method of copper content in a kind of copper electrolyte of the present embodiment comprises the following steps:

[0029] 1) Take 3mL of copper electrolyte in a 300mL beaker;

[0030] 2) Neutralize with 3mL of ammonia water until the iron is completely precipitated;

[0031] 3) add 1.5g ammonium bifluoride to cover iron again, add 2.5g potassium iodide, be that the sodium thiosulfate standard solution of 0.003126g / mL is titrated with concentration, calculate copper content w according to the concentration and consumption volume of sodium thiosulfate standard solution Cu .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com