Multi-focus light spot energy homogenizing Fresnel lens

A Fresnel lens, energy uniform technology, applied in the lens, optics, photovoltaic power generation and other directions, can solve the problems of increasing the internal consumption of solar cells, reducing the output capacity of solar cells, uneven irradiation of solar cells, etc. Improve quality, precision and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

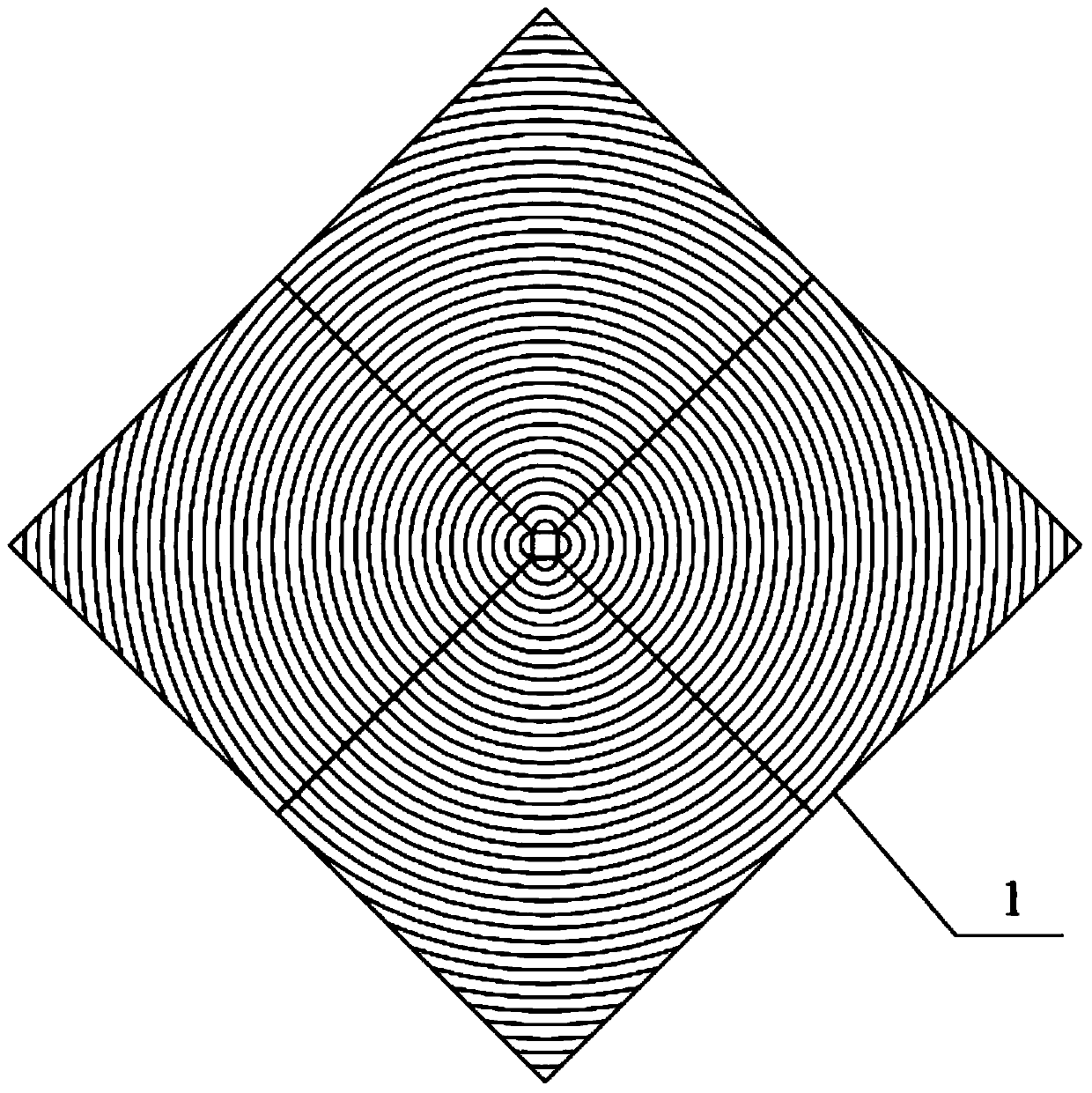

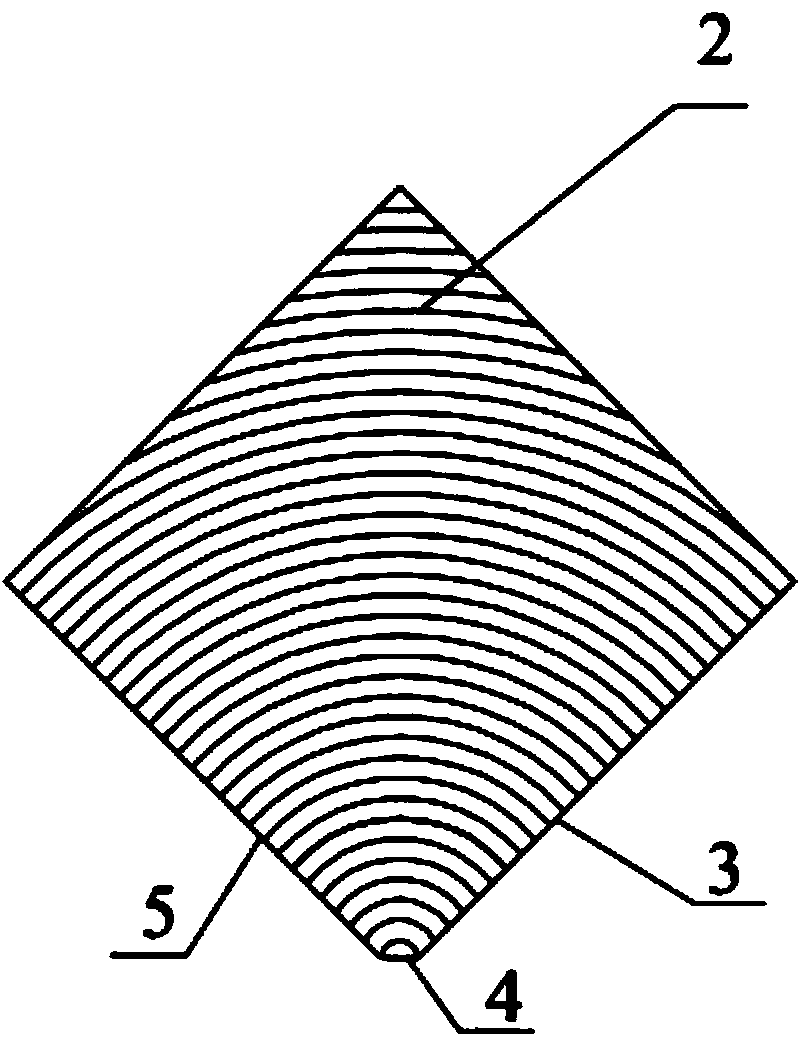

[0032] The schematic diagram of the Fresnel lens 1 for multi-focus spot energy homogenization described in the present embodiment is as follows figure 1 shown. It is composed of four identical unit Fresnel lenses 2 (eg figure 2 shown) are spliced together; the lens surface of the unit Fresnel lens 2 is engraved with concentric circular arcs from small to large, and the lens surface is pentagonal (shape is a square with missing corners), including the first side 3 , the second side 4 and the third side 5; the two end points of the second side 4 are connected with the first side 3 and the third side 5 respectively; the smallest concentric arc of the lens surface is a semicircle, and the second side The side 4 coincides completely with the chord of the semicircle; the first side 3 and the third side 5 are symmetrical about a straight line L which is perpendicular to the second side 4 and passes through the center of the concentric arc of the lens surface. The multi-focus spo...

Embodiment 2

[0039] The unit Fresnel lens 2 in the multi-focus spot energy homogenization Fresnel lens 1 described in the present embodiment is obtained by cutting from the semicircular Fresnel lens according to the following method:

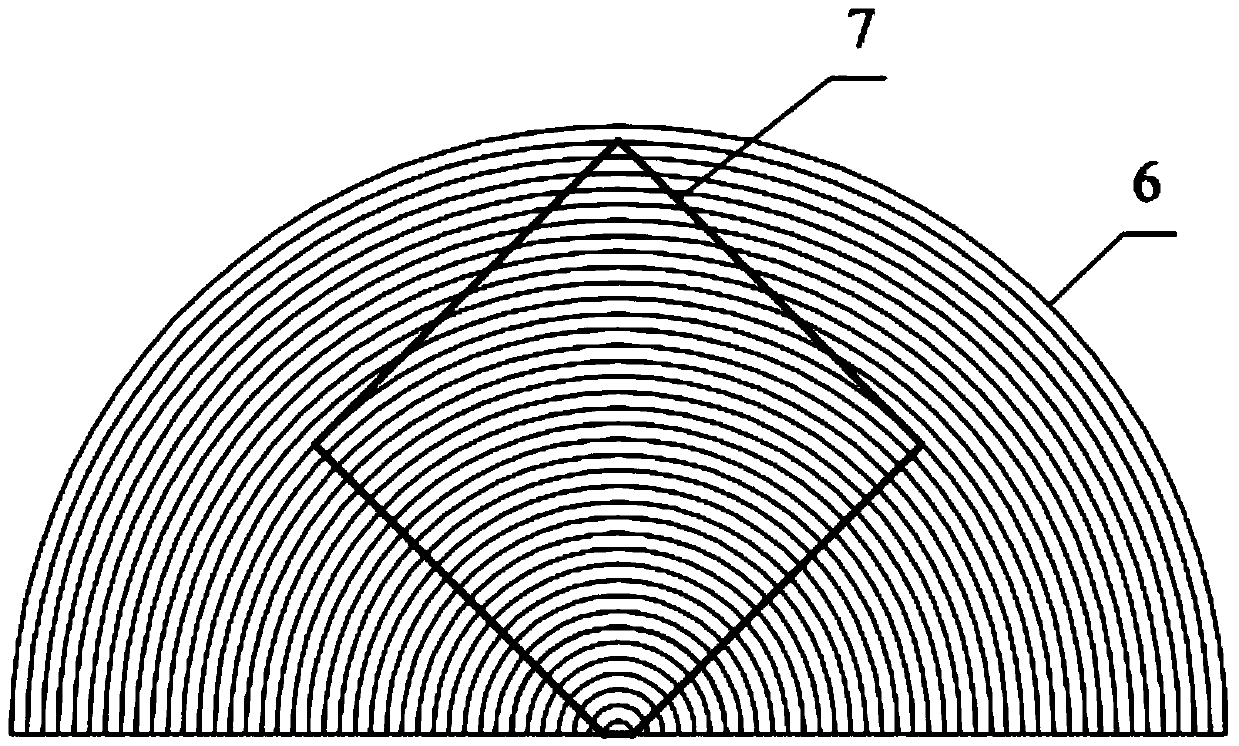

[0040] (1) circular Fresnel lens (diameter is 300mm, and the diameter of its smallest concentric semicircle is 5mm) is equally divided into two semicircular Fresnel lenses 6 along the diameter of concentric circle;

[0041] (2) cut on step (1) gained semicircle Fresnel lens 6 and obtain a unit Fresnel lens 2, the side length of described unit Fresnel lens 2 and unit Fresnel lens 2 maximum concentric arcs The length ratio of the radius is 1:3; the lens surface of the unit Fresnel lens 2 is pentagonal, and its shape is a square with missing corners, including the first side 3, the second side 4 and the third side 5; Two endpoints of the second side 4 are connected with the first side 3 and the third side 5 respectively, the second side 4 is on the same straigh...

Embodiment 3

[0045] The unit Fresnel lens 2 in the multi-focus spot energy homogenization Fresnel lens 1 described in the present embodiment is obtained by cutting from the semicircular Fresnel lens according to the following method, specifically comprising the following steps:

[0046] (1) circular Fresnel lens (diameter is 300mm, and the diameter of its smallest concentric semicircle is 5mm) is equally divided into two semicircular Fresnel lenses 6 along the diameter of concentric circle;

[0047] (2) cut on step (1) gained semicircle Fresnel lens 6 and obtain a unit Fresnel lens 2, the side length of described unit Fresnel lens 2 and unit Fresnel lens 2 maximum concentric arcs The length ratio of the radius is 1:3; the lens surface of the unit Fresnel lens 2 is pentagonal, and its shape is a square with missing corners, including the first side 3, the second side 4 and the third side 5; Two endpoints of the second side 4 are connected with the first side 3 and the third side 5 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com