Control method for immersed photoetching immersion head pose regulating mechanism

A control method and a technology of an adjustment mechanism, which are applied in the direction of use feedback control, microlithography exposure equipment, photolithography exposure device, etc., can solve problems affecting the immersion head posture, immersion head posture does not meet the work requirements, immersion head Problems such as not meeting the work requirements to achieve the effect of ensuring portability, scalability, stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

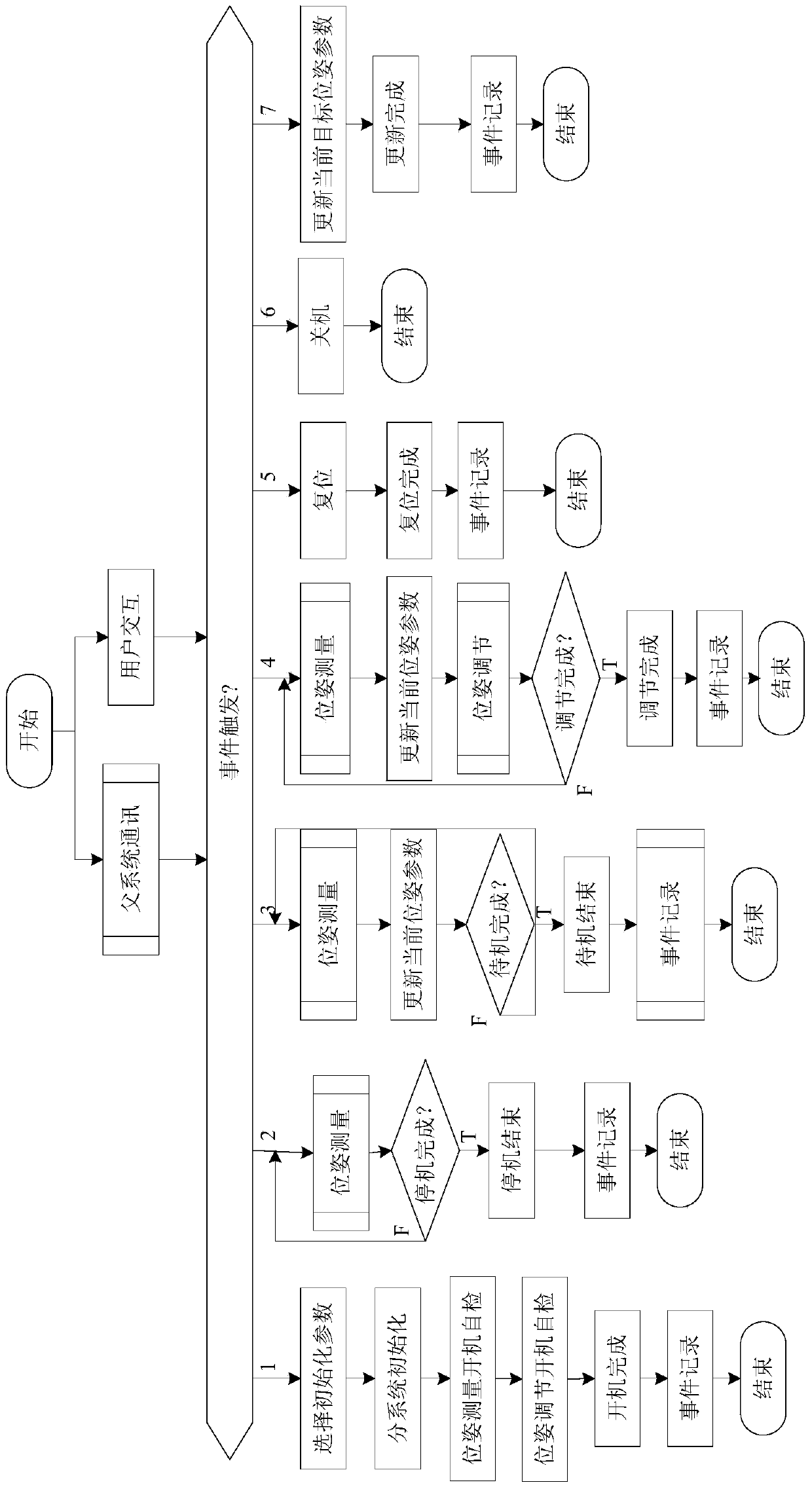

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

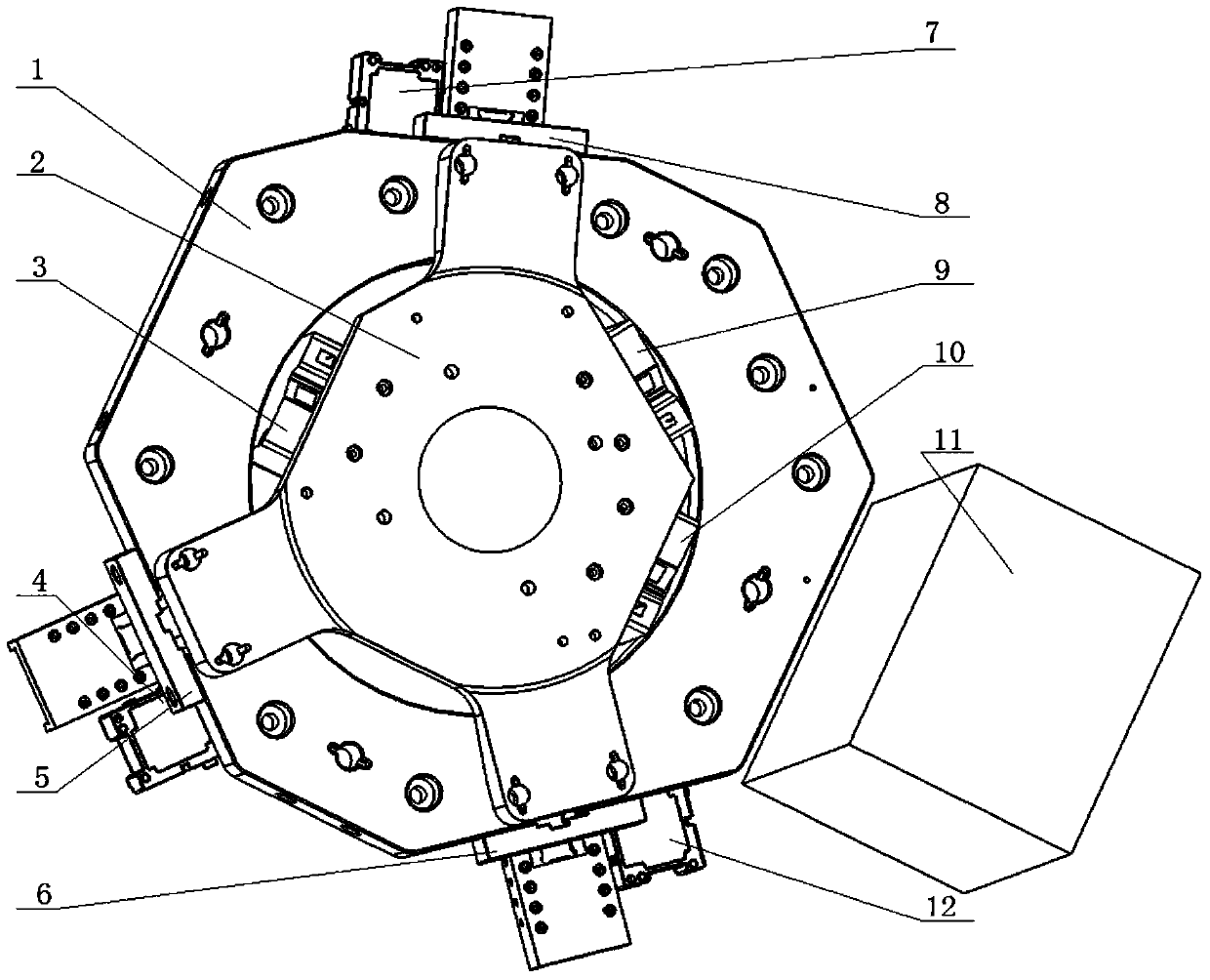

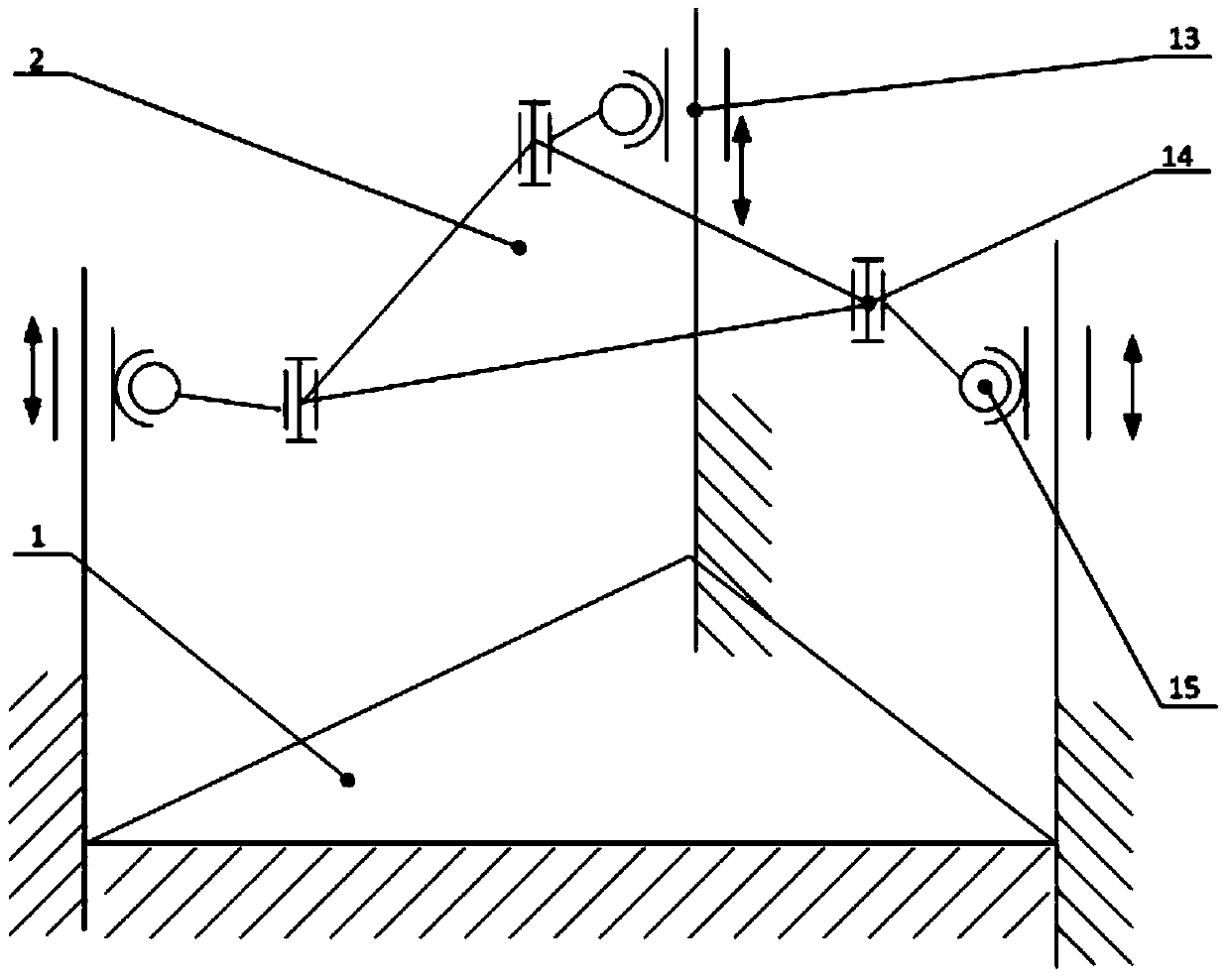

[0028] like figure 1 As shown, it is a three-dimensional model diagram of the immersion head posture adjustment mechanism of the immersion lithography machine, figure 2 Schematic diagram of the structure of the organization.

[0029] Three voice coil linear motors 4, 7, 12 are fixed on the same distribution circle on the side of fixed platform 1, the angle between motor 4 and motor 7 is 120°, the angle between motor 7 and motor 12 is 160°, the three motors It is the power source of the parallel mechanism; three grating rulers 5, 6, and 8 are respectively fixedly installed within the stroke range above the three linear motors, and are used for real-time feedback of motor position information; three laser displacement sensors 3, 9, and 10 are fixedly installed On the lower surface of the motion platform 2, distributed on the same distribution circle, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com