Three-level IGBT power cabinet based on heat pipe radiator

A heat pipe radiator and three-level technology, which is applied to output power conversion devices, electrical components, cooling/ventilation/heating transformation, etc., can solve problems such as complex control algorithms, complex structural layout of switching devices, and potential imbalance. It achieves the effects of high modularization, helpful maintenance and debugging work, and less equipment dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

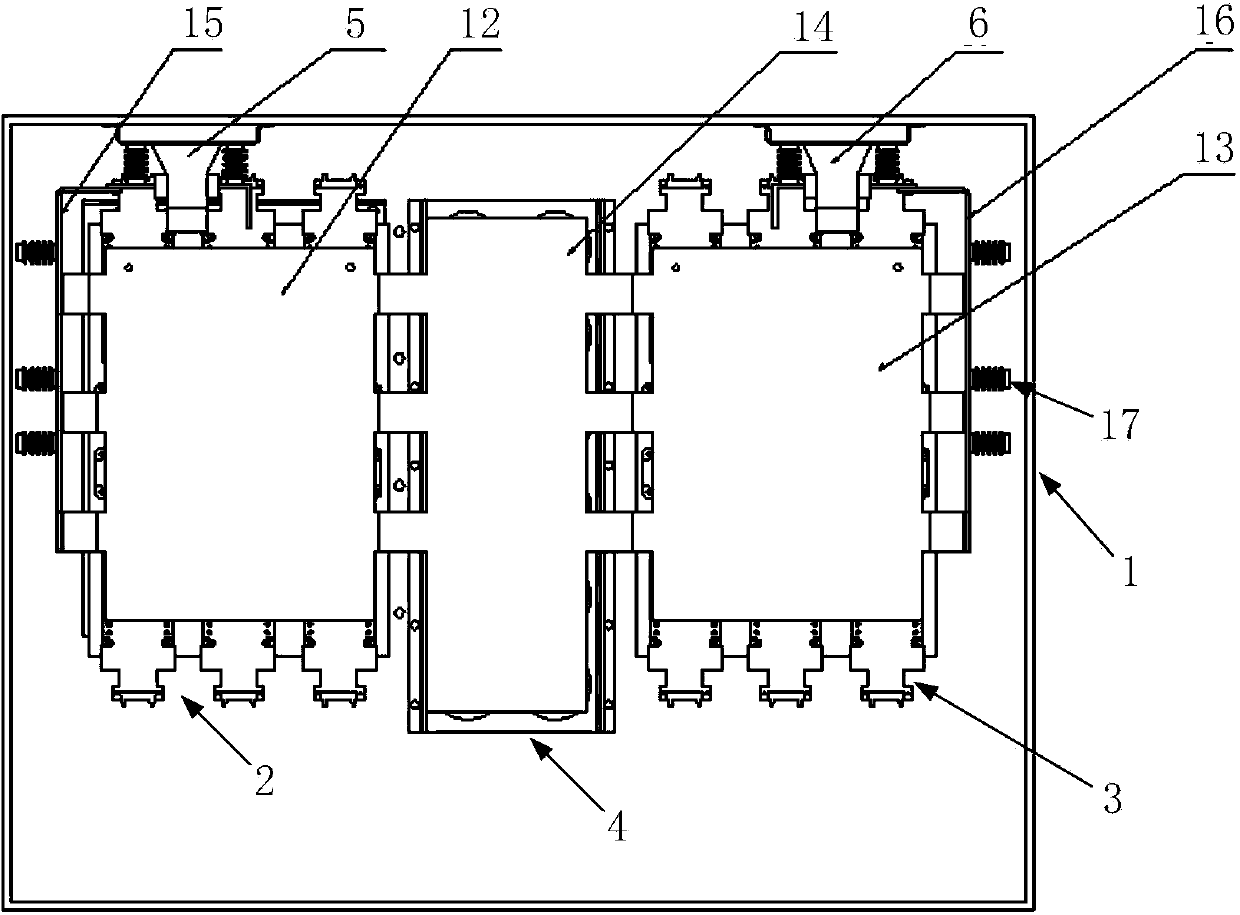

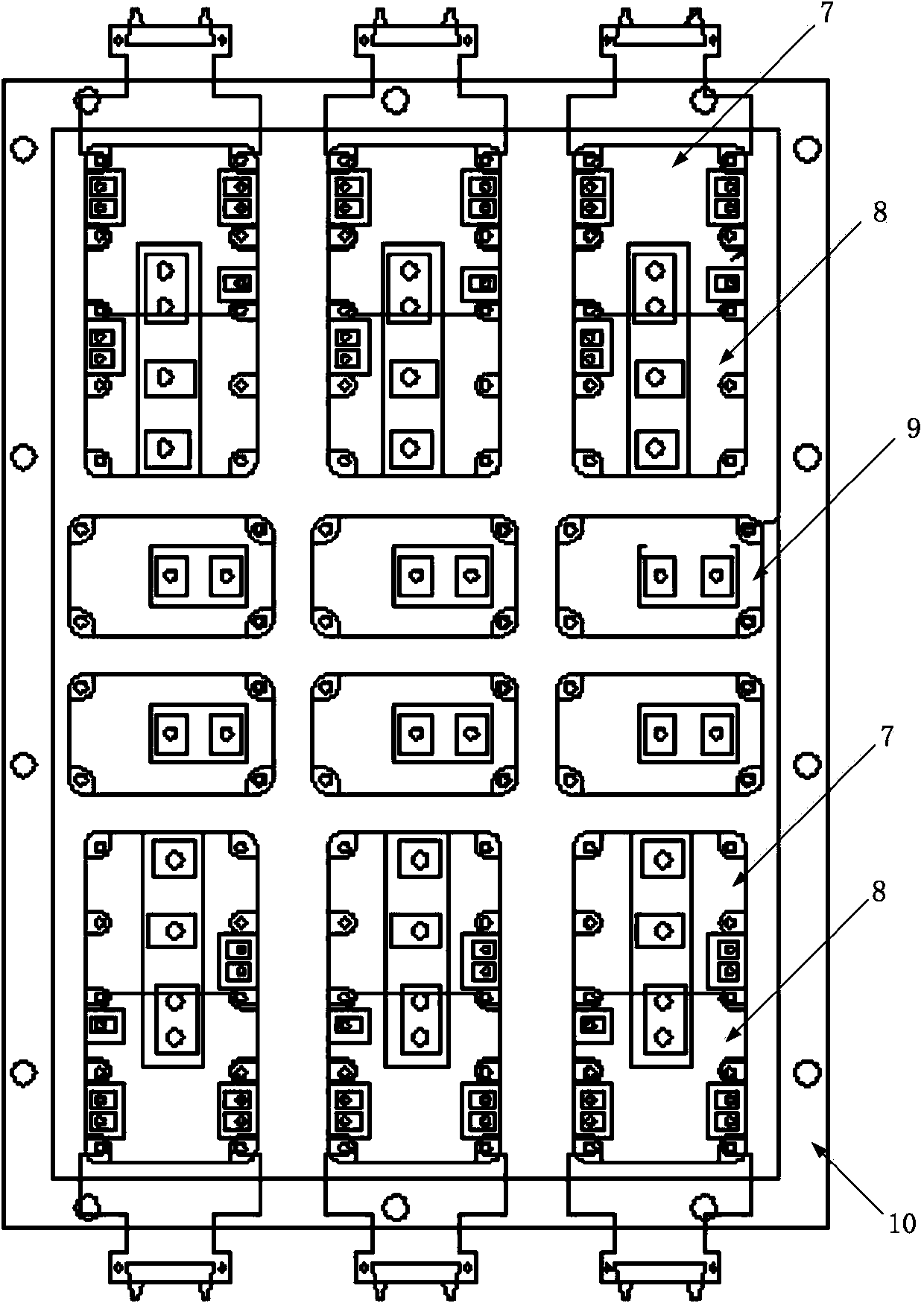

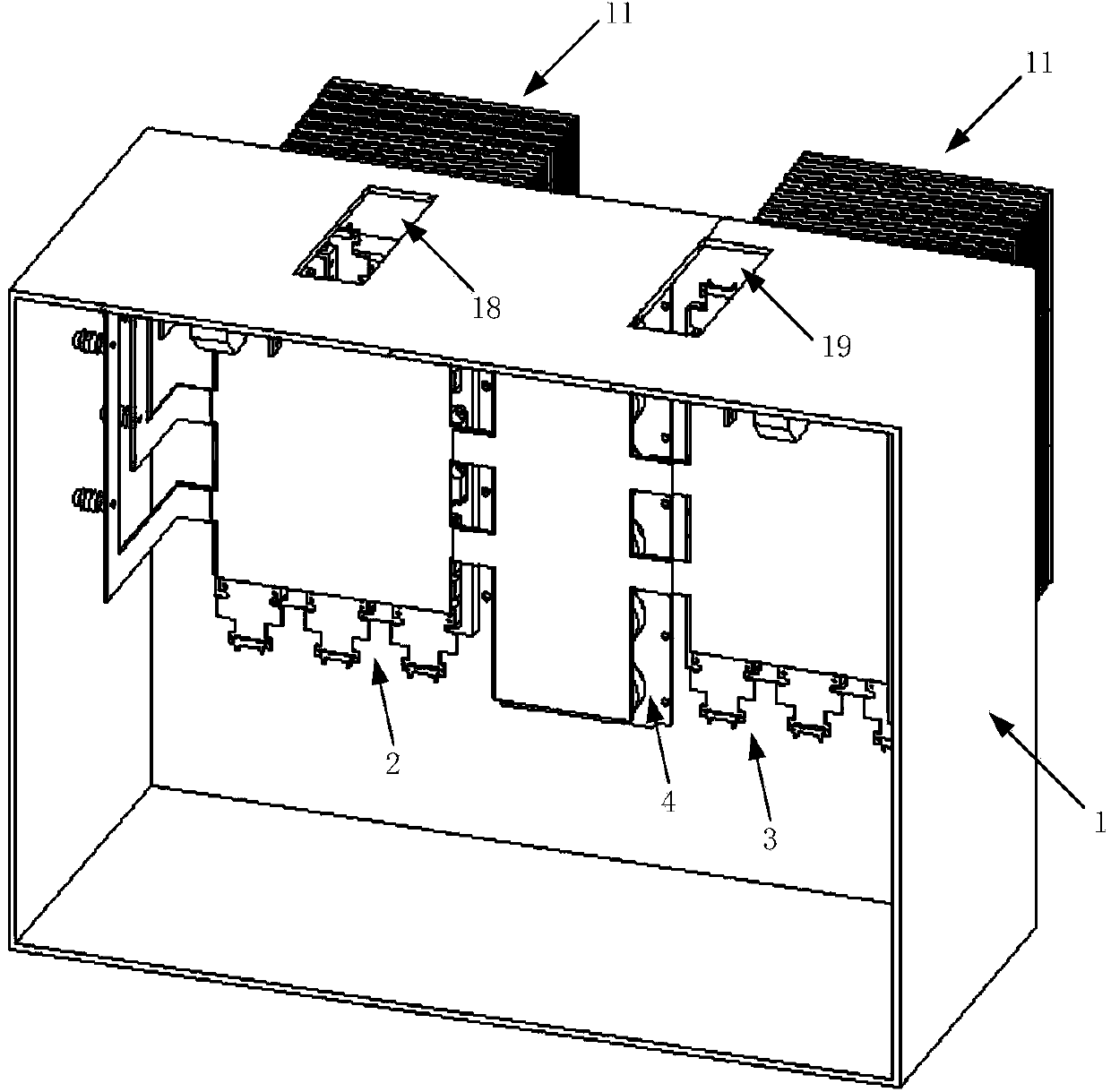

[0026] The present invention is a three-level IGBT power cabinet based on a heat pipe radiator, comprising a cabinet body 1, a rectification power module 2, an inverter power module 3, a DC bus capacitor module 4, a rectification current sensor 5, an inverter current sensor 6 and Laminated busbars, such as figure 1 shown. Install the rectifier power module 2, inverter power module 3, and DC bus capacitor module 4 in the cabinet body 1, and adopt the flat panel installation method, and fix them side by side on the rear wall of the cabinet body 1, and the rectifier power module 2, inverter power module 3 are respectively located on both sides of the DC bus capacitor module 4, and a back-to-back circuit structure is adopted between the three, which realizes the standardization of the main module and increases the ease of maintenance. And a back-to-back circuit structure is formed, so that the inverter power module 2 and the rectifier power module 3 are identical in structure.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com