Pollution-free laying hen feed

A technology for laying hen feed and chicken manure, applied in animal feed, animal feed, application and other directions, can solve the problems of high cost, toxic and harmful substances, affecting egg nutrition, etc. The effect of egg production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

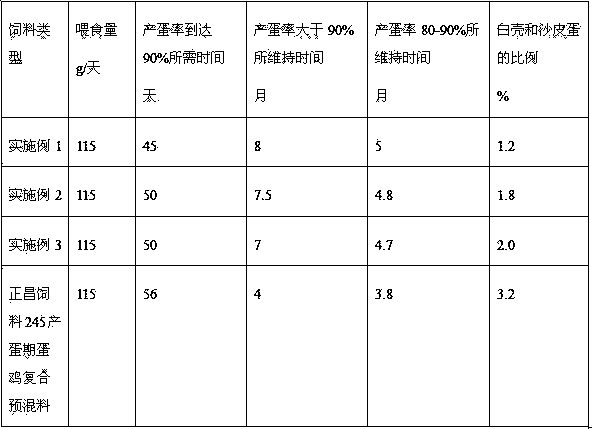

Examples

Embodiment 1

[0016] Pollution-free laying hen feed, including 100 parts of corn, 42 parts of soybean meal, 12 parts of eggshell powder, 4 parts of methionine, 33 parts of a mixture of fly maggots and chicken manure, 2.5 parts of peanut seedling powder, 0.8 parts of alfalfa powder, and 1.5 parts of mashed garlic , 6 parts of soybeans, 0.5 parts of corn stalk grass powder and 0.6 parts of duckweed grass powder, and the said parts are parts by mass.

[0017] The preparation of the eggshell powder is as follows: drying the eggshells and frying them for 35 minutes under the condition of 200-250° C., the particle size of the pulverized value is 5-10 mm.

[0018] The mixture of fly maggots and chicken manure is prepared by fermenting fresh chicken manure at 30-40° to produce maggots, drying and pulverizing when the mass content of fly maggots is 55%.

[0019] Before feeding, mix well with water whose quality and dosage are 12% of the feed quality of pollution-free laying hens.

Embodiment 2

[0021] Pollution-free laying hen feed, including 100 parts of corn, 40 parts of soybean meal, 10 parts of eggshell powder, 3 parts of methionine, 30 parts of fly maggot and chicken manure mixture, 2 parts of peanut seedling powder, 0.6 part of alfalfa grass powder, and 1 part of mashed garlic , 5 parts of soybeans, 0.5 parts of corn stalk grass powder and 0.5 parts of duckweed grass powder, and the said parts are parts by mass.

[0022] The preparation of the eggshell powder is as follows: drying the eggshells and frying them for 30 minutes under the condition of 200-250° C., the particle size of the crushed value is 5-10 mm.

[0023] The mixture of fly maggots and chicken manure is prepared by fermenting fresh chicken manure at 30-40° to produce maggots, drying and pulverizing when the mass content of fly maggots is 53%.

[0024] Before feeding, mix well with water whose quality and dosage are 10% of the feed quality of pollution-free laying hens.

Embodiment 3

[0026] Pollution-free laying hen feed, including 100 parts of corn, 45 parts of soybean meal, 15 parts of eggshell powder, 5 parts of methionine, 35 parts of fly maggot and chicken manure mixture, 3 parts of peanut seedling powder, 1 part of alfalfa grass powder, and 2 parts of mashed garlic , 7 parts of soybeans, 0.6 parts of corn stalk grass powder and 0.7 parts of duckweed grass powder, and the said parts are parts by mass.

[0027] The preparation of the eggshell powder is as follows: drying the eggshells and frying them for 40 minutes under the condition of 200-250° C., the particle size of the crushed value is 5-10 mm.

[0028] The mixture of fly maggots and chicken manure is prepared by fermenting fresh chicken manure at 30-40° to produce maggots, drying and pulverizing when the mass content of fly maggots is 53%.

[0029] Before feeding, mix well with water whose quality and dosage are 15% of the feed quality of pollution-free laying hens.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com