Triple-effect evaporation and crystallization production process and device

A technology of three-effect evaporation and production equipment, which is applied in the direction of multi-effect evaporation and solution crystallization, can solve the problems of high discharge temperature of distilled water and condensed water, high cost of environmental protection and prevention, and large consumption of cooling water, so as to reduce emissions , It is not easy to scar, and the effect of reducing the amount of heating steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

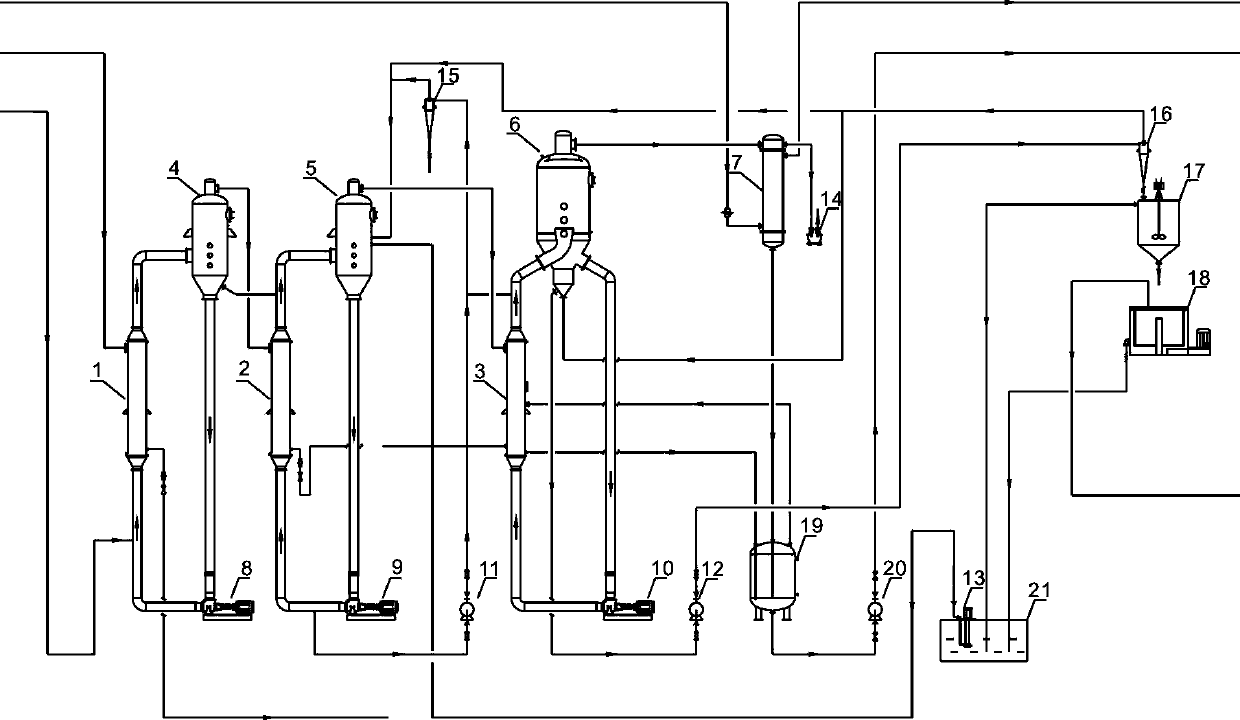

[0039]The top of the first-effect heating chamber 1 is connected to the first-effect separation chamber 4 through the feeding pipeline, and the bottom of the first-effect separation chamber 4 is connected to the first-effect axial flow pump 8 through the feeding pipe, and then connected to the bottom of the first-effect heating chamber 1; the first-effect separation The top of the chamber 4 is connected to the upper part of the second-effect heating chamber 2 through the pipeline, the top of the second-effect heating chamber 2 is connected to the second-effect separation chamber 5 through the feeding pipeline, and the bottom of the second-effect separation chamber 5 is connected to the second-effect axial flow pump 9 through the feeding pipe. After the connection, it is connected with the bottom of the second-effect heating chamber 2; the top of the second-effect separation chamber 5 is connected with the upper part of the third-effect heating chamber 3 through a line pipeline, ...

Embodiment 2

[0047] Raw material: calcium formate solution, composition: calcium formate ~14%, water and others ~86%, temperature: 30°C,

[0048] Output: steamed water volume: 1000kg / h, product: calcium formate crystal,

[0049] Raw steam: saturated steam: pressure 0. 3~0.4MPaG

[0050] Circulating water system: the upper water temperature is 32°C, the return water temperature is 38°C, and the upper water pressure is 0.4MPaG.

[0051] The specific operation is as follows:

[0052] Open the cooling water valves of the mechanical seals of each pump. The mechanical seals cannot operate without cooling liquid. Check that all valves are closed;

[0053] Check the supply pressure of the circulating cooling water, open the valve of the indirect condenser shell-side venting pipeline, and discharge the non-condensable gas on the shell side; feed the circulating cooling water, check whether the temperature, pressure, and return water temperature of the circulating cooling water are accurate ;

...

Embodiment 3

[0077] Concrete implementation steps are with embodiment 2, and other data are as follows:

[0078] Feed calcium formate 2.75m 3 / h, concentration 14%, steam flow 634 kg / h;

[0079] One effect: temperature 90℃, pressure: -40kpa;

[0080] Second effect: temperature 72°C, pressure: -67kpa;

[0081] Three effects: temperature 53°C, pressure: -86kpa;

[0082] At this time, the amount of steamed water: 1.320t / h;

[0083] The steam consumption ratio: 0.48 (t steam / t water);

[0084] From the above results, the steam consumption ratio of the three-effect evaporation system can be determined: 0.45-0.5 (t steam / t water).

[0085] Using the above process and steps, the yield can reach 88% and above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com