Ultra-smooth plane grinding polishing device and method for online trimming flexible polishing pad

A flexible polishing and plane grinding technology, which is used in abrasive surface adjustment devices, grinding/polishing equipment, and parts of grinding machine tools, etc. problem, to achieve the effect of high-efficiency polishing and high-efficiency grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

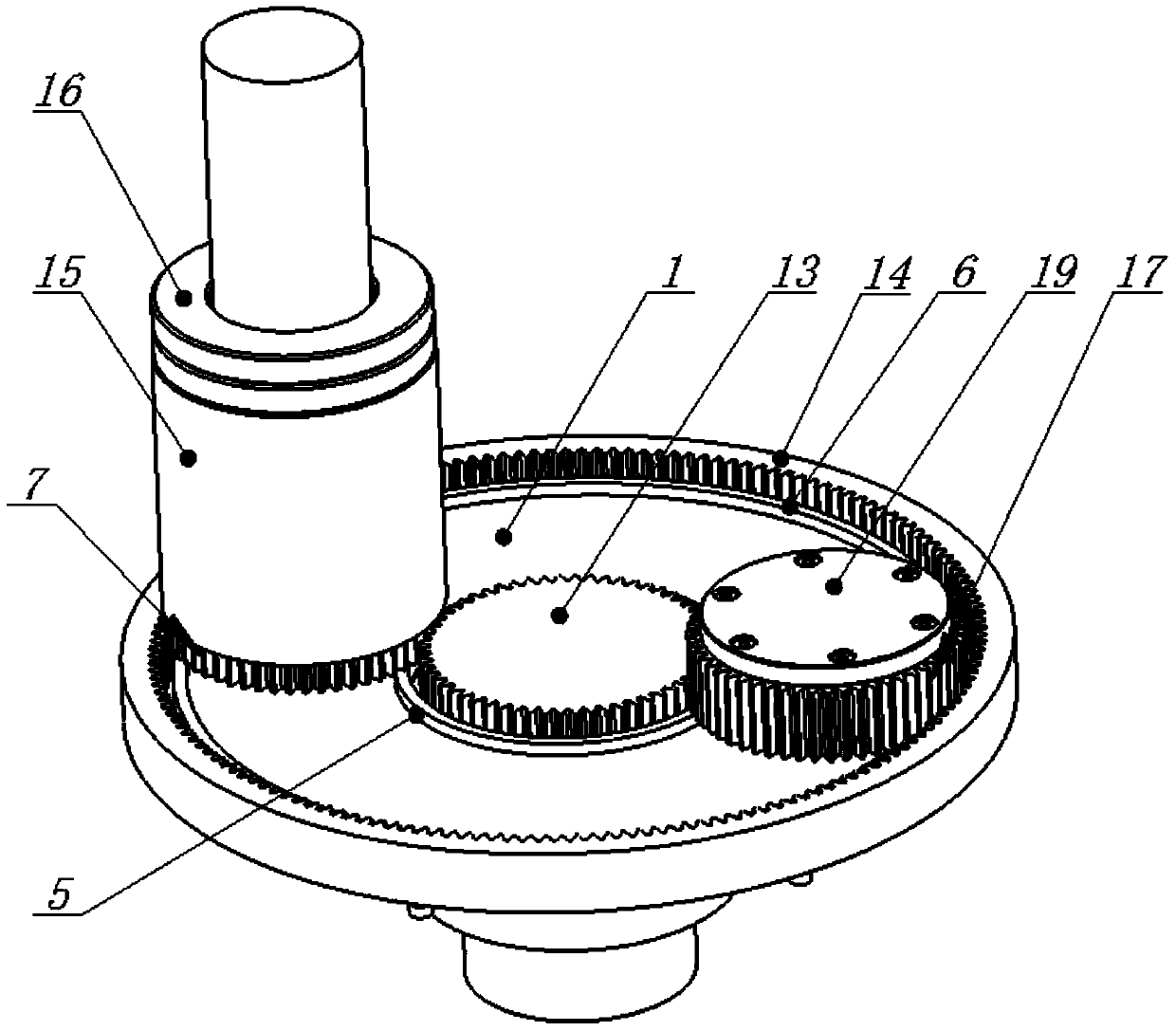

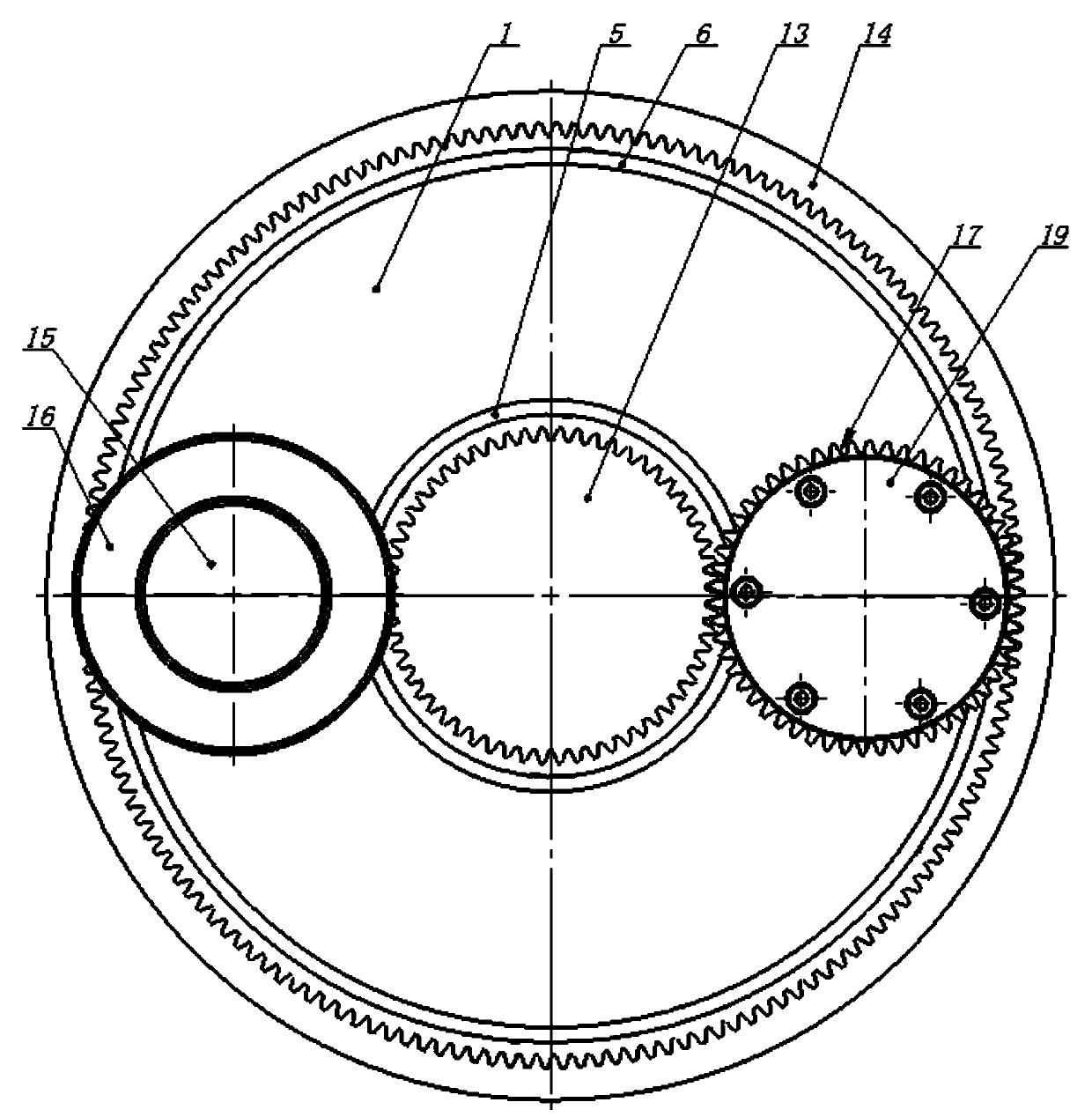

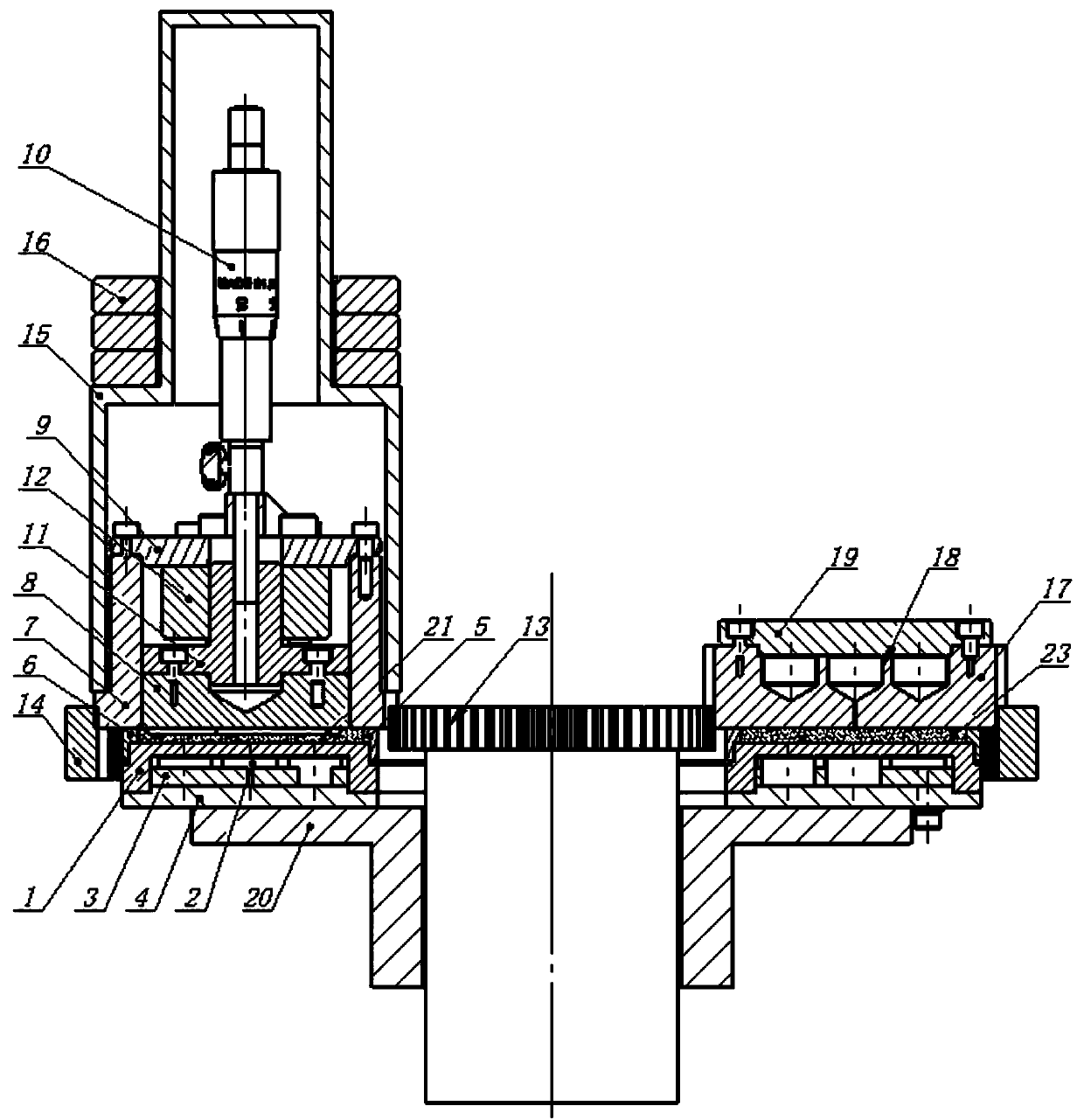

[0026] Such as Figure 1 ~ Figure 3As shown, an ultra-smooth surface grinding and polishing device for online dressing of a flexible polishing pad of the present invention includes a cluster magnetorheological abrasive semi-fixed flexible polishing pad generating device, a workpiece clamping and gap adjustment mechanism, and a real-time dressing device for a flexible polishing pad. The cluster magnetorheological abrasive semi-fixed flexible polishing pad generating device includes an annular grinding disc 1, a cluster magnetic pole 2, a separation disc 3, a lower end cover 4, and a turntable 20. The workpiece clamping and gap adjustment mechanism includes an inner support ring 5 and an outer support ring. Ring 6, reference star wheel 7, moving cylinder 8, upper end cover 9, depth gauge 10, coupling shaft 11, expansion sleeve 12, internal gear 13, external gear 14, flexible polishing pad real-time dressing device includes a dressing star wheel 17. The magnetic pole 18 embedded ...

Embodiment 2

[0047] The structure of the present invention is the same as that of Embodiment 1, except that the magnetic induction intensity of the cluster magnetic pole 2 end face is 3000GS, and the magnetic induction intensity of the magnetic pole 18 end face is 100GS. The square permanent magnets with a side length of 25 mm of the cluster strong magnetic pole 2 are distributed in a cluster array with a center distance of 30 mm, such as Image 6 shown.

[0048] The present invention prepares the magnetorheological fluid 23 by the following method: adding strontium oxide abrasives with a median particle size of 500 nanometers at a concentration of 6% and strontium oxide abrasives with a median particle size of 7 microns at a concentration of 12% in deionized water, Carbonyl iron powder with a median particle size of 5 microns at a concentration of 10%, carbonyl iron powder with a median particle size of 200 nm at a concentration of 5%, dispersant at a concentration of 4%, and antirust age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com