Method for preparation of benzene, toluene and xylene from ethene cracking C9

A technology of ethylene cracking and xylene, which is applied in the direction of hydrocarbon cracking, hydrocarbon oil treatment, organic chemistry, etc., can solve the problems of high indene content, high unsaturated aromatics, complex aromatics composition, etc., and achieve the purpose of inhibiting dehydrogenation condensation reaction, Effects of reducing coke and carbon deposits and preventing hydrogenation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1 Aromatic hydrocarbon extraction

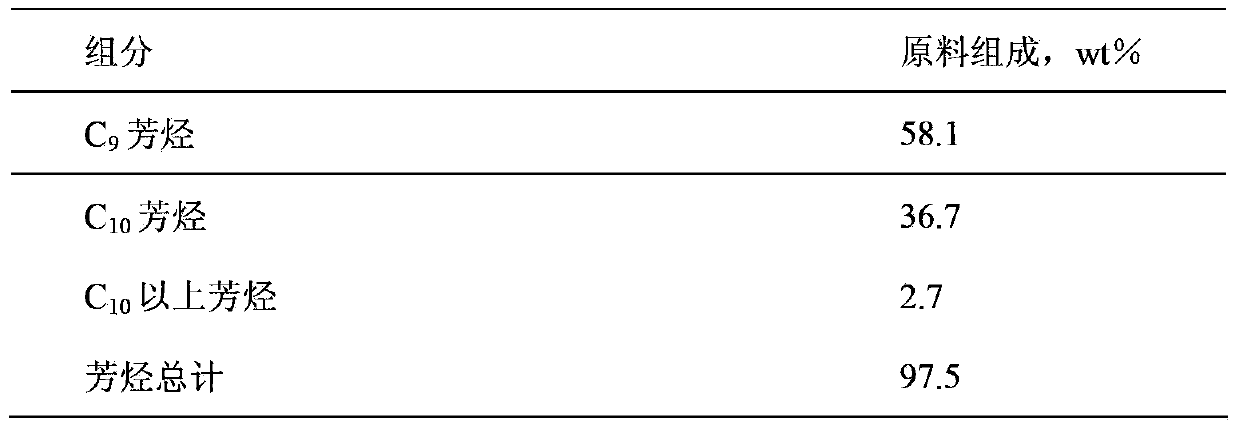

[0014] Ethylene cracking C 9 Raw material density 0.95g / ml; distillation range 110-220℃; aromatics content 53%;

[0015] The inner diameter of the column is 20mm, the packing used is a 2x2 θ ring, and the packing height is 2.2m. There are three tower sections in total, with an external heat insulation jacket, and the insulation temperature is 65°C. The extraction agent is tetraethylene glycol (4wt% water): the feeding position is the upper half of the tower, and the flow rate is 600 g / h. Feed temperature~60℃; ethylene cracking C 9 + The raw material flow rate is 100 g / hour, the feeding temperature is 60 °C, and the feeding position is the lower half of the extraction column.

[0016] Aromatic-rich solvent flows out from the bottom of the column. The raffinate is drained from the top of the column. Top discharge was set at 45 g / hr and bottom discharge was set at 655 g / hr. The raffinate aromatics content was 3.6%. Adjust...

Embodiment 2

[0017] Example 2. Extraction agent recovery

[0018] The extraction agent recovery column, the inner diameter of the column is 20mm, the packing used is 2x2 theta ring, the packing height is 1.4m, and it has an external heat insulation jacket. In this column, aromatics are removed from the extractant. The aromatic-rich solvent is fed from the middle of the column, and the fractions at 135-220° C. are collected and discharged from the top of the column after condensation. The reflux ratio (return flow / outflow flow) was set to 10. The lean extractant obtained at the bottom of the column was cooled to 80°C in a downstream cooler and flowed into a buffer tank. The extraction agent is injected into the extraction column from the buffer tank by the metering pump and recycled.

[0019] Through the above process, the isolated C 9 + Aromatic content is ≧ 99.2% by weight.

Embodiment 3

[0020] Example 3 Preparation of Pre-hydrogenation Catalyst for Extracting Aromatic Hydrocarbons

[0021] Take 60.0 grams of Na-type MCM-56 zeolite and 25.716 grams of γ-Al 2 O 3 Mixing, adding 40 ml of water, kneading, extruding, drying at 120°C for 12 hours, and calcining at 540°C for 6 hours in air to obtain a carrier. Then, using 100% water vapor, at 550° C., 5 g per gram of catalyst per hour per gram of water passed through the carrier and passivated for 5 hours to obtain a passivated catalyst carrier. Use 3.73 g of analytically pure nickel nitrate, 0.917 g of analytically pure chromium nitrate, 0.387 g of analytical magnesium nitrate and 35 ml of deionized water to form an impregnation solution, impregnate the above-mentioned carrier in equal volume at room temperature for 24 hours, and dry at 120 ° C Catalyst A was obtained after calcination at 500°C for 6 hours in air for 12 hours. Use 6.21 g of analytically pure nickel nitrate, 1.38 g of analytically pure chromium n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com