Anti-vanadium auxiliary agent of heavy oil cracking catalyst or contact agent

A heavy oil cracking and catalyst technology, applied in cracking, catalytic cracking, petroleum industry and other directions, can solve the problems of destroying molecular sieves and adding a large amount of anti-vanadium additives, and achieve the effect of improving anti-vanadium ability, low cost and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The anti-vanadium additive A is Ge, and the orbit-3000 heavy oil catalytic cracking catalyst (commercial product of China Petroleum & Chemical Co. 2 / g, the same below) Mix the catalyst with the anti-vanadium additive A, and the weight of the anti-vanadium additive A in the mixture is 1% of the weight of the catalyst.

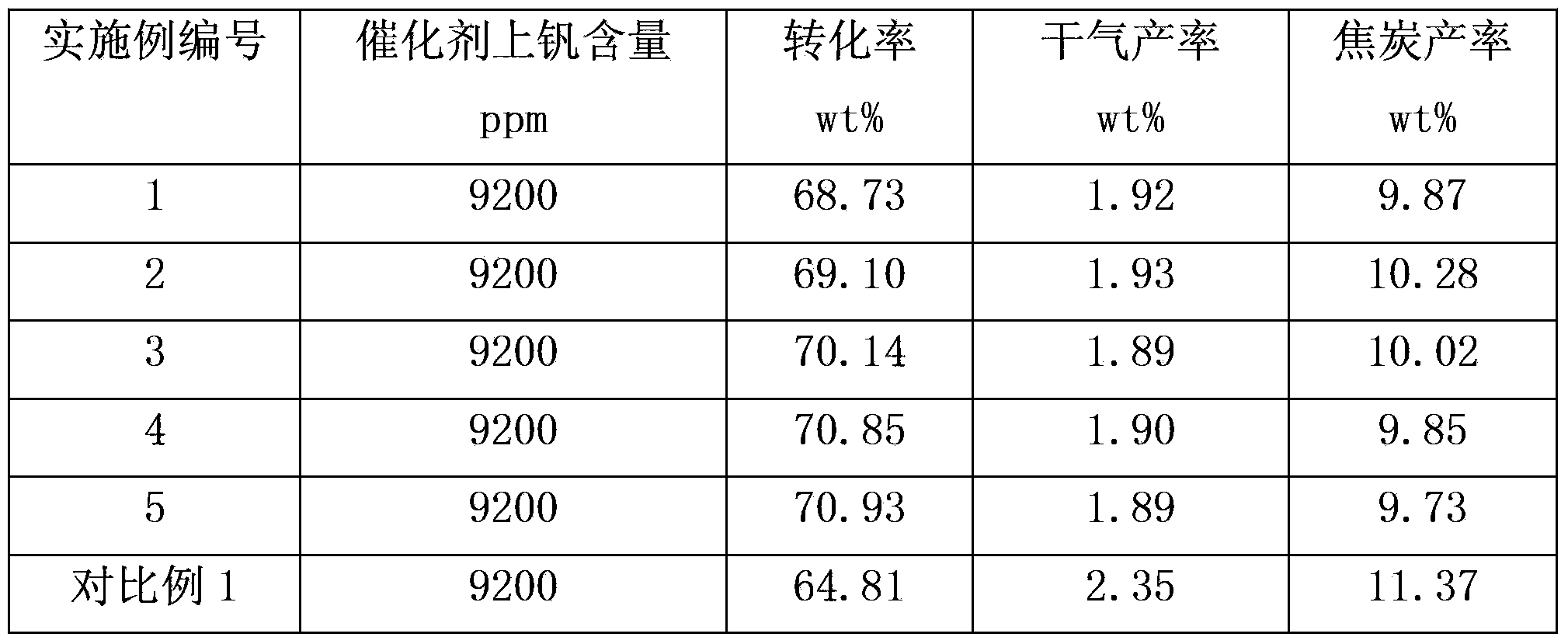

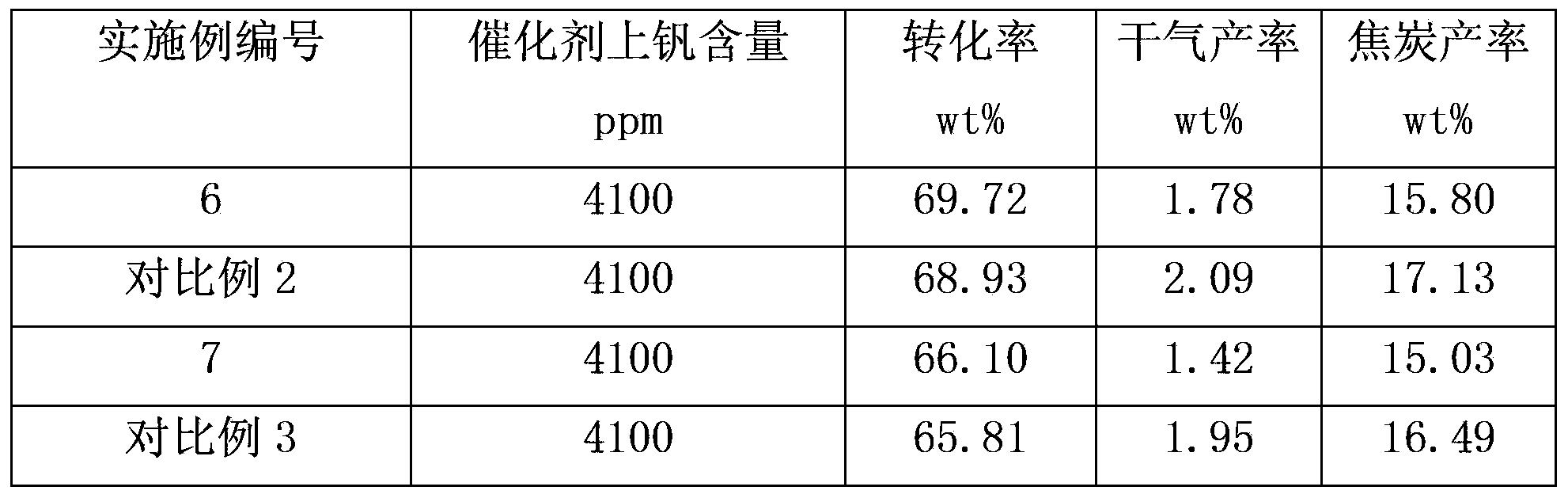

[0025]A small-scale fixed fluidized bed catalytic cracking test was carried out, using 50wt% Tahe residual oil containing 220ppm vanadium and 50wt% kerosene as raw material (see Table 1 for the properties of the raw material oil) and after 20 reaction-regeneration cycles, the equilibrium 9200 ppm vanadium was deposited on the catalyst.

[0026] The fixed fluidized bed reaction conditions are: reaction temperature 500°C, regeneration temperature 700°C, agent-oil ratio 4.0, space velocity 20h -1 , Catalyst loading 150g.

[0027] The evaluation results of the fixed fluidized bed are listed in Table 2. The characterization results of the catalyst after th...

Embodiment 2

[0029] Anti-vanadium additive B is GeO 2 , mix the orbit-3000 heavy oil catalytic cracking catalyst with the anti-vanadium additive B, and the weight of the anti-vanadium additive B in the mixture is 0.2% of the weight of the catalyst.

[0030] A small-scale fixed fluidized bed catalytic cracking test was carried out, using 50wt% Tahe residual oil containing 220ppm vanadium and 50wt% kerosene as raw material (see Table 1 for the properties of the raw material oil) and after 20 reaction-regeneration cycles, the equilibrium 9200 ppm vanadium was deposited on the catalyst.

[0031] The fixed fluidized bed reaction conditions are: reaction temperature 500°C, regeneration temperature 700°C, agent-oil ratio 4.0, space velocity 20h -1 , Catalyst loading 150g.

[0032] The evaluation results of the fixed fluidized bed are listed in Table 2. The characterization results of the catalyst after the test are shown in Table 3.

Embodiment 3

[0034] The anti-vanadium additive C is MnO, the orbit-3000 heavy oil catalytic cracking catalyst is mixed with the anti-vanadium additive C, and the weight of the anti-vanadium additive C in the mixture is 0.7% of the weight of the catalyst.

[0035] A small-scale fixed fluidized bed catalytic cracking test was carried out, using 50wt% Tahe residual oil containing 220ppm vanadium and 50wt% kerosene as raw material (see Table 1 for the properties of the raw material oil) and after 20 reaction-regeneration cycles, the equilibrium 9200 ppm vanadium was deposited on the catalyst.

[0036] The fixed fluidized bed reaction conditions are: reaction temperature 500°C, regeneration temperature 700°C, agent-oil ratio 4.0, space velocity 20h -1 , Catalyst loading 150g.

[0037] The fixed fluidized bed results are listed in Table 2. The characterization results of the catalyst after the test are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com