A car filter paper made of coal gangue and fly ash inorganic fiber and its preparation method

An inorganic fiber, fly ash technology, applied in the direction of inorganic fiber/sheet, synthetic cellulose/non-cellulose material pulp/paper, filter paper, etc. Low efficiency, affecting the service life and other problems, to achieve the effect of good water resistance, strong rigidity, good temperature resistance and filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

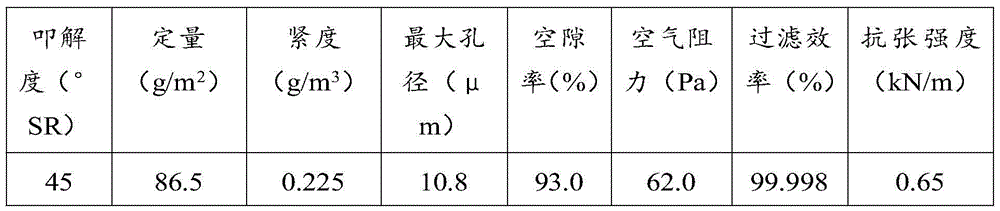

Examples

Embodiment 1

[0031] An automobile filter paper made of coal gangue and fly ash inorganic fiber, and its raw material components include:

[0032] Coal gangue and fly ash inorganic fiber 25%, wood pulp fiber 45%, PVA fiber 5%, silane coupling agent YDH-151: 10%, polyoxyethylene 5%, silicone oil 10%.

[0033] The preparation method includes the following steps:

[0034] Step S01: The coal gangue and fly ash inorganic fiber are softened and modified with silane coupling agent YDH-151 in water, and polyoxyethylene is added. In the hydraulic pulper, they are lightly beaten to make a dispersion, and lightly beaten. Specifically: at a speed of 890 rpm, after stirring for 17 minutes, add water to make a dispersion with a solid content of 4.5%;

[0035] Step S02: mix wood pulp fibers and PVA fibers in parts by weight, add silicone oil, put them in a pulper at a speed of 950 revolutions / min, stir for 23 minutes, and then add water to prepare a slurry with a solid content of 5.8%;

[0036] Step S03: Add the c...

Embodiment 2

[0038] An automobile filter paper made of coal gangue and fly ash inorganic fiber, and its raw material components include:

[0039] Coal gangue and fly ash inorganic fiber 20%, wood pulp fiber 66%, PVA fiber 2%, silane coupling agent YDH-151: 10%, polyoxyethylene 1%, silicone oil 1%.

[0040] The preparation method includes the following steps:

[0041] Step S01: The coal gangue and fly ash inorganic fiber are softened and modified with silane coupling agent YDH-151 in water, and polyoxyethylene is added. In the hydraulic pulper, they are lightly beaten to make a dispersion, and lightly beaten. Specifically: at a speed of 800 revolutions per minute, after stirring for 15 minutes, add water to make a dispersion with a solid content of 4.5%;

[0042] Step S02: mix wood pulp fibers and PVA fibers in parts by weight, add silicone oil, put them into the pulper at 900 rpm, stir for 20 minutes, and then add water to prepare a slurry with a solid content of 5%;

[0043] Step S03: Add the coal...

Embodiment 3

[0045] An automobile filter paper made of coal gangue and fly ash inorganic fiber, and its raw material components include:

[0046] Coal gangue and fly ash inorganic fiber 20%, wood pulp fiber 70%, PVA fiber 2%, silane coupling agent YDH-151:1%, polyoxyethylene 1%, silicone oil 6%.

[0047] The preparation method includes the following steps:

[0048] Step S01: The coal gangue and fly ash inorganic fiber are softened and modified with silane coupling agent YDH-151 in water, and polyoxyethylene is added. In the hydraulic pulper, they are lightly beaten to make a dispersion, and lightly beaten. Specifically: at a speed of 870 revolutions / minute revolutions / minute, after stirring for 18 minutes, add water to make a dispersion with a solid content of 4.7%;

[0049] Step S02: mix wood pulp fibers and PVA fibers in parts by weight and add silicone oil, put them in a pulper at a speed of 970 rpm, stir for 21 minutes, and then add water to prepare a slurry with a solid content of 5.6%;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| wind resistance | aaaaa | aaaaa |

| wind resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com