Pipe-to-soil potential excessively-negative control method and device for buried pipeline

A technology of buried pipeline and pipe-to-ground potential, which is applied to control/regulating systems, regulating electrical variables, instruments, etc., to achieve the effect of convenient installation and maintenance, small device size, and solving instantaneous large interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

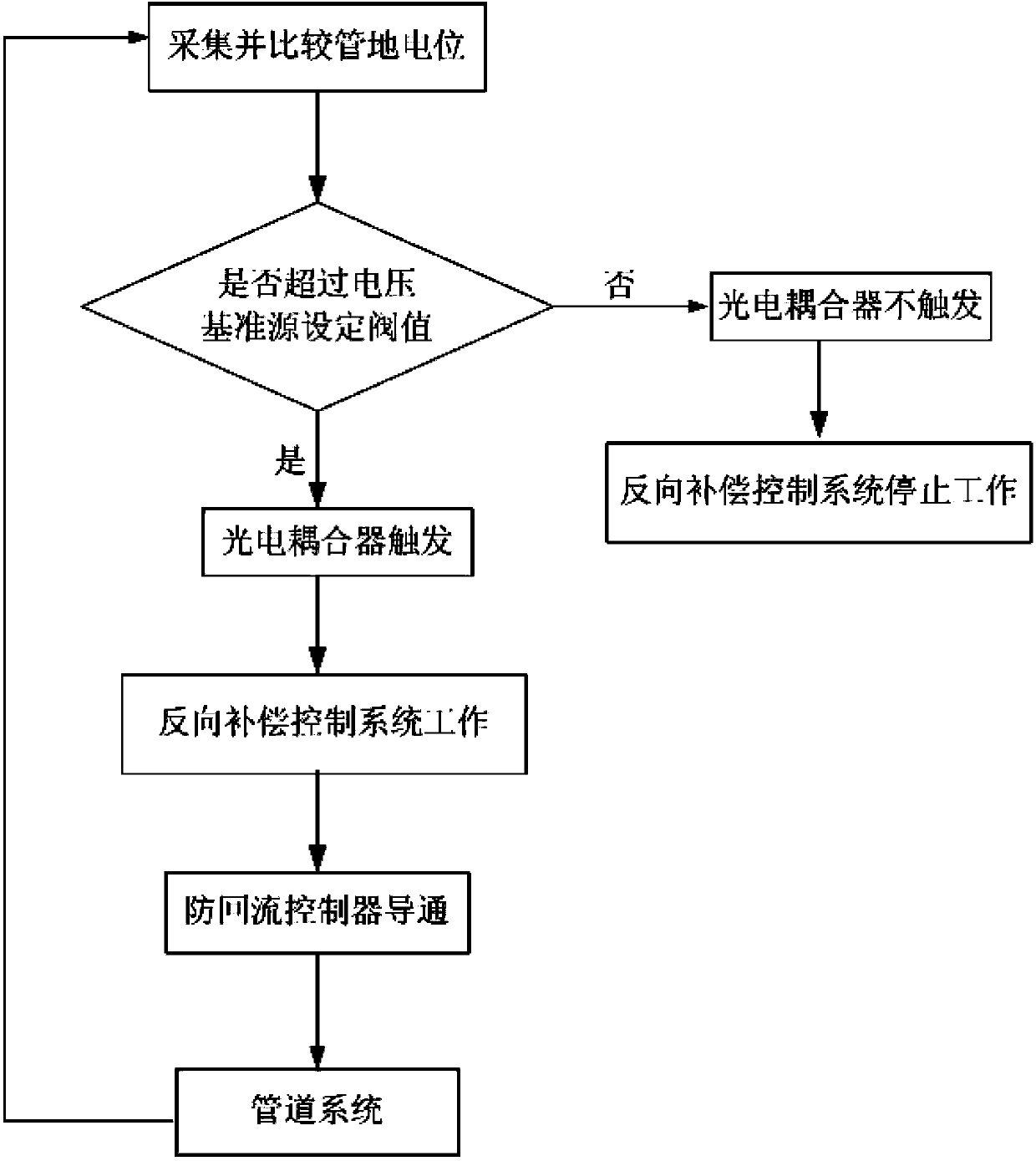

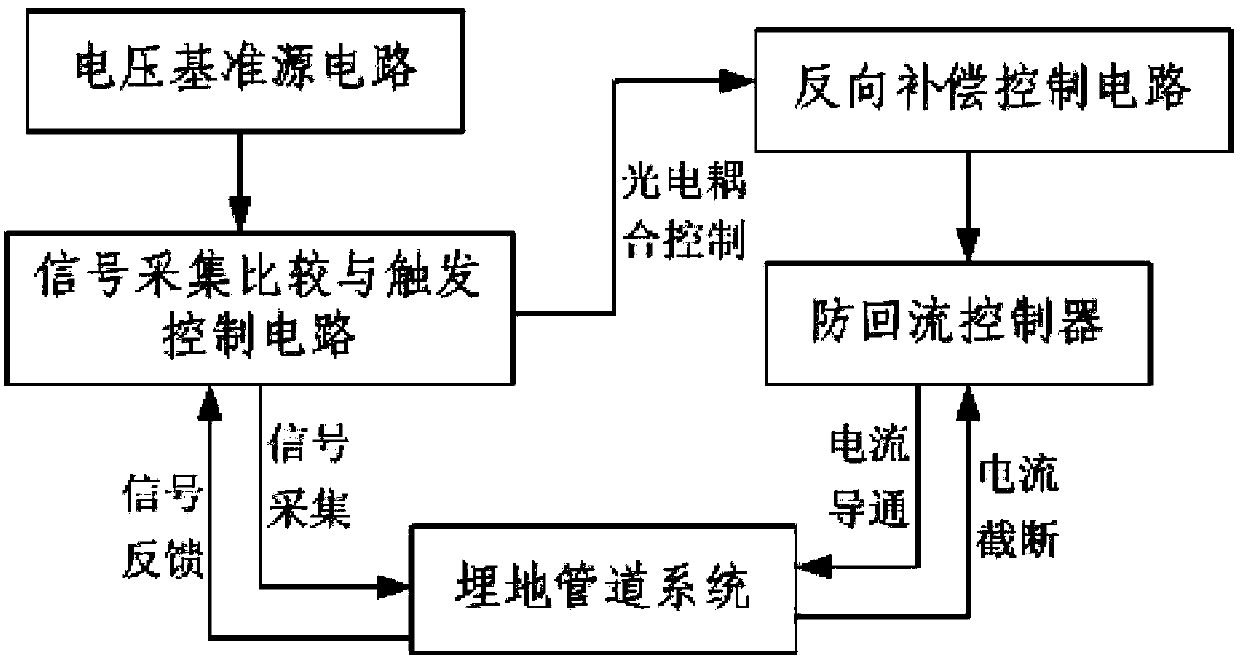

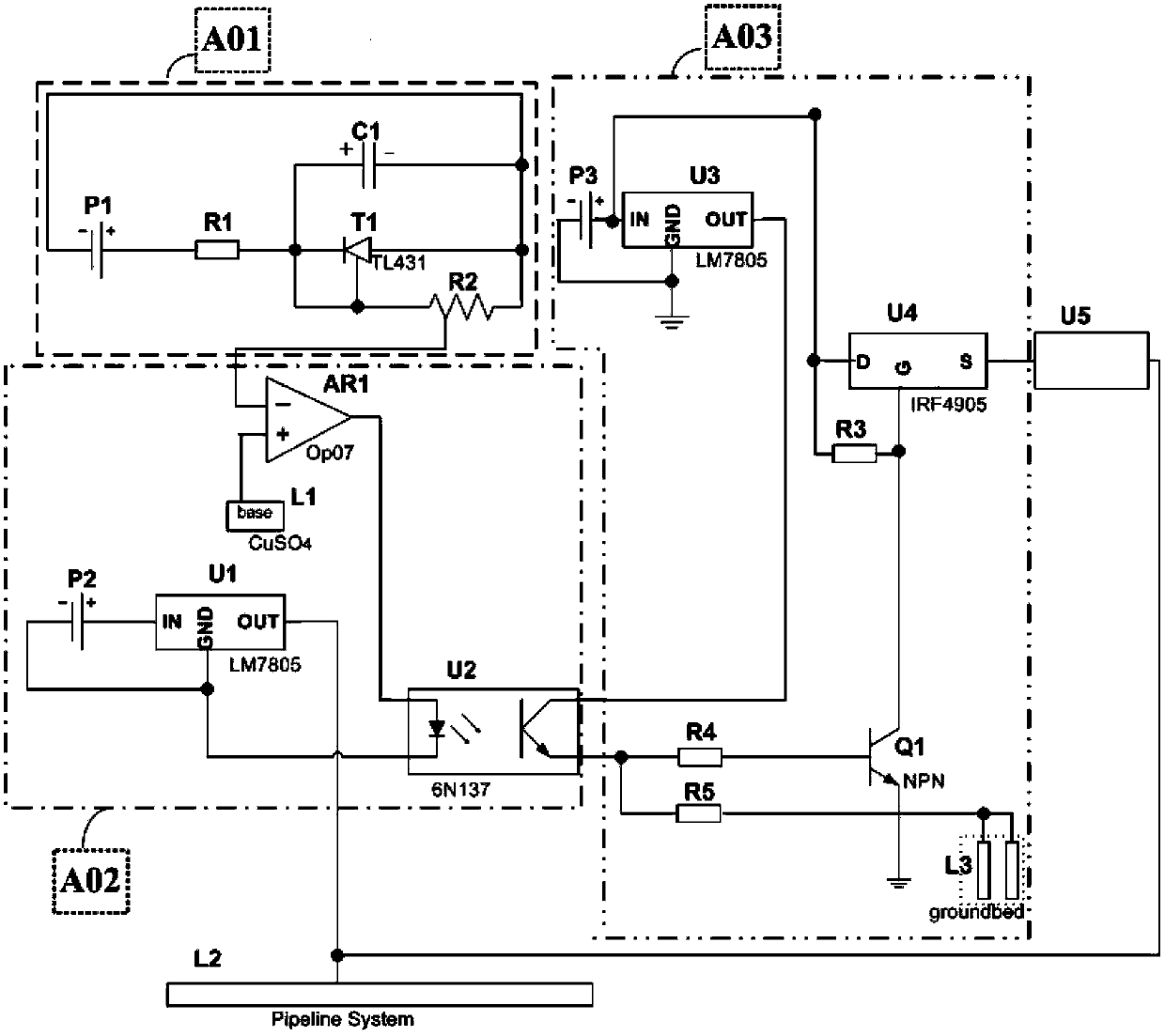

[0025] Embodiment. Below in conjunction with accompanying drawing, the invention will be further described. This example is a test prototype, and the principle of the buried pipeline ground potential over-negative control device is as follows: figure 2 shown. The output of the voltage reference original circuit is connected to the signal acquisition comparison and trigger control circuit, and the signal acquisition comparison and trigger control circuit continuously performs signal acquisition and signal feedback of the pipe-ground potential with the buried pipeline system, and the output of the signal acquisition comparison and trigger control circuit is passed through the photoelectric The coupling control is connected to the reverse compensation control circuit, the output of the reverse compensation control circuit is connected to the anti-backflow controller, the output of the anti-backflow controller is connected to the buried pipeline system, and the diode inside the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com