Preparation method for feed using squid internal organs as raw material and prepared feed using same

A technology of squid viscera and feed, applied in animal feed, animal feed, application and other directions, to achieve the effect of enhancing natural immunity, easy digestion and absorption, and preventing diarrhea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

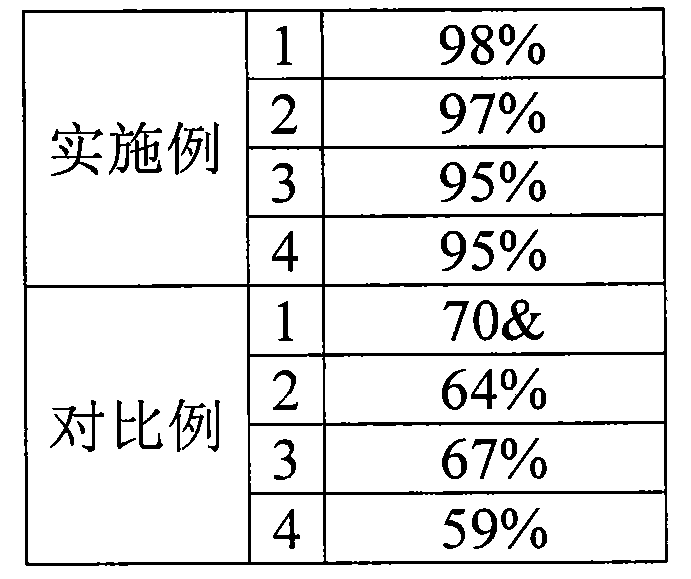

Examples

Embodiment 1

[0022] (1) Homogenize the squid viscera and mix it with water to obtain a 3mg / ml solution, then mix it with calcium hydrogen phosphate and sodium alginate, stir for 3 hours, and filter to obtain the filtrate; the amount of calcium hydrogen phosphate added is the mass of squid viscera 5%, the addition of sodium alginate is 7% of squid mass;

[0023] (2) step (1) is obtained filtrate, pumice powder and papain are mixed homogeneously, and the addition of pumice powder is 20% of squid viscera quality, and the addition of papain is 520U / g squid viscera, and the adjustment pH value is 6, Stir at 53°C and 200°C for 6.5h;

[0024] (3) add allicin, the addition amount of allicin is 10% of squid mass, stir 43-5h under the condition of 45 ℃, then add ferric sulfate, stir, stirring speed is 300-400rpm, filter to obtain filter residue;

[0025] (4) Freeze-dry at -5°C.

Embodiment 2

[0027] (1) Homogenize the squid viscera and mix it with water to obtain a 1mg / ml solution, then mix it with calcium hydrogen phosphate and sodium alginate, stir for 1 hour, and filter to obtain the filtrate; the amount of calcium hydrogen phosphate added is the mass of squid viscera 1%, the addition of sodium alginate is 16% of squid mass;

[0028] (2) step (1) is obtained filtrate, pumice powder and papain are mixed homogeneously, and the addition of pumice powder is 20% of squid viscera quality, and the addition of papain is 520U / g squid viscera, and the adjustment pH value is 6, Stir at 53°C and 200°C for 6.5h;

[0029] (3) add allicin, the addition of allicin is 15% of squid mass, stir 5h under the condition of 4540-50 ℃, then add ferric sulfate, stir, stirring speed is 400rpm, filter to obtain filter residue;

[0030] (4) Freeze-dry at -15°C.

Embodiment 3

[0032] (1) Homogenize the squid viscera and mix it with water to obtain a 1mg / ml solution, then mix it with calcium hydrogen phosphate and sodium alginate, stir for 3 hours, and filter to obtain the filtrate; the amount of calcium hydrogen phosphate added is the mass of squid viscera 1%, the addition of sodium alginate is 16% of squid mass;

[0033] (2) step (1) is obtained filtrate, pumice powder and papain are mixed homogeneously, and the addition of pumice powder is 26% of squid viscera quality, and the addition of papain is 500U / g squid viscera, and the adjustment pH value is 5.8, Stirring at 50°C and 300rpm for 7h;

[0034] (3) add allicin, the addition of allicin is 5% of squid mass, stir 3h under the condition of 50 ℃, then add ferric sulfate, stir, stirring speed is 400rpm, filter to obtain filter residue;

[0035] (4) Freeze-dry at -5°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com