Coal-fired boiler SCR (Selective Catalytic Reduction) denitration control method and system

A technology of coal-fired boilers and control methods, applied in various fluid ratio control, separation methods, chemical instruments and methods, etc., can solve problems such as excessive, extensive control, and insufficient ammonia injection, so as to reduce standard deviation and extend service life The effect of life, safety and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

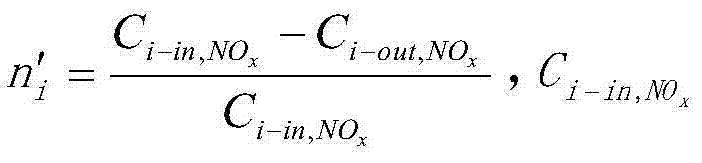

[0027] As a control method, the present invention is different from the existing control methods. The molar ratio of ammonia nitrogen before the catalyst is selected as the feedforward amount, and the molar ratio of ammonia nitrogen is preset as the target, and the regulating valve of the ammonia injection device is controlled by an automatic control algorithm such as PID control. To control the amount of ammonia injection.

[0028] Specifically, the ammonia nitrogen molar ratio before the catalyst is the product of the ratio between the NOx concentration and the ammonia concentration before the catalyst and the ratio of the corresponding molar value; Ratio of former NOx concentration.

[0029] The control introduces the preset NOx concentration, the NOx concentration before the catalyst and the ammonia concentration, which can ensure that there will be no excessive or insufficient ammonia injection to the greatest extent, and then reduce the ammonia consumption while ensuring...

Embodiment 2

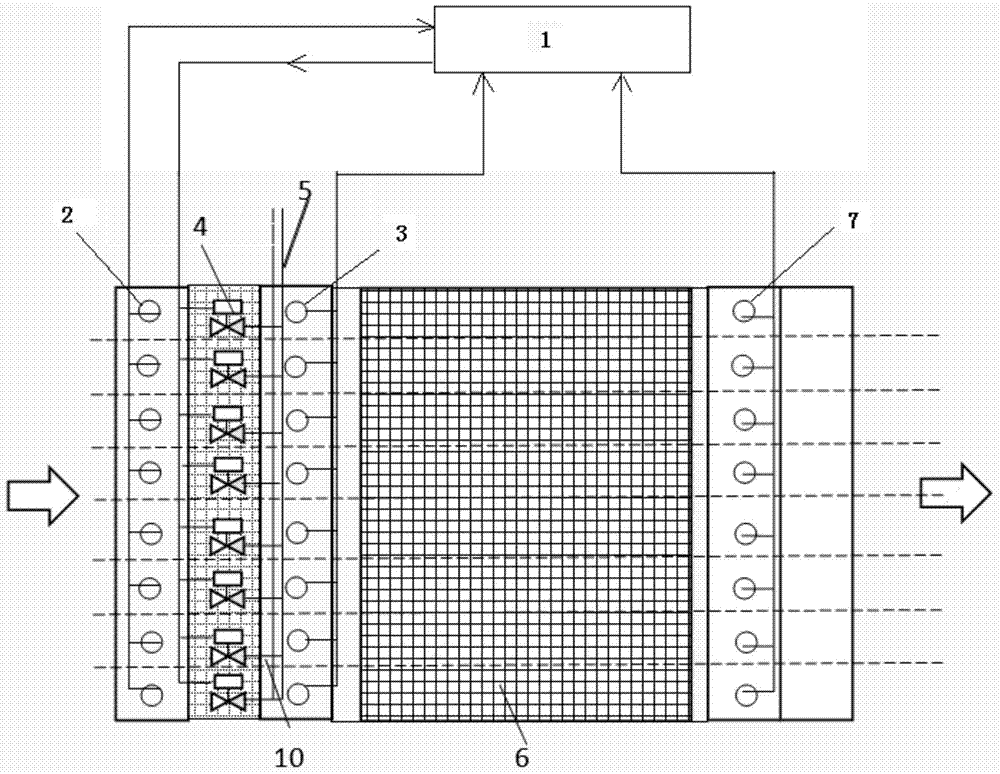

[0031] Such as figure 1 Shown is a coal-fired boiler SCR denitrification system according to an embodiment of the present invention, including a flue gas inlet chamber, a catalyst chamber, and a flue gas outlet chamber connected in sequence. The vertical section of the coal-fired boiler SCR denitrification system in the flue gas advancement The upper part is divided into several areas, and the flue gas inlet chamber corresponding to each area is equipped with a corresponding ammonia injection device, a NOx concentration detection device 2 before the catalyst, and an ammonia concentration detection device 3 before the catalyst, and the ammonia concentration detection device 3 before the catalyst is installed Downstream of the ammonia plant.

[0032] The ammonia injection device includes several nozzles, the nozzles are connected to the ammonia injection main pipe 5, and a regulating valve 4 is arranged on the ammonia injection branch between the ammonia injection main pipe and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com