Preparation method and application of atractylodes lancea volatile oil microcapsules

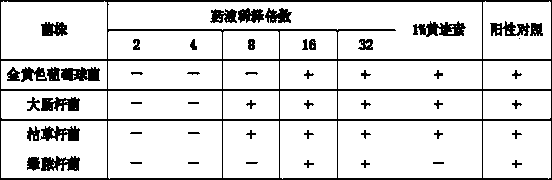

A technology of Atractylodes volatile oil and microcapsules, which is applied in the field of medicine, can solve problems such as no public literature reports, and achieve improved stability, solubility and dispersibility, and strong antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add wall material maltodextrin and sodium alginate to hot water at 70°C to prepare solutions with mass ratios of maltodextrin, sodium alginate and water of 5g / 100g and 10g / 100g, stir well, and wait for complete dissolution for later use Use; get the volatile oil of Atractylodes Rhizoma Atractylodis, determine that the mass ratio of the microcapsule wall material and core material that is evenly mixed for standby use is 5g / g, then add the mixed emulsifier of monoglyceride and sucrose ester, and determine that the mass ratio of the wall material and emulsifier is 0.2g Add the core material Atractylodis volatile oil to the above solution while stirring, and use high-pressure homogenization equipment to homogenize the wall material solution added with Atractylodes volatile oil at a temperature of 70 ° C and a pressure of 15 MPa twice, each time for 5 minutes, Obtain the emulsion; put the homogenized emulsion into the ultrasonic equipment, control the ultrasonic power to 50W,...

Embodiment 2

[0020] Add wall material maltodextrin and sodium alginate to hot water at 60°C to prepare solutions with mass ratios of maltodextrin, sodium alginate and water of 15g / 100g and 5g / 100g, stir evenly, and wait for complete dissolution for later use Use; get the volatile oil of Atractylodes atractylodis, determine that the mass ratio of the microcapsule wall material and core material that is evenly mixed for standby use is 10g / g, then add the mixed emulsifier of monoglyceride and sucrose ester, and determine that the mass ratio of the wall material to the emulsifier is 0.1g Add the core material Atractylodis volatile oil to the above solution while stirring, and use high-pressure homogenization equipment to homogenize the wall material solution added with Atractylodes volatile oil at a temperature of 80°C and a pressure of 25MPa twice, each time for 7min, Obtain the emulsion; put the homogenized emulsion into the ultrasonic equipment, control the ultrasonic power to 100W, the ultr...

Embodiment 3

[0022] Add wall material maltodextrin and sodium alginate to hot water at 80°C to prepare solutions with mass ratios of maltodextrin, sodium alginate and water of 10g / 100g and 11g / 100g, stir evenly, and wait for complete dissolution for later use Use; get the volatile oil of Atractylodes Rhizoma Atractylodis, determine that the mass ratio of the microcapsule wall material and core material that is evenly mixed for standby use is 8g / g, then add the mixed emulsifier of monoglyceride and sucrose ester, and determine that the mass ratio of the wall material and emulsifier is 0.15g Add the core material Atractylodis volatile oil to the above solution while stirring, and use high-pressure homogenization equipment to homogenize the wall material solution added with Atractylodes volatile oil at a temperature of 90°C and a pressure of 20MPa twice, each time for 6min, Obtain the emulsion; put the homogenized emulsion into the ultrasonic equipment, control the ultrasonic power to 80W, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com