Platinum-based catalyst, preparation method and application thereof, and preparation method for propylene

A catalyst and platinum-based technology, which is applied in the field of platinum-based catalysts and their preparation, can solve the problems of complex preparation process, long preparation time, and poor dispersion of catalyst active components, etc. Simple, evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

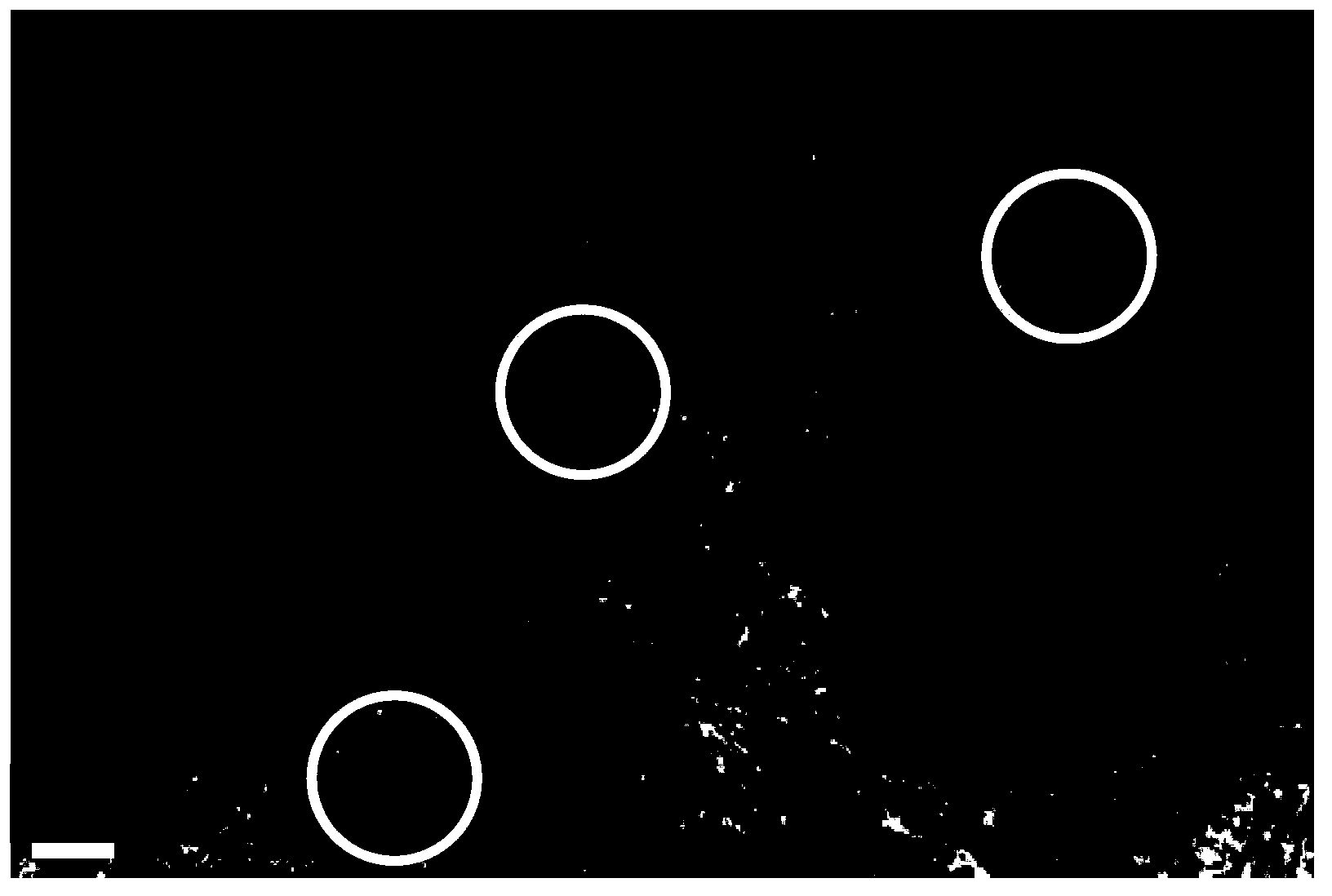

[0049] (1) Weigh 0.0341g of SnCl 2 2H 2 Dissolve O in 2.4mL deionized water to make a solution, and weigh 3g of γ-Al at the same time 2 o 3 Add the above solution. Then put it into an ultrasonic instrument, adjust the water temperature to 40°C, and ultrasonically vibrate for 2 hours. The sonicated samples were dried in an oven at 110° C. for 2 hours. Finally, the dried sample was placed in a muffle furnace at a rate of 2°C / min to 500°C, baked in air for 5 hours, and cooled to room temperature.

[0050] (2) Dissolve 2.4mL of 0.01g / mL chloroplatinic acid solution in the calcined sample, put it into the ultrasonic instrument, adjust the water temperature to 40°C, and turn on the ultrasonic vibration for 2 hours. The sonicated samples were dried in an oven at 110° C. for 2 hours. Finally, the dried sample was placed in a muffle furnace at a rate of 2°C / min to 500°C, baked in air for 5 hours, and cooled to room temperature.

[0051] Catalyst Cat#1 was produced.

[0052] Pla...

Embodiment 2

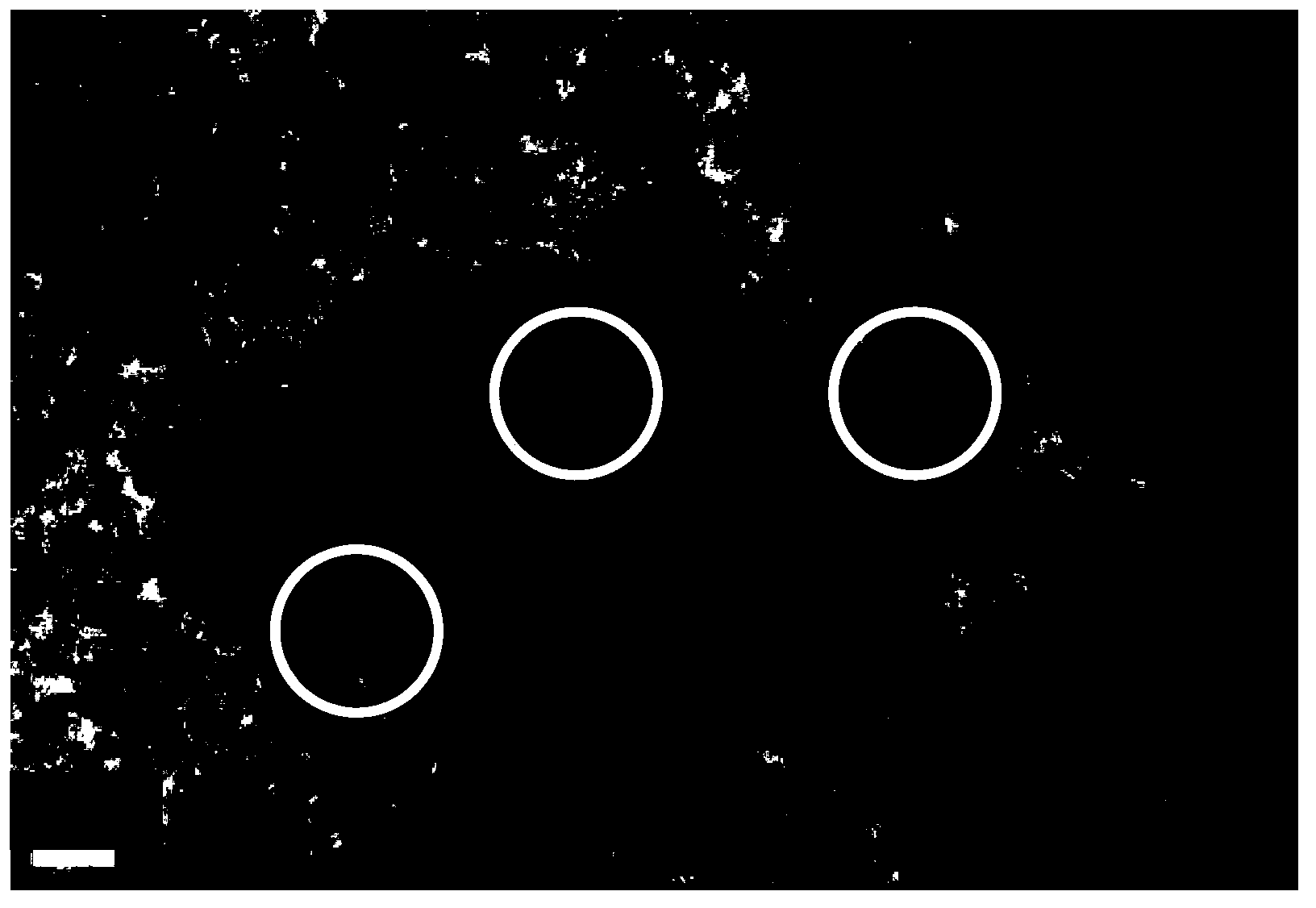

[0061] (1) Weigh 0.0499g of In(NO 3 ) 3 4.5H 2 Dissolve O in 2.4mL deionized water to make a solution, and weigh 3g of γ-Al at the same time 2 o 3 Add the above solution. Then put it into an ultrasonic instrument, adjust the water temperature to 40°C, and ultrasonically vibrate for 1 hour. The sonicated samples were dried in an oven at 150°C for 2 hours. Finally, the dried sample was placed in a muffle furnace at a rate of 10 °C / min to 700 °C, baked in air for 1 hour, and cooled to room temperature.

[0062] (2) Dissolve 2.4mL of 0.01g / mL chloroplatinic acid solution in the calcined sample, put it into an ultrasonic instrument, adjust the water temperature to 40°C, and oscillate ultrasonically for 6 hours. The sonicated samples were dried in an oven at 110° C. for 2 hours. Finally, the dried sample was placed in a muffle furnace at a rate of 2°C / min to 500°C, baked in air for 5 hours, and cooled to room temperature.

[0063] Catalyst Cat#2 was produced.

[0064] Plati...

Embodiment 3

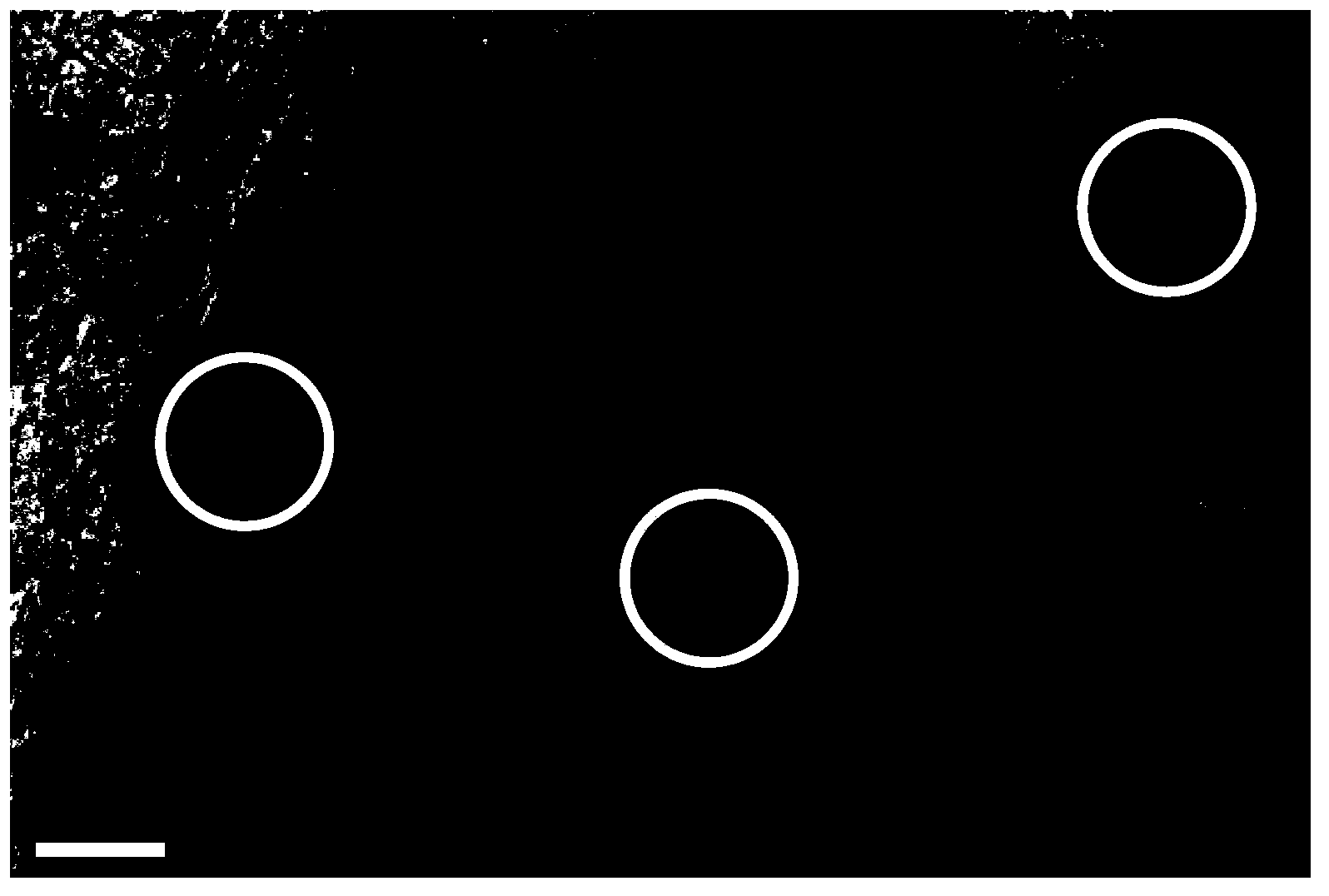

[0072] (1) Weigh 0.0998g of In(NO 3 ) 3 4.5H 2 Dissolve O in 2.4mL deionized water to make a solution, and weigh 3g of γ-Al at the same time 2 o 3 Add the above solution. Then put it into an ultrasonic instrument, adjust the water temperature to 30°C, and ultrasonically vibrate for 6 hours. The sonicated samples were dried in an oven at 110° C. for 2 hours. Finally, the dried sample was placed in a muffle furnace at a rate of 5 °C / min to 500 °C, baked in air for 5 hours, and cooled to room temperature.

[0073] (2) Dissolve 2.4mL of 0.01g / mL chloroplatinic acid solution in the calcined sample, put it into an ultrasonic instrument, adjust the water temperature to 40°C, and oscillate ultrasonically for 1 hour. The sonicated samples were dried in an oven at 100°C for 2 hours. Finally, the dried sample was placed in a muffle furnace at a rate of 2°C / min to 500°C, baked in air for 5 hours, and cooled to room temperature.

[0074] Catalyst Cat#3 was produced.

[0075] Plati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com