Preparation of novel hydrogenation catalyst

A hydrogenation catalyst, a new type of technology, used in the preparation and application of catalytic materials, can solve the problems of harsh reaction conditions, failure to meet market demand, and limit industrial applications, and achieve excellent performance, excellent hydrogenation effect, and simple and effective preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

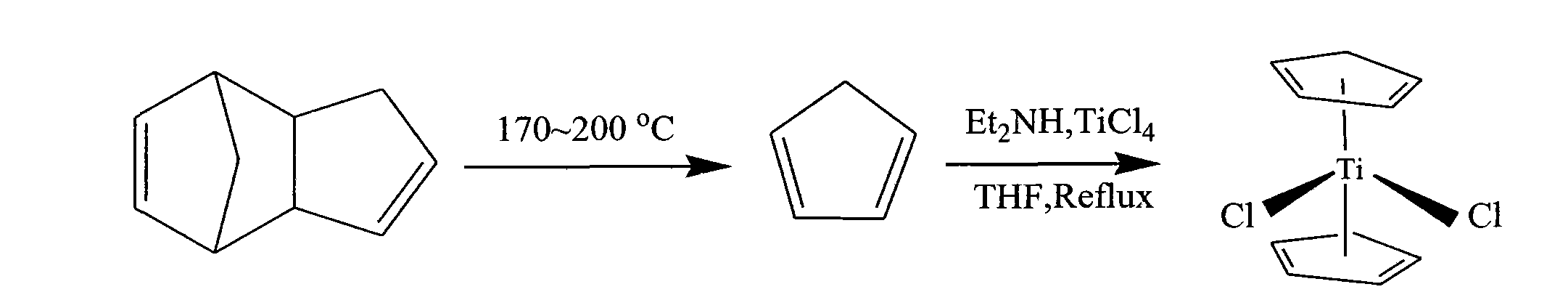

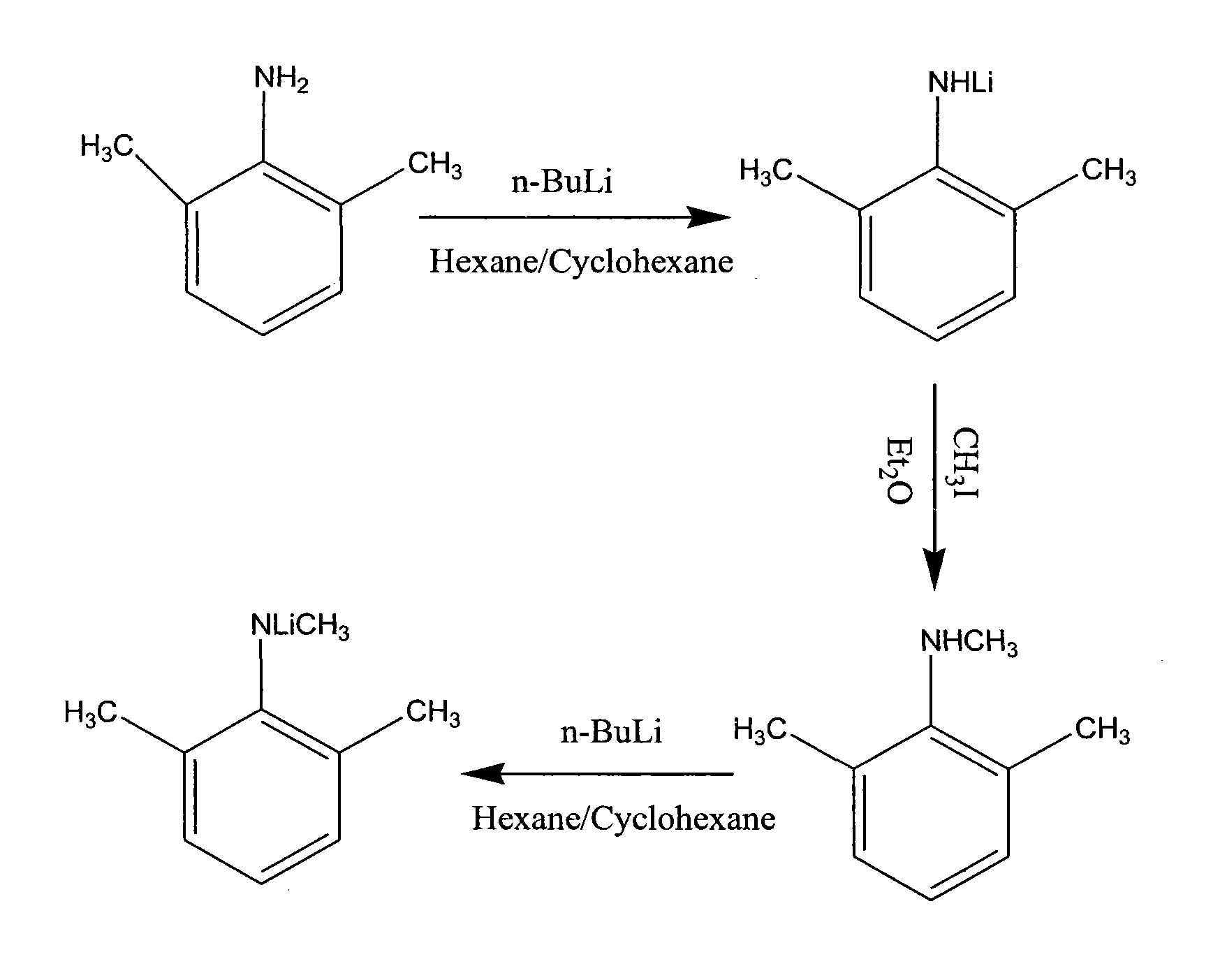

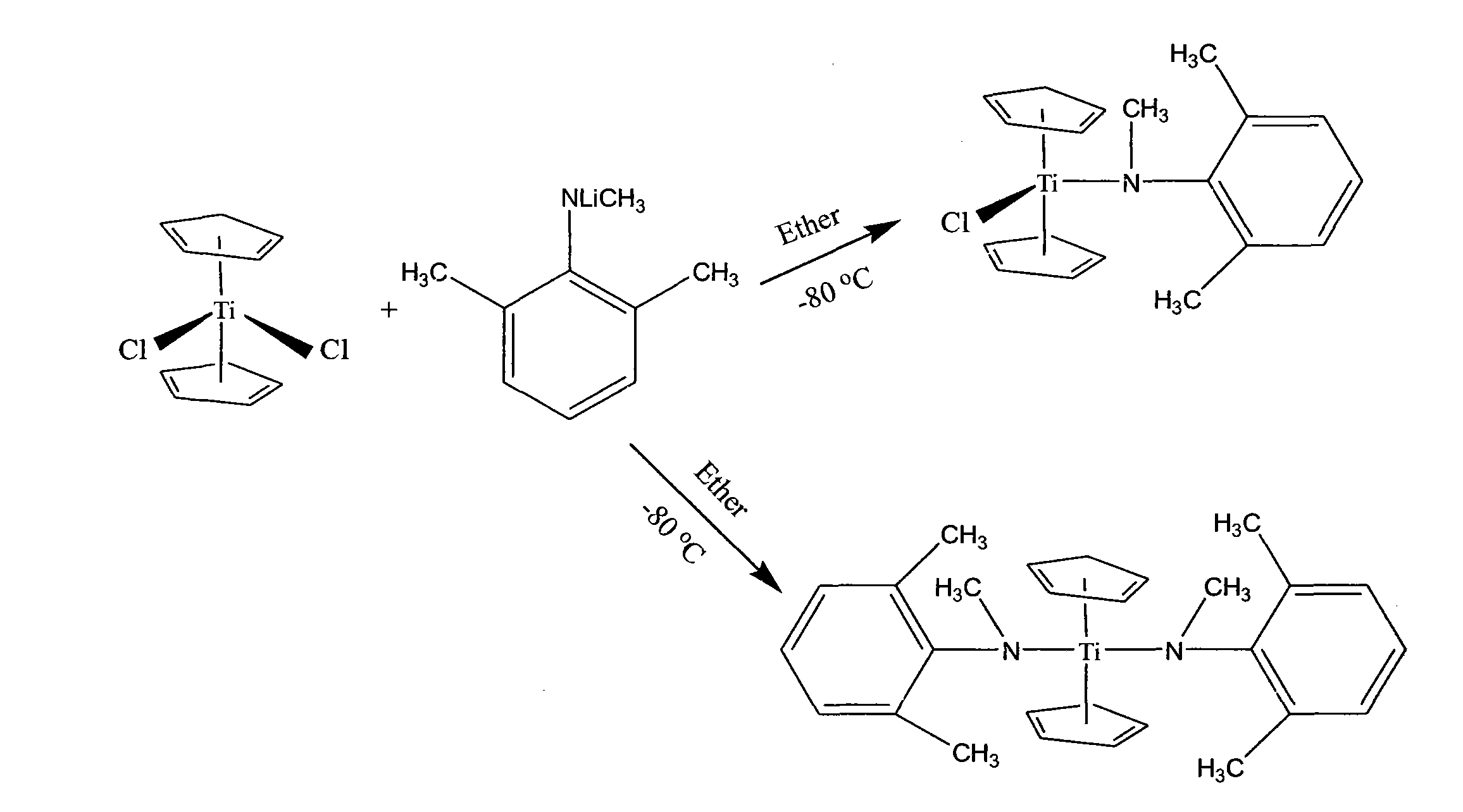

[0032] Step 1, the preparation of titanocene dichloride:

[0033] N 2 Under protection, the method of two-stage distillation is adopted, and 25g of dicyclopentadiene is added to the three-necked flask, and the temperature is slowly raised to 190°C at a rate of 5°C / min. In the flask, the temperature of the second stage was raised to 50°C, and the distilled components were collected under ice bath to obtain 17.7g of cyclopentadiene; 5ml of TiCl 4 The solution was added to a three-necked flask in an ice bath, and 70ml of THF was added dropwise to the TiCl with a dropping funnel. 4 During the process, a yellow precipitate was formed, and the precipitate was slowly dissolved by continuing dropwise addition. Add 20ml of anhydrous diethylamine after the dropwise addition and stir for a certain period of time, the solution turns gray-green, then freshly distill 20ml of cyclopentadiene solution, the solution color turns brownish red. The temperature was raised to 60°C, refluxed for ...

Embodiment 2

[0043] Step 1, the preparation of titanocene dichloride:

[0044] N 2 Adopt the method of two-stage distillation under protection, add 30g of dicyclopentadiene into the three-necked flask, slowly raise the temperature to 200°C, the heating rate is 10°C / min, and collect the distillate in the second-stage distillation under normal pressure In the flask, the temperature of the second stage was raised to 70°C, and the distilled components were collected under ice bath to obtain 20 g of cyclopentadiene; 15 ml of TiCl 4 The solution was added to a three-necked flask in an ice bath, and 100ml of THF was added dropwise to TiCl with a dropping funnel. 4 During the process, a yellow precipitate was formed, and the precipitate was slowly dissolved by continuing dropwise addition. Add 50ml of anhydrous diethylamine after the dropwise addition and stir for a certain period of time, the solution turns gray-green, then add 50ml of the cyclopentadiene solution of step (1), and the solution ...

Embodiment 3

[0054] Step 1, the preparation of titanocene dichloride:

[0055] N 2 Adopt the method of two-stage distillation under protection, add 50g of dicyclopentadiene into the three-necked flask, slowly raise the temperature to 220°C, the heating rate is 15°C / min, and collect the distillate in the second-stage distillation under normal pressure In the flask, the temperature of the second stage was raised to 60°C, and the distilled components were collected under ice bath to obtain 35.8g of cyclopentadiene; 20ml of TiCl 4 The solution was added to a three-necked flask in an ice bath, and 80ml of THF was added dropwise to the TiCl with a dropping funnel. 4 During the process, a yellow precipitate was formed, and the precipitate was slowly dissolved by continuing dropwise addition. Add 70ml of anhydrous diethylamine after the dropwise addition and stir for a certain period of time, the solution turns gray-green, then add 70ml of the cyclopentadiene solution of step (1), and the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com