Preparation of an explosive and its texture interface explosive compression method

A technology of explosives and textures, which is applied in the field of energetic materials and metal composites, can solve the problems of low energy utilization rate, overmelted brittle intermetallic compounds, and uneven charge thickness, so as to improve energy utilization efficiency and increase the amount of explosives per unit area. The effect of large, small amount of explosive per unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this experiment, a "skin" explosive based on RDX was prepared. First, passivate black Sogeum. Take 30g of Roxygen and paraffin according to the ratio of 95:5 and heat it at a constant temperature of 90°C for half an hour, then air-cool it in dry air, and passivate Roxygen from time to time until the temperature of Roxygen reaches normal temperature. Then 36g of nitromethane and nitrocellulose were mixed into a solution according to the ratio of 96:4, and then passivated hexogen, plasticizer and a certain amount of plasticizer were added to the nitrocellulose solution and mixed evenly. Finally, the prepared viscoelastic explosive was laid flat on the surface of aluminum foil with a size of 200mm×100mm×0.02mm to ensure that the thickness of the explosive at all positions of the aluminum foil was basically the same, and then placed in the shade for one day.

Embodiment 2

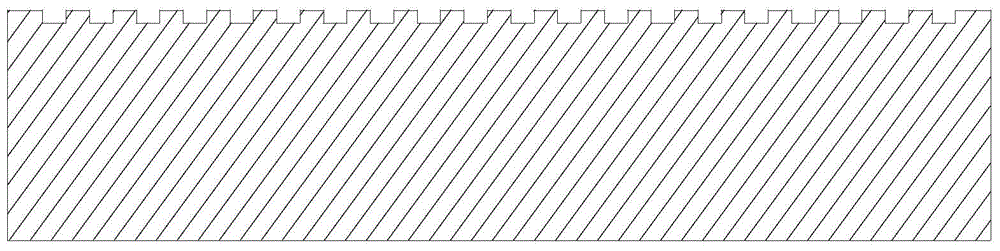

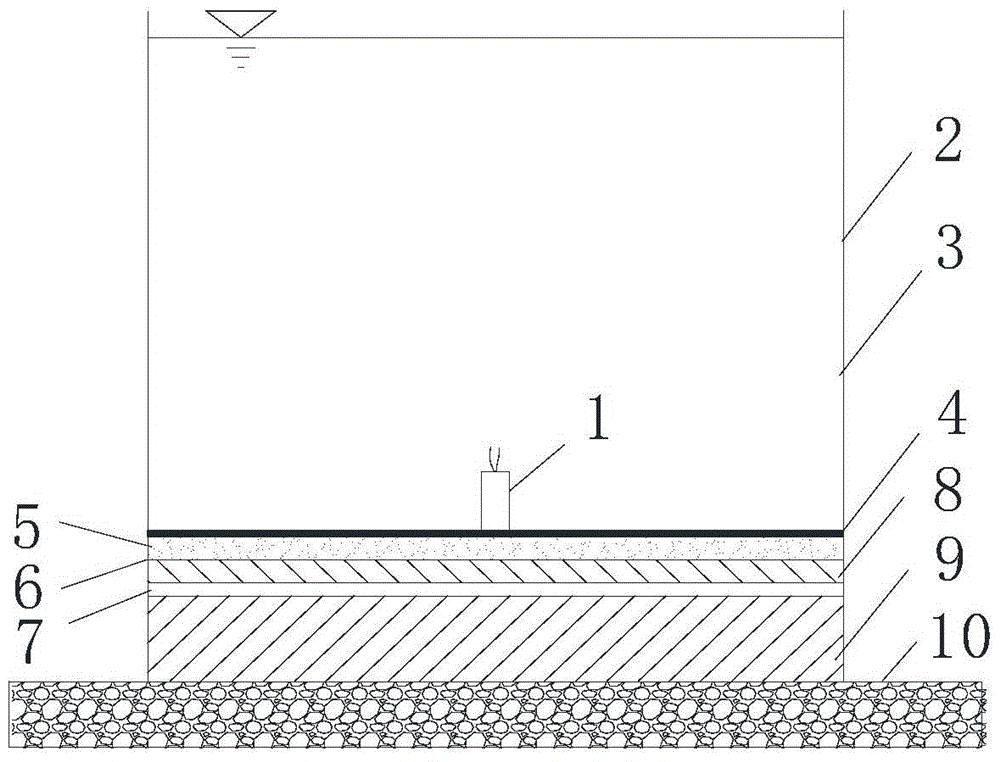

[0046] In this experiment, aluminum alloy plate and Q235 steel plate are selected as the explosion-bonded laminate and substrate respectively. The dimensions of aluminum alloy plate and Q235 steel plate are 200mm×100mm×4mm, 200mm×100mm×18mm, and the substrate surface is 100mm 5×mm×2mm rectangular groove, such as figure 1 Shown. The "skin" explosive is used as the explosive compressed explosive, the film material is aluminum foil, the size is 200mm×100mm×0.05mm, and the mass is 2.7g; the main components of the explosive are hexogen, nitrocellulose, nitromethane, and phthalic acid After the dibutyl ester and nitromethane volatilize, the ratio of RDX to nitrocellulose is 95:5, and the density is 1.5g / cm 3 , The quality is 30g. The detonation point is located at the center of the explosive, and the test device is like figure 2 Shown. The test steps are as follows: (1) After sanding the base and the cover plate to be flat and smooth, place an inverted "V"-shaped gap column 7 with ...

Embodiment 3

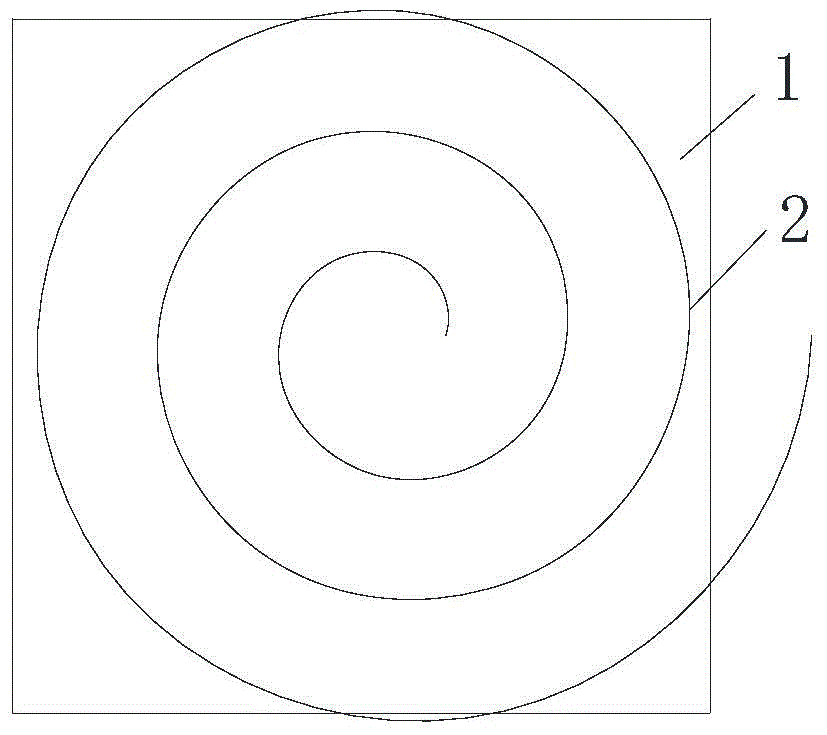

[0048] In this experiment, aluminum plate and Q235 steel plate are selected as the explosion-bonded cover plate and base plate, respectively. The dimensions of the aluminum plate and steel plate are 100mm×100mm×2mm, 100mm×100mm×18mm, and the surface of Q235 steel plate is 100mm long every 2.5mm. A rectangular groove with a width of 2.5mm and a height of 1mm, such as figure 1 Shown. Explosive compressed explosives use explosive fibers. The explosive fibers are linear, aluminum shell, diameter 3mm, the innermost circle diameter is 150mm, the average distance between each circle is 150mm, and the total length of the explosive fiber is 800mm. The explosive fiber is wound into a "mosquito coil" shape before charging. Such as image 3 As shown, the explosive fiber is placed on the surface of the aluminum plate, such as Figure 5 Shown. The experiment adopts the parallel installation method for explosive pressing. The experiment steps: (1) After sanding the base and the cover plate to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com