Processing apparatus and method for wastewater containing organic pollutants

A technology for organic pollutants and treatment devices, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. effect of mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

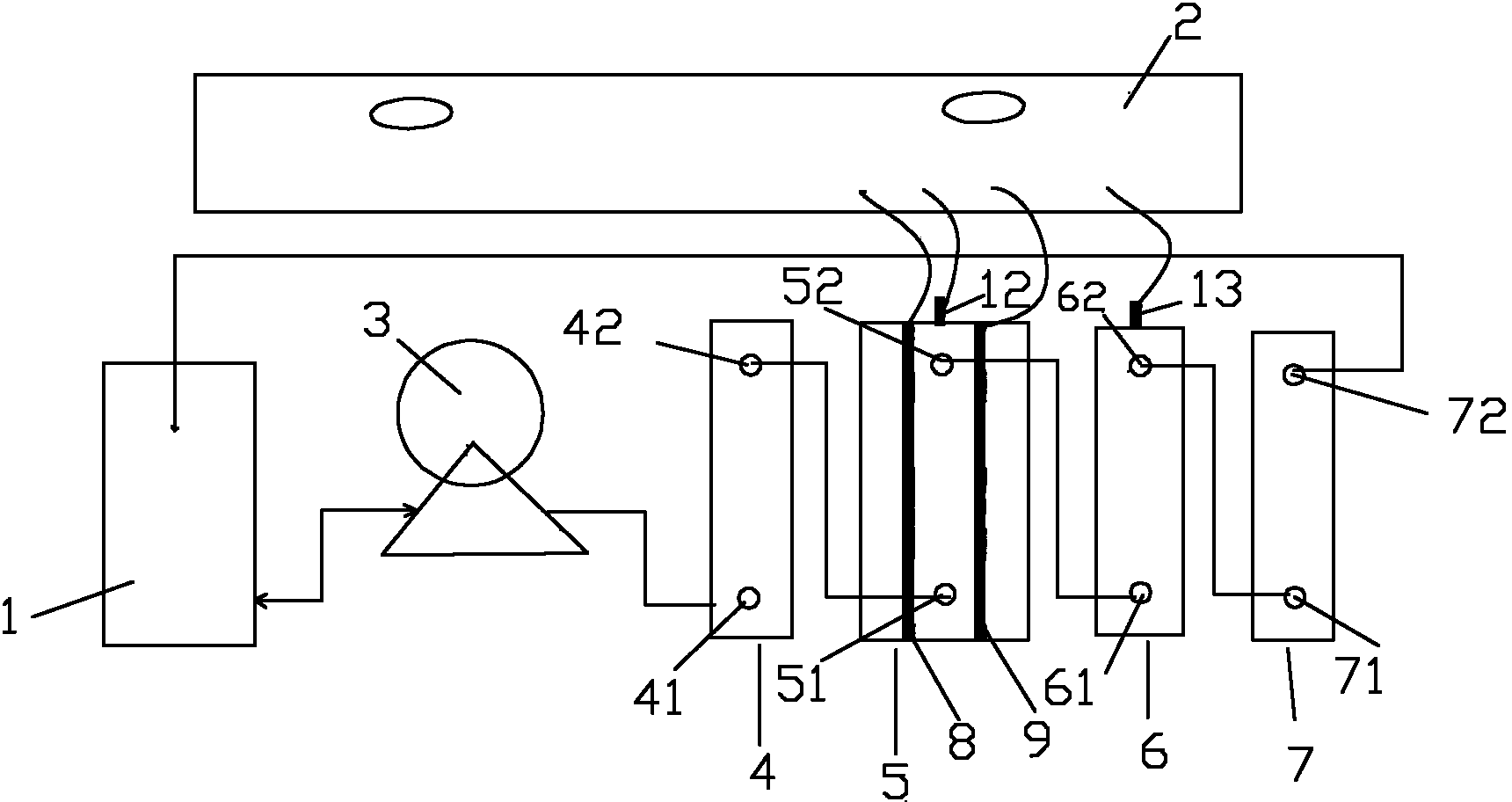

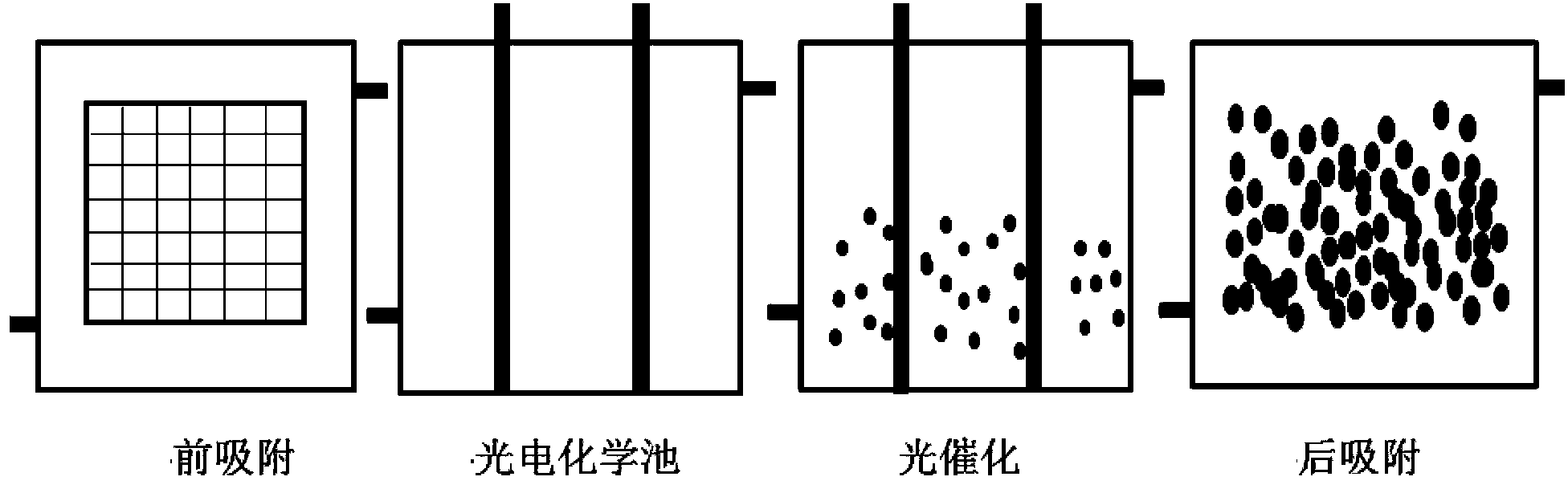

[0035]As shown in the figure, the wastewater treatment device of the present invention includes a liquid storage tank 1, a circulating flow pump 3, a front adsorption pool 4, a photoelectrochemical pool 5, a photocatalytic pool 6 and a rear adsorption pool 7; Adsorption materials are placed in the adsorption pool 7; a cathode 8 and an anode 9 are arranged in the photoelectrochemical cell 5, and a first light source 12 is arranged directly above the cathode and anode; the photocatalytic cell 6 has a built-in photocatalyst The porous material is provided with a second light source 13 right above it; the liquid storage tank 1, circulating flow pump 3, front adsorption cell 4, photoelectrochemical cell 5, photocatalytic cell 6 and rear adsorption cell 7 are sequentially connected through pipelines.

[0036] The front adsorption pool 4 is provided with a water inlet 41 and a water outlet 42, the photoelectrochemical cell 5 is provided with a water inlet 51 and a water outlet 52, the...

Embodiment 2

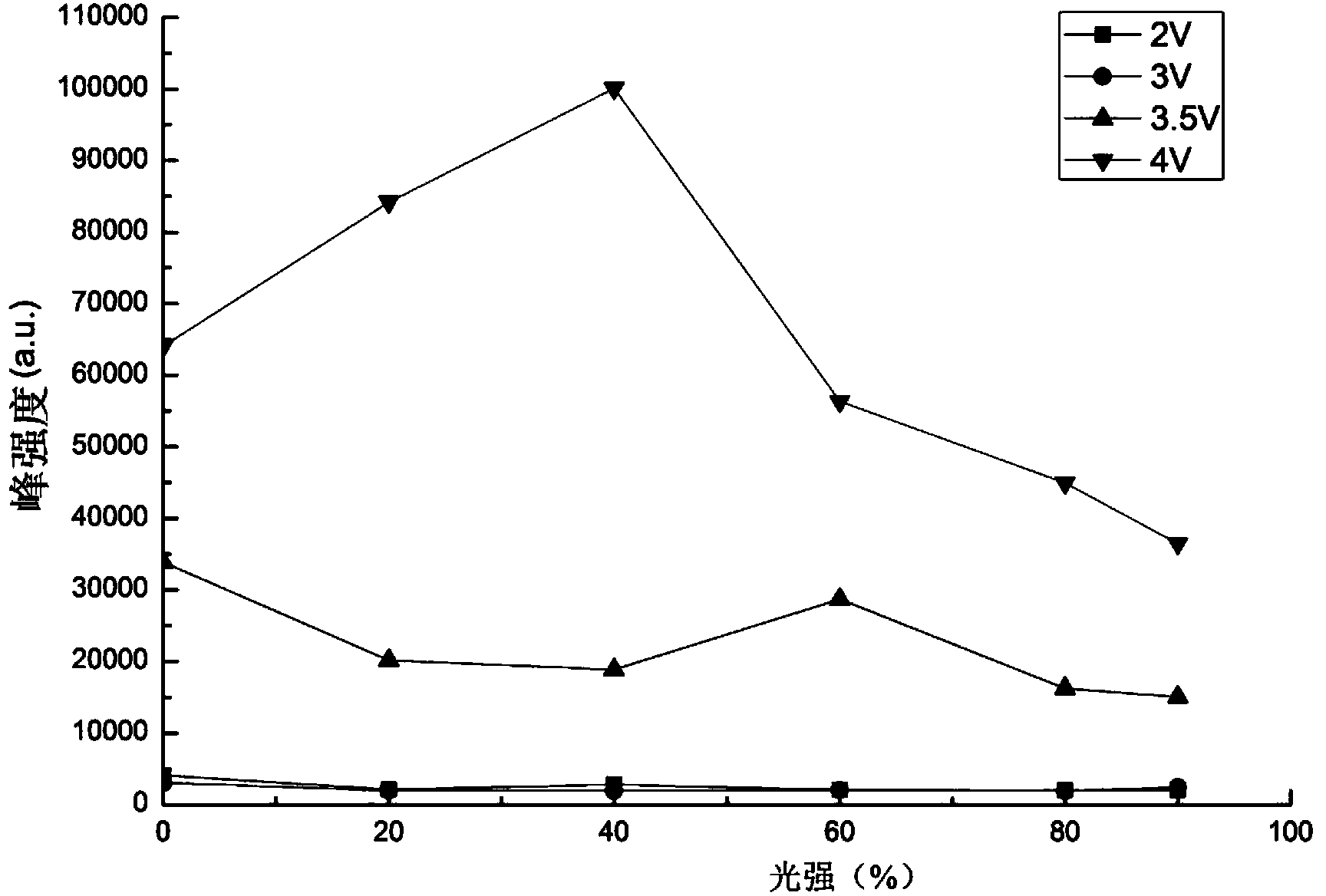

[0041] In the experiment with 0.2M Na 2 SO 4 As the electrolyte, Ag / AgCl is the reference electrode, the potentiostat provides a constant voltage, BDD and Pt are used as the cathode and anode respectively, and the electrode area is 5cm 2 , fixed the pole spacing of 2.5cm, and measured the Na produced when sodium sulfate electrolyte was added to react for 40min under a certain voltage and light intensity. 2 S 2 o 8 The amount of active substance, such as Figure 4 . Then measure the degradation effect to Orange II under the same conditions, such as Figure 5 . Select the condition with the best effect of 4V and 40% of the maximum light intensity, change the pole spacing, and measure the Na produced by the sodium sulfate electrolyte. 2 S 2 o 8 The amount of active substance, such as Figure 6 , under the same conditions, the degradation effect on Orange II was measured, such as Figure 7 , get the best pole spacing 2.5cm. Na in the experiment 2 S 2 o 8 And the amo...

Embodiment 3

[0043] Porous ceramics are installed in the front adsorption cell 4, BDD cathode and anode electrode sheets and two 254nm ultraviolet lamps are installed in the photoelectrochemical cell 5, and TiO2 is filled in the photocatalytic cell 6 2 Molecular sieve and 2 254nm ultraviolet lamps, granular activated carbon is housed in the rear adsorption pool 7, fills up the reaction pool.

[0044] Using the device, 1L of Orange II dye wastewater containing 50ppm was degraded. The supporting electrolyte is 0.2mol / L Na 2 SO 4 Solution, under the condition of a constant voltage of 12V, the electrolyte solution was first passed through for 15 minutes for preheating treatment, and then the solution containing 0.2mol / L Na 2 SO 4 For the 50ppm Orange II dye wastewater in the electrolyte solution, the decolorization rate can reach 92.3% in one cycle, and 100% in two cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com