Out-plane piezoelectric type hemispheric micro-gyroscope and preparation method thereof

A micro-gyroscope and hemispherical technology, applied in gyroscope/steering sensing equipment, gyro effect for speed measurement, piezoelectric device/electrostrictive device, etc., can solve the problem of difficult to realize highly symmetrical electrode processing and interference micro-gyroscope control and detection, doping technology and limited production accuracy, to achieve the effect of mass production, large effective vibration displacement, and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as figure 2 As shown, the present embodiment provides an out-of-plane piezoelectric hemispherical micro-gyroscope, including:

[0039] A monocrystalline silicon substrate 1 with a hemispherical groove;

[0040] A miniature hemispherical harmonic oscillator 2;

[0041] a cylindrical support column 3;

[0042] a common electrode 4;

[0043] Eight uniformly distributed thin-film piezoelectric bodies 5;

[0044] Eight evenly distributed signal electrodes 6;

[0045]Wherein: the surface provided with the hemispherical groove is the upper surface of the single crystal silicon substrate 1, and the opposite surface is the lower surface; the upper end of the cylindrical support column 3 is connected to the micro-hemispherical resonator 2, and the lower end is connected to the micro-spherical resonator 2. The single crystal silicon substrate 1 is connected; the cylindrical support column 3 and the miniature hemispherical resonator 2 are located in the hemispherical gro...

Embodiment 2

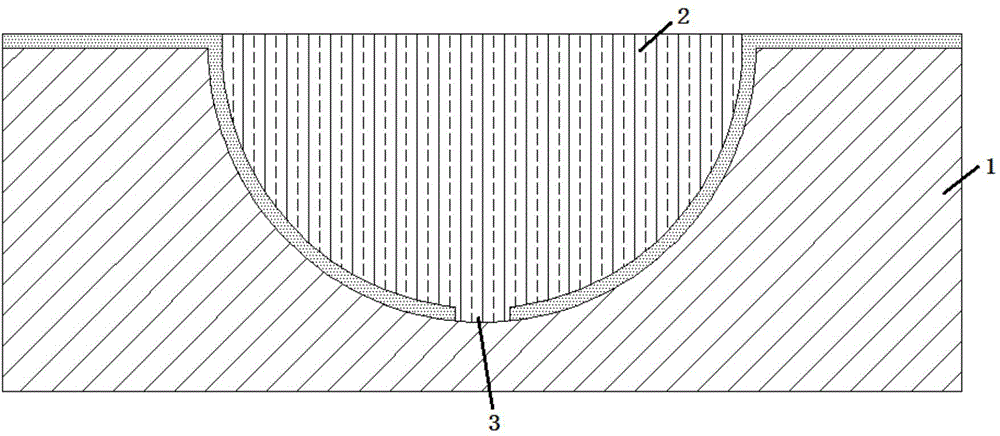

[0057] Such as Figure 1(a)-Figure 1(f) As shown, the present embodiment provides a method for preparing an out-of-plane piezoelectric hemispherical micro-gyroscope, including the following steps:

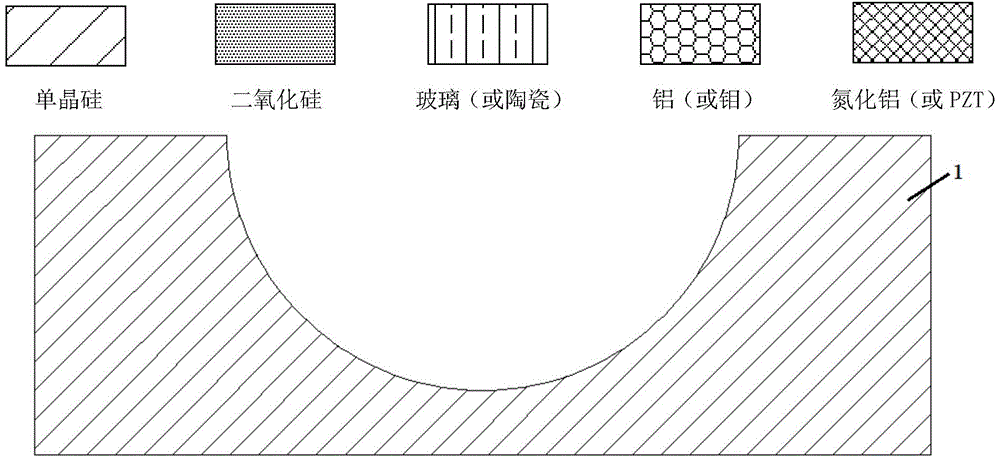

[0058] The first step, as shown in FIG. 1(a), is to clean the single crystal silicon substrate 1, grow a silicon nitride layer, and perform steps such as coating, photolithography, development, RIE etching, and degumming on the silicon nitride layer. A circular opening is opened on the top, and a hemispherical groove with a radius of 350-650 μm is prepared on the single crystal silicon substrate 1 through steps such as HNA etching and hot phosphoric acid etching;

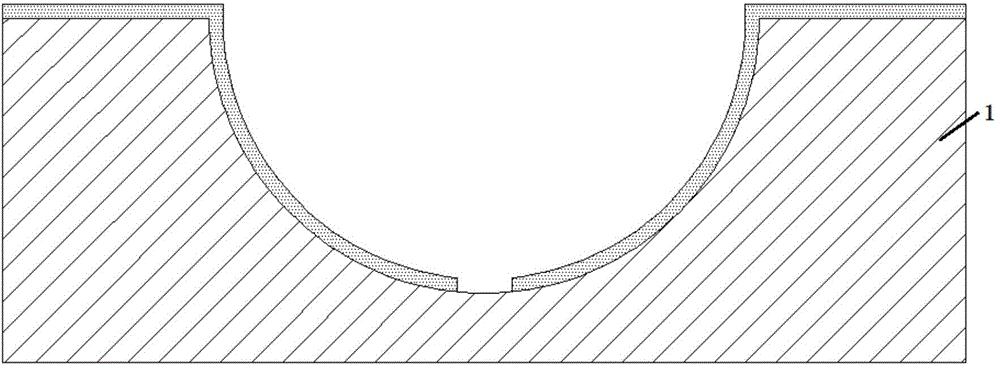

[0059] The second step, as shown in Figure 1(b), is to thermally oxidize and grow a silicon dioxide layer with a thickness of 1-10 μm on the basis of the first step, through the steps of coating, photolithography, development, etching, and degumming. Making a circular opening with a radius of 20-50 μm at the bottom of th...

Embodiment 3

[0066] Basically the same as embodiment 1 and embodiment 2, the difference is:

[0067] Such as image 3 As shown, in this embodiment, the material of the micro-hemispherical resonator 2 and the cylindrical support column 3 is metallic glass or metal, and the micro-hemispherical resonator 2 can be used as the micro-hemispherical resonator 2 and the common electrode at the same time. 4. There is no need to make an additional common electrode 4 , and the thin-film piezoelectric body 5 is evenly distributed on the upper surface of the miniature hemispherical resonator 2 at this time.

[0068] In the preparation method of the gyroscope with this structure, the fourth step is omitted in the preparation method steps of Example 2, that is, the fifth step is based on the third step by sputtering an aluminum nitride film or a PZT film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com