Oxytetracycline wastewater treatment process

A technology for wastewater treatment and oxytetracycline, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply saving, etc. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

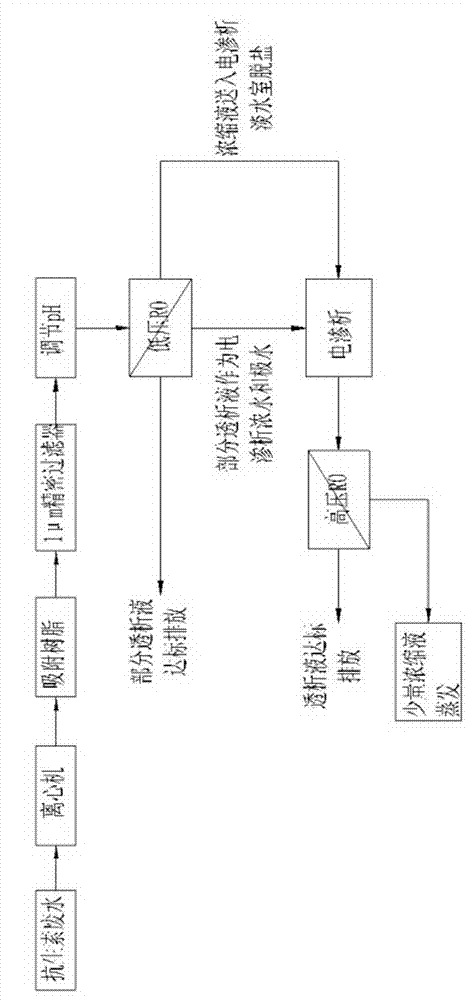

[0036] Example 1: Oxytetracycline wastewater treatment process

[0037] ① Filtrate oxytetracycline wastewater through a centrifuge (three-legged centrifuge, rotating speed 1200 rpm, loading capacity 145kg) to obtain supernatant;

[0038] ②The supernatant is sent to the adsorption resin for adsorption (macroporous adsorption resin XAD-4);

[0039] ③ adjust the pH value of the solution after the adsorption resin is adsorbed to be 6-7;

[0040] ④ Filter with a precision filter with a precision of 1 μm, and the precision filter is stainless steel;

[0041] ⑤ Feed liquid obtained by filtration is sent to ordinary reverse osmosis membrane system for concentration;

[0042] ⑥Due to the high salt content of oxytetracycline wastewater, ordinary reverse osmosis systems need to overcome huge osmotic pressure to concentrate, and the concentration ratio is low, resulting in low recovery rate of the system and excessive residual concentrate, which is difficult to handle. Therefore, thi...

Embodiment 2

[0045] Embodiment 2: electrodialysis experiment

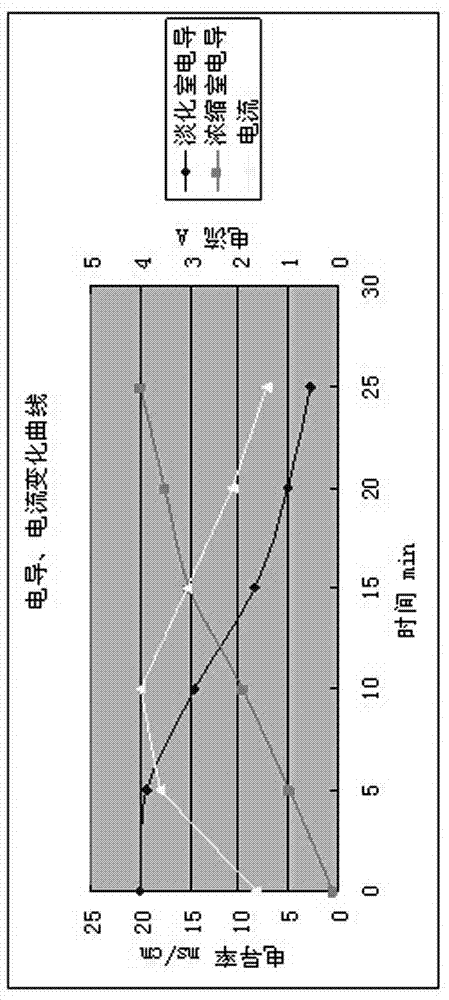

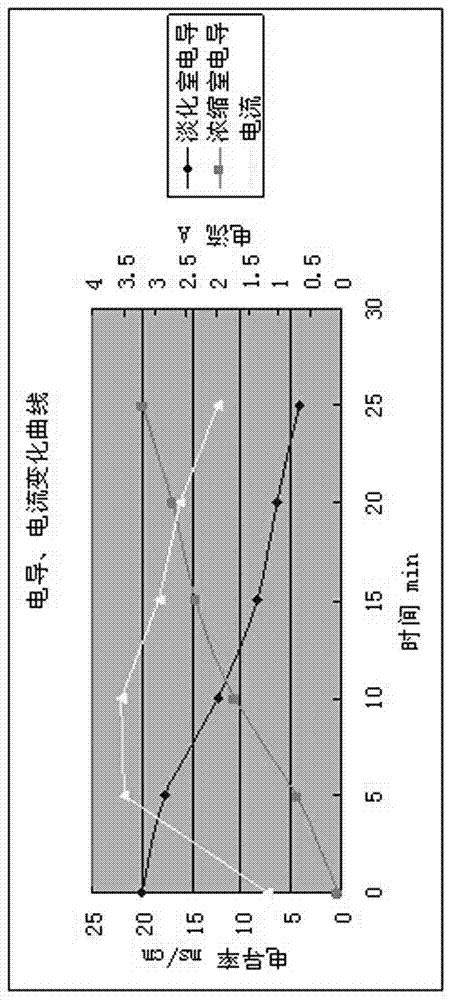

[0046] Electrodialysis is the process of separating different charged solute particles by using the selective permeability of semi-permeable membrane under the action of electric field. However, in the process of electrodialysis desalination, there are often substances other than salt that can also pass through the ion exchange membrane, resulting in a decrease in the yield of materials during the desalination process. In this experiment, by changing the pressure conditions of the concentration chamber and the desalination chamber, the influence of the pressure of the concentration chamber on the recovery rate of the material in the electrodialysis desalination process is studied.

[0047] experimental method:Add the configured soy sauce water with a conductivity of 20 ms / cm into the desalination chamber, and conduct the desalination experiment under the conditions of 0.03 MPa / 0.03 MPa and 0.01 MPa / 0.04 MPa in the desalinat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com