Alkali-soluble resin polymer and preparation method thereof

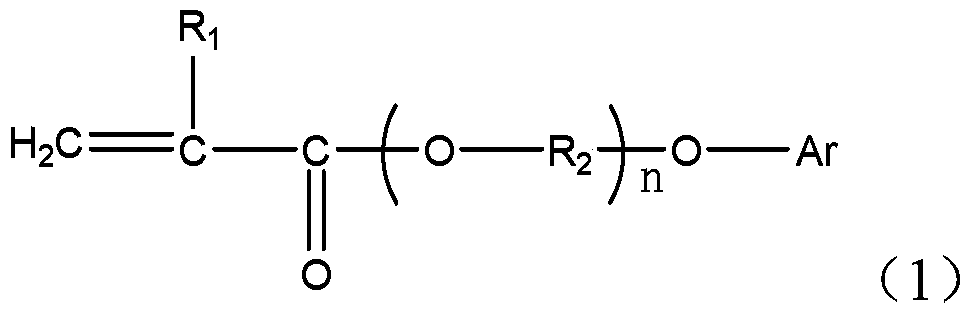

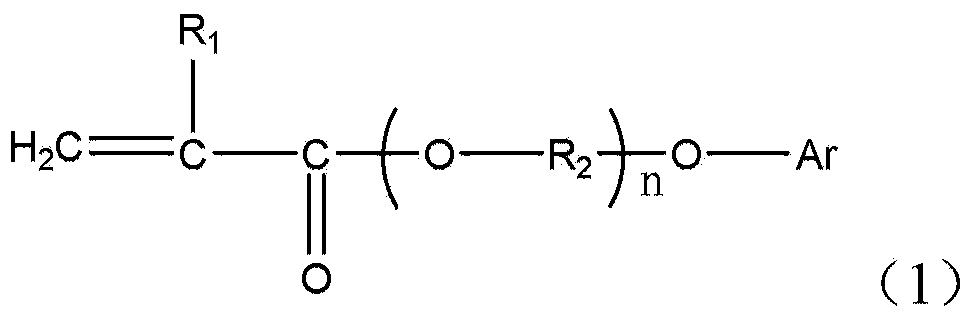

An alkali-soluble resin and polymerizable technology, which can be used in photomechanical equipment, photographic plate-making process of patterned surface, and photosensitive materials used in optomechanical equipment, etc. It can solve the problem of pigment particle aggregation, heat resistance, difficulty, and dispersion aid Increased usage, etc., to achieve the effect of less change in color coordinates, high sensitivity, and excellent developability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] The following examples will further specifically illustrate the embodiment of the preparation of the alkali-soluble resin used in the photosensitive resin composition provided by the present invention. The embodiments are not intended to limit the scope of the present invention, any modifications and changes made by those skilled in the art without departing from the spirit of the present invention all belong to the scope of the present invention. When the chemical reagents used appear for the first time, the model and manufacturer are indicated in the following brackets, and the reagents that appear later are from the same source as when they first appeared.

Synthetic example 1

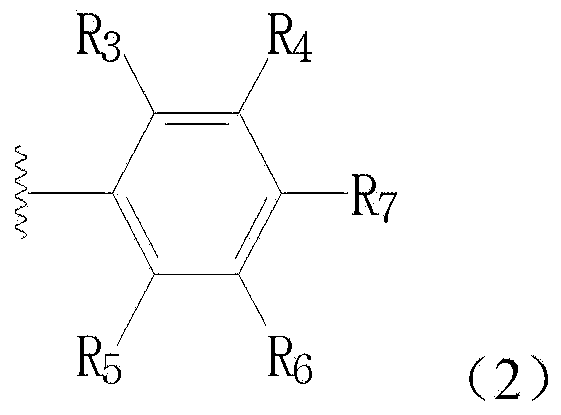

[0073]Add 60g methacrylic acid (Sinopharm Group, chemically pure), 190g phenyl methacrylate (Bailingwei, chemically pure) in a 2L reactor with reflux condensing device, stirring device, temperature control system and constant pressure dropping funnel, The compound of 120g above-mentioned serial number 1 (self-made, adopt COMBI-BLOCKS company to buy 3,5-Diphenylphenol raw material preparation), 50gN-benzylmaleimide (Bailingwei, analytical pure), 720g propylene glycol methyl ether acetate (Tianjin Tai Rong, chemically pure), 5ml molecular weight regulator, the system is heated to 75 ℃, under nitrogen protection and stirring, 80g of azobisisobutyronitrile (Sinopharm Group, chemically pure) will be dissolved with 10g of azobisisobutyronitrile (Sinopharm Group, chemically pure) with a constant pressure dropping funnel Propylene glycol methyl ether acetate solution and 60g of methacrylic acid were added dropwise into the four-necked flask within 2 hours, then stirred and reacted at c...

Synthetic example 2

[0075] Add 60g of methacrylic acid, 190g of phenyl methacrylate, and 120g of the compound of the above serial number 2 (self-made, purchased from eBUYCHEM) 4-n-Propyl-1-naphthol raw material preparation), 50gN-benzylmaleimide, 720g propylene glycol methyl ether acetate; 5ml molecular weight modifier, system is heated to 75 ℃, under nitrogen protection and stirring situation, use A constant-pressure dropping funnel was used to drop 80 g of propylene glycol methyl ether acetate solution and 60 g of methacrylic acid dissolved in 10 g of azobisisobutyronitrile into the four-necked bottle within 2 hours, then stir and react at a constant temperature for 5 hours, and then lower the temperature to At room temperature, the polymer product was taken out from the four-necked bottle, and the solvent was removed to obtain alkali-soluble resin A2. The weight average molecular weight of the polymer measured by GPC was 21050, the molecular weight distribution was 2.10, and the acid value was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com