A kind of organic attapulgite modified water-based laminating adhesive and preparation method thereof

A technology of water-based laminating adhesive and attapulgite, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of low adhesion, poor heat resistance, etc., and achieve cohesion Large, improved dispersibility, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

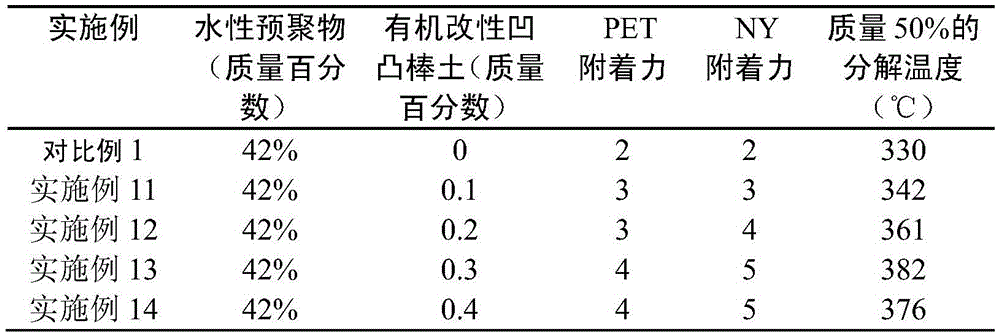

Examples

Embodiment 1

[0033] A water-based laminating adhesive modified by organic attapulgite, comprising 20% polymer polyol, 1% organically modified attapulgite, 20% polyisocyanate compound, and 9% chain extender by mass percentage , 5% neutralizer and 45% deionized water.

[0034] The preparation method of the water-based film-coating glue modified by the above-mentioned organic attapulgite comprises the following steps:

[0035] 1) Mix and stir the original soil with a particle size of 20-40nm and a length of 1-2m and one-dimensional fibrous crystals with double distilled water, then settle, take the upper suspension, filter it with suction, and dry it to obtain purified attapulgite Add the purified attapulgite to hydrochloric acid with a concentration of 2mol / L, and the volume ratio of the purified attapulgite to hydrochloric acid is 1:10, heat to reflux for 8h, and centrifuge after cooling, rinse the resulting solid with distilled water until neutral, vacuum Dried to obtain acidified attap...

Embodiment 2

[0039]A water-based laminating adhesive modified by organic attapulgite, comprising 23% polymer polyol, 0.1% organically modified attapulgite, 18.9% polyisocyanate compound, and 6% chain extender by mass percentage , 2% neutralizer and 50% deionized water.

[0040] The preparation method of the water-based film-coating glue modified by the above-mentioned organic attapulgite comprises the following steps:

[0041] 1) Mix and stir the original soil with a particle size of 20-40nm and a length of 1-2m and one-dimensional fibrous crystals with double distilled water, then settle, take the upper suspension, filter it with suction, and dry it to obtain purified attapulgite Add the purified attapulgite to sulfuric acid with a concentration of 3mol / L, and the volume ratio of the purified attapulgite to hydrochloric acid is 1:10, heat to reflux for 6h, and centrifuge after cooling, rinse the obtained solid with distilled water until neutral, vacuum Dried to obtain acidified attapulgi...

Embodiment 3

[0045] A water-based laminating adhesive modified by organic attapulgite, comprising 14% polymer polyol, 2% organically modified attapulgite, 15% polyisocyanate compound, and 9% chain extender by mass percentage , 5% neutralizer and 55% deionized water.

[0046] The preparation method of the water-based film-coating glue modified by the above-mentioned organic attapulgite comprises the following steps:

[0047] 1) Mix and stir the original soil with a particle size of 20-40nm and a length of 1-2m and one-dimensional fibrous crystals with double distilled water, then settle, take the upper suspension, filter it with suction, and dry it to obtain purified attapulgite Add the purified attapulgite to nitric acid with a concentration of 4mol / L, and the volume ratio of the purified attapulgite to hydrochloric acid is 1:10, heat and reflux for 7h, and centrifuge after cooling, rinse the resulting solid with distilled water until neutral, vacuum Dried to obtain acidified attapulgite;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com