Exopolysaccharide generated by pseudomonas, culture method and application

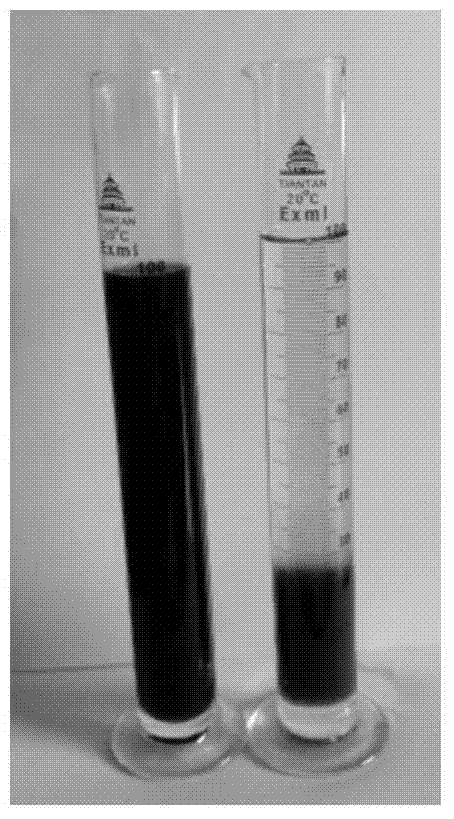

A technology of pseudomonas and extracellular polysaccharide, applied in the field of microorganisms, can solve problems such as the inability to meet the needs of industrial production, and achieve the effects of high suspended particle flocculation activity, good water solubility and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The strain Pseudomonas (Pseudomonas sp.) QL212 provided by the present invention is collected soil samples from the moist open space near the Shaw Science and Technology Building of Jinan University, and the bacterial strain is separated by plate marking method and aniline blue specific staining method. After identification, it has the ability to produce The performance of polysaccharide flocculant.

[0041] The exopolysaccharide strain is a kind of Pseudomonas, and its 16S rDNA sequencing result is shown in SEQ ID NO.1. The number of bases obtained by sequencing is 1209 bp.

[0042] The bacterial strain provided by the invention is cultivated on a solid medium containing 1% sucrose, 0.5% yeast powder and 1.6% agar at 30 DEG C for 24 hours, and after the colony edge is smooth and orderly, the surface is moist, milky white and opaque.

[0043] The above-mentioned Pseudomonas sp. QL212 was deposited on September 12, 2014 in the General Microbiology Center of the China Co...

Embodiment 2

[0045] The cultivation method of above-mentioned pseudomonas (Pseudomonas sp.) QL212, the steps are as follows:

[0046] (1) Inoculate Pseudomonas sp. QL212 on a solid slant medium, activate and culture at 30°C for 24 hours to obtain activated cells;

[0047] (2) Inoculate the activated thalli prepared in step (1) in the seed culture medium, and cultivate at 30° C. and 200 rpm for 20 to 28 hours to obtain the seed liquid;

[0048] (3) Inoculate the seed solution prepared in step (2) into the fermentation medium at a ratio of 10% by volume, and ferment for 6 days at 30° C. and 200 rpm to obtain the fermentation solution;

[0049]The solid slant culture medium in the described step (1) has the following components, all in percent by weight:

[0050] 1% sucrose, 0.5% yeast powder, 1.6% agar, the rest water, pH 7.0;

[0051] Seed culture medium in the described step (2), every liter of components is as follows:

[0052] Sucrose 10g, yeast powder 5g, CaCO 3 1g, dilute to 1L wi...

Embodiment 3

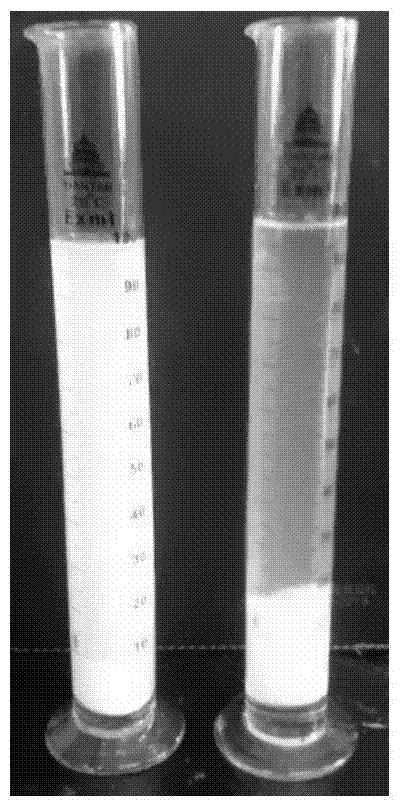

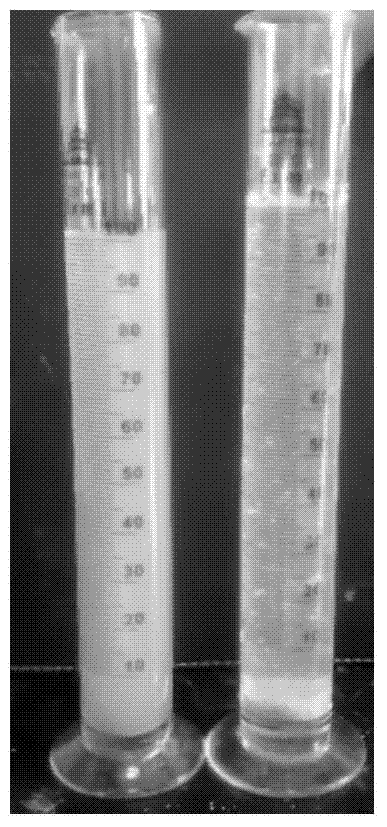

[0056] Get the fermented liquid prepared in Example 2, freeze and centrifuge at 8000rpm for 20min, take the supernatant, add 3 times the volume of absolute ethanol, stir evenly, let stand overnight, collect the precipitate, and wash the precipitate with 80% ethanol by volume percentage , dried at 60°C to constant weight to prepare microbial exopolysaccharide flocculant.

[0057] After testing, 5.92 g of microbial exopolysaccharide flocculant (dry weight) can be obtained per liter of fermentation broth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com