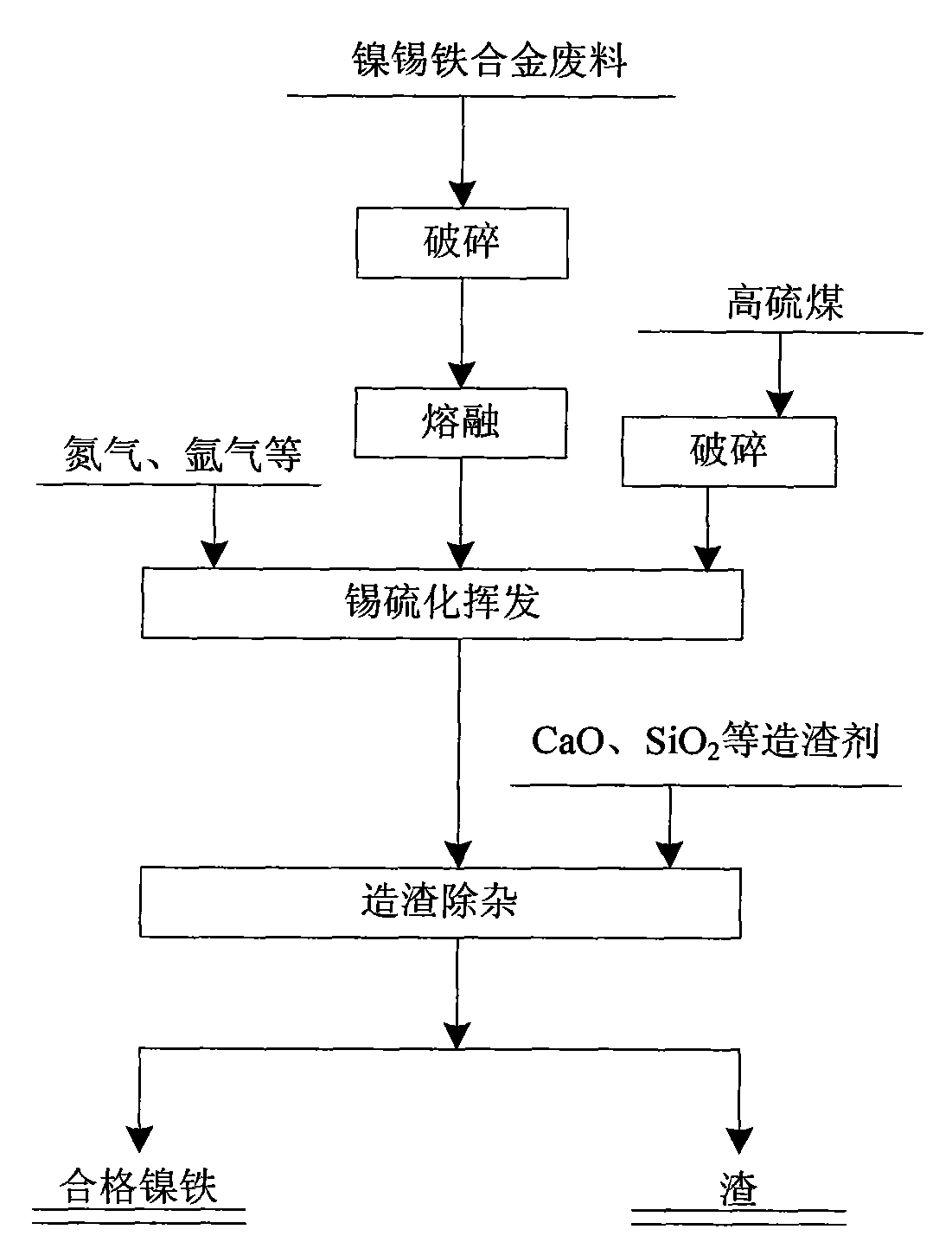

Method for Ni-Fe alloy production and Sn recovery from Ni-Sn ferroalloy scrap by high-sulfur coal sulfuration volatilization and oxidation slagging

A technology of nickel-iron alloy and high-sulfur coal, which is applied in the field of comprehensive utilization of secondary resources, can solve the problems of low utilization rate and poor economic performance, and achieve the effects of low production cost, simple operation and low furnace maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Nickel-tin-iron alloy waste (the main chemical composition is (unit: mass fraction): TFe=31.39, Ni=50.24, Sn=18.37) 5t was crushed to a certain degree and then transferred to the intermediate frequency furnace. The intermediate frequency furnace is heated to 1400°C and when the material is in a molten state, the nitrogen spray gun is deep into the molten pool to stir the reaction system. Mass fraction): fixed carbon = 76.56, ash = 15.39, volatile matter = 4.78, S = 3.27) crushed to a particle size of 0.2-0.4mm, and sprayed into the molten pool by a spray gun to carry out the volatilization and volatilization reaction of tin in the material. As the reaction progresses, the position of the nitrogen spray gun is raised intermittently to achieve the best stirring effect on the molten pool. The nitrogen injection pressure is maintained at 0.4-0.8MPa, and the furnace temperature is controlled at 1450-1500°C. After the vulcanization reaction is completed (the holding time is 6...

Embodiment 2

[0031] Nickel-tin-iron alloy waste (the main chemical composition is (unit: mass fraction): TFe=32.08, Ni=50.37, Sn=17.55) 5t is transferred to the intermediate frequency furnace after crushing to a certain degree. The intermediate frequency furnace is heated to 1400°C and when the material is in a molten state, the nitrogen spray gun is inserted into the molten pool to stir the reaction system. After the furnace is heated to 1500°C and kept for 20 minutes, the high-sulfur coal (its main chemical composition is Mass fraction): fixed carbon = 76.96, ash = 15.69, volatile matter = 5.28, S = 4.17) crushed to a particle size of 0.2-0.4mm, and sprayed into the molten pool by a spray gun to carry out the volatilization and volatilization reaction of tin in the material. As the reaction progresses, the position of the nitrogen spray gun is raised intermittently to achieve the best stirring effect on the molten pool. The nitrogen injection pressure is maintained at 0.9-1.1MPa, and the ...

Embodiment 3

[0033] Nickel-tin-iron alloy waste (the main chemical composition is (unit: mass fraction): TFe=28.93, Ni=54.38, Sn=16.69) 3t was crushed to a certain degree and then transferred to the electric furnace. The electric furnace is heated to 1300°C and when the material is in a molten state, the nitrogen spray gun is deep into the molten pool to stir the reaction system. After the furnace is heated to 1400°C and kept for 30min, the high-sulfur coal (its main chemical composition is Score): fixed carbon = 73.28, ash = 17.02, volatile matter = 5.23, S = 4.47) crushed to a particle size of 0.2-0.4mm, and sprayed into the molten pool by a spray gun to carry out the volatilization and volatilization reaction of tin in the material. As the reaction progresses, the position of the nitrogen spray gun is raised intermittently to achieve the best stirring effect on the molten pool. The nitrogen injection pressure is maintained at 0.15-0.3MPa, and the furnace temperature is controlled at 1400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com