Polysilicate iron/cationic starch composite flocculant and preparation method thereof

A technology of cationic starch and composite flocculant, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. Wide range, simple to operate, easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of polyferric silicate / cationic starch composite flocculant, comprising the following steps:

[0035] (1) Neutralization of waste acid: to 1L total iron concentration is 1.5mol / L, and density is 1.8g / mL of titanium dioxide waste acid, add milk of lime, keep stirring, neutralize to pH and be 1.0, obtain mixture;

[0036] (2) suction filtration: the mixture is subjected to suction filtration, and the obtained filtrate is the neutralization waste acid, for subsequent use;

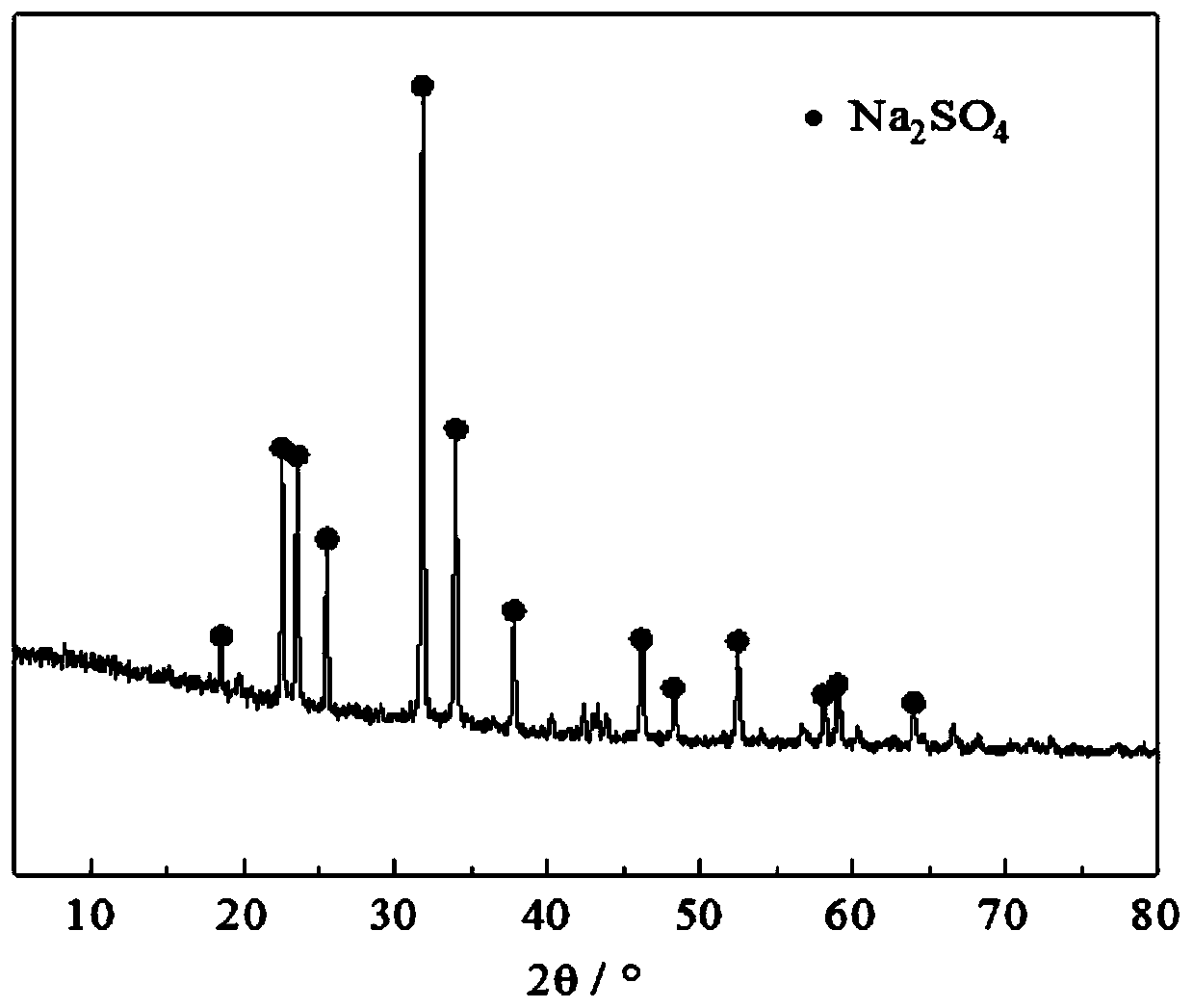

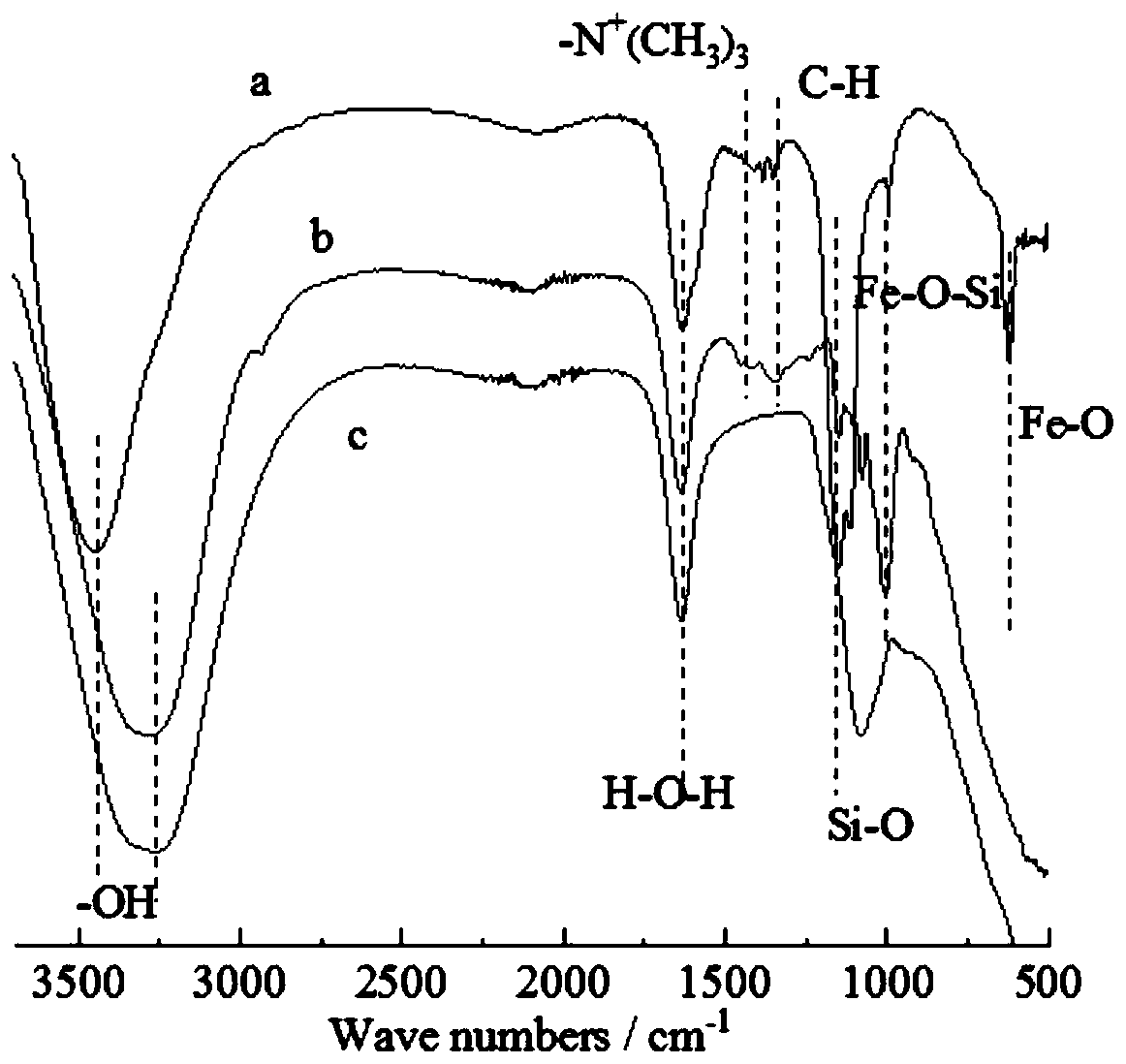

[0037] (3) ripening polymerization: add the sodium silicate solution of 0.1L 3.75mol / L in the neutralized waste acid (the mol ratio of the silicon in the sodium silicate solution and the iron in the titanium dioxide waste acid is 1:4), stir Evenly, then add 5mL 30% hydrogen peroxide to oxidize the ferrous iron in the solution to ferric iron, then add sodium hydroxide to adjust the pH of the solution to be 3.0, then add 8.4g cationic starch (iron and cationic starch in the titanium d...

Embodiment 2

[0039] A preparation method of polyferric silicate / cationic starch composite flocculant, comprising the following steps:

[0040] (1) Neutralization of waste acid: to 1L total iron concentration is 1.7mol / L, and density is 1.8g / mL of titanium dioxide waste acid, adding lime milk, stirring constantly, and neutralization to pH is 1.2, to obtain mixture;

[0041] (2) suction filtration: the mixture is subjected to suction filtration, and the obtained filtrate is the neutralization waste acid, for subsequent use;

[0042] (3) ripening polymerization: add the sodium silicate solution of 0.1L 3.75mol / L in the neutralized waste acid (the mol ratio of the silicon in the sodium silicate solution and the iron in the titanium dioxide waste acid is 1:4), stir Evenly, then add 6mL 30% hydrogen peroxide to oxidize the ferrous iron in the solution to ferric iron, then add sodium hydroxide to adjust the pH of the solution to be 2.8, then add 11.2g of cationic starch (iron and cationic starch ...

Embodiment 3

[0044] A preparation method of polyferric silicate / cationic starch composite flocculant, comprising the following steps:

[0045] (1) Neutralization of waste acid: to 1L total iron concentration is 2.0mol / L, and density is 1.9g / mL of titanium dioxide waste acid, add milk of lime, keep stirring, neutralize to pH 1.5, obtain mixture;

[0046] (2) suction filtration: the mixture is subjected to suction filtration, and the obtained filtrate is the neutralization waste acid, for subsequent use;

[0047] (3) ripening polymerization: add the sodium silicate solution of 0.1L 5mol / L in the neutralized waste acid (the mol ratio of silicon in the sodium silicate solution and the iron in the titanium dioxide waste acid is 1:3), stir evenly , then add 6mL 30% hydrogen peroxide to oxidize the ferrous iron in the solution to ferric iron, then add sodium hydroxide to adjust the pH of the solution to be 2.6, then add 5.6g of cationic starch (the difference between iron and cationic starch in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com