High density ordered graphene with ion spacer layer and its preparation method and application

A graphene and high-density technology, applied in electrical components, electrolytic capacitors, capacitors, etc., can solve the problems of low specific capacitance per unit volume and low packing density, achieve huge specific capacitance per unit volume, large pseudocapacitive current, and increase specific capacitance The effect of capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

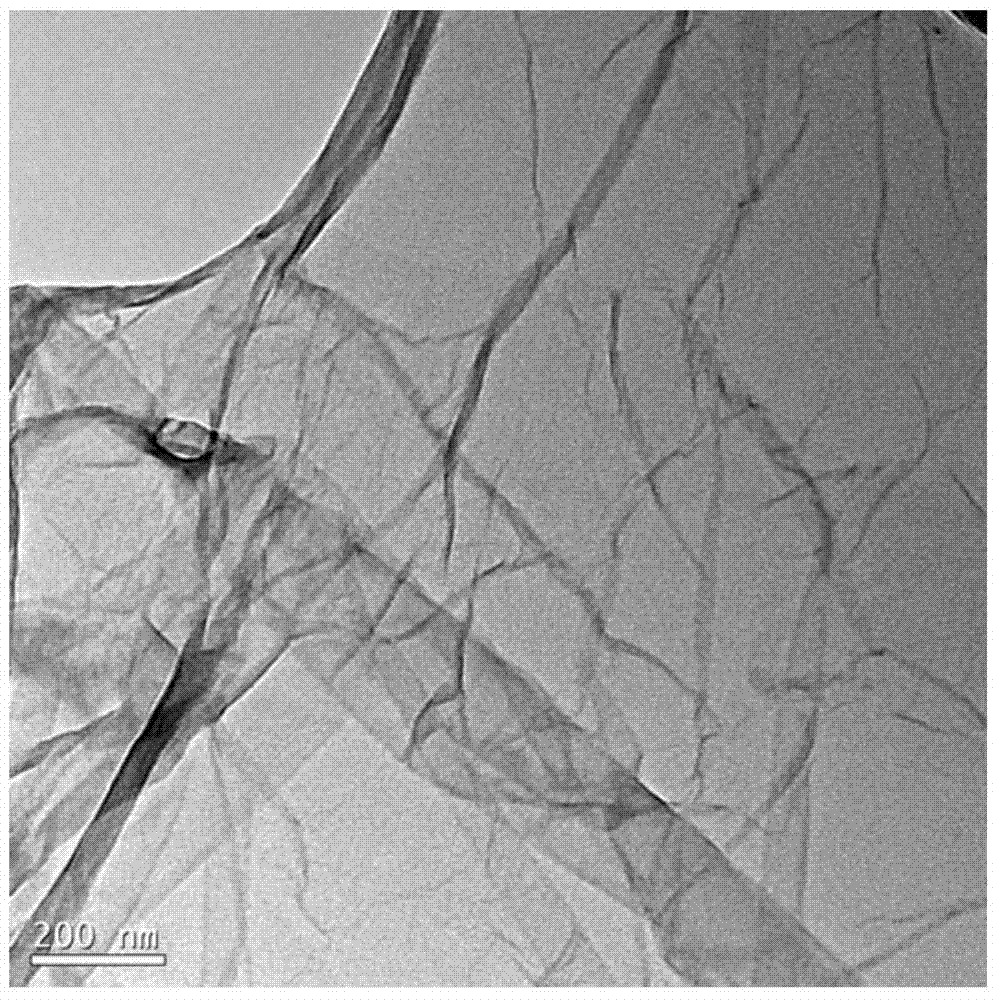

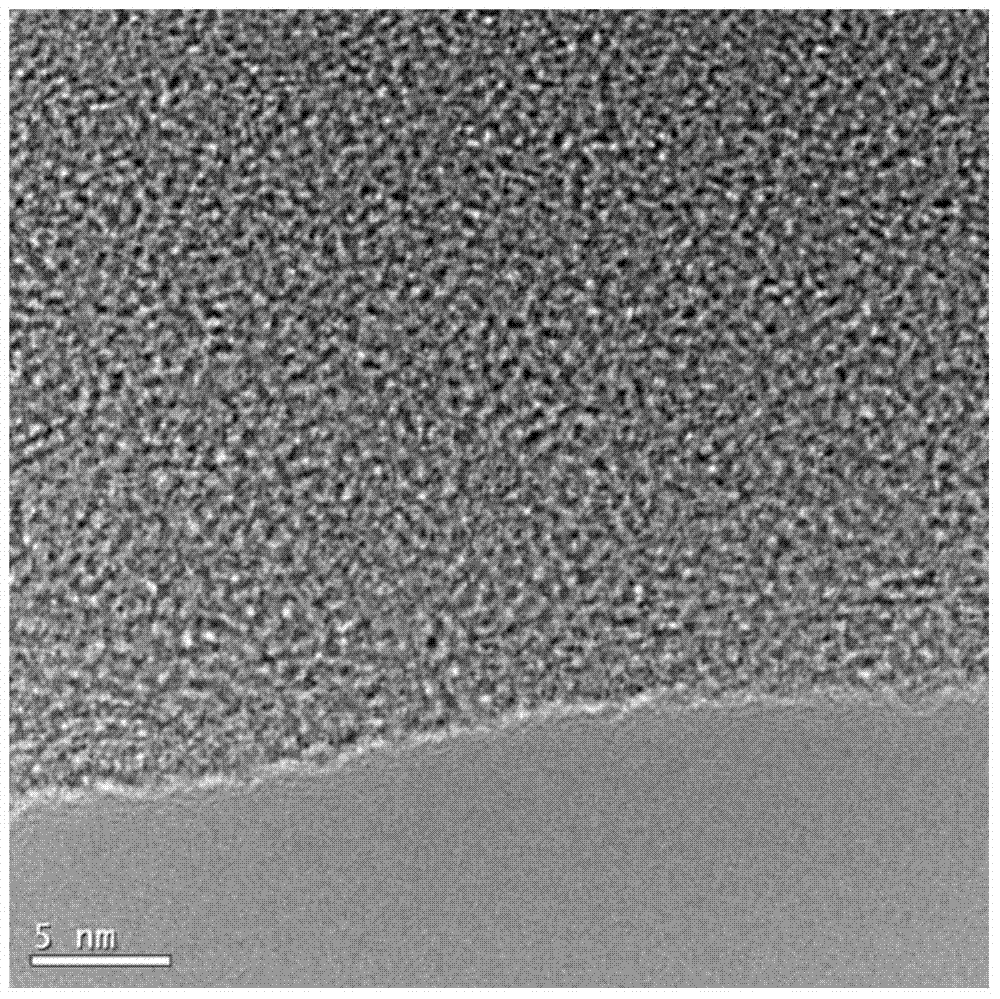

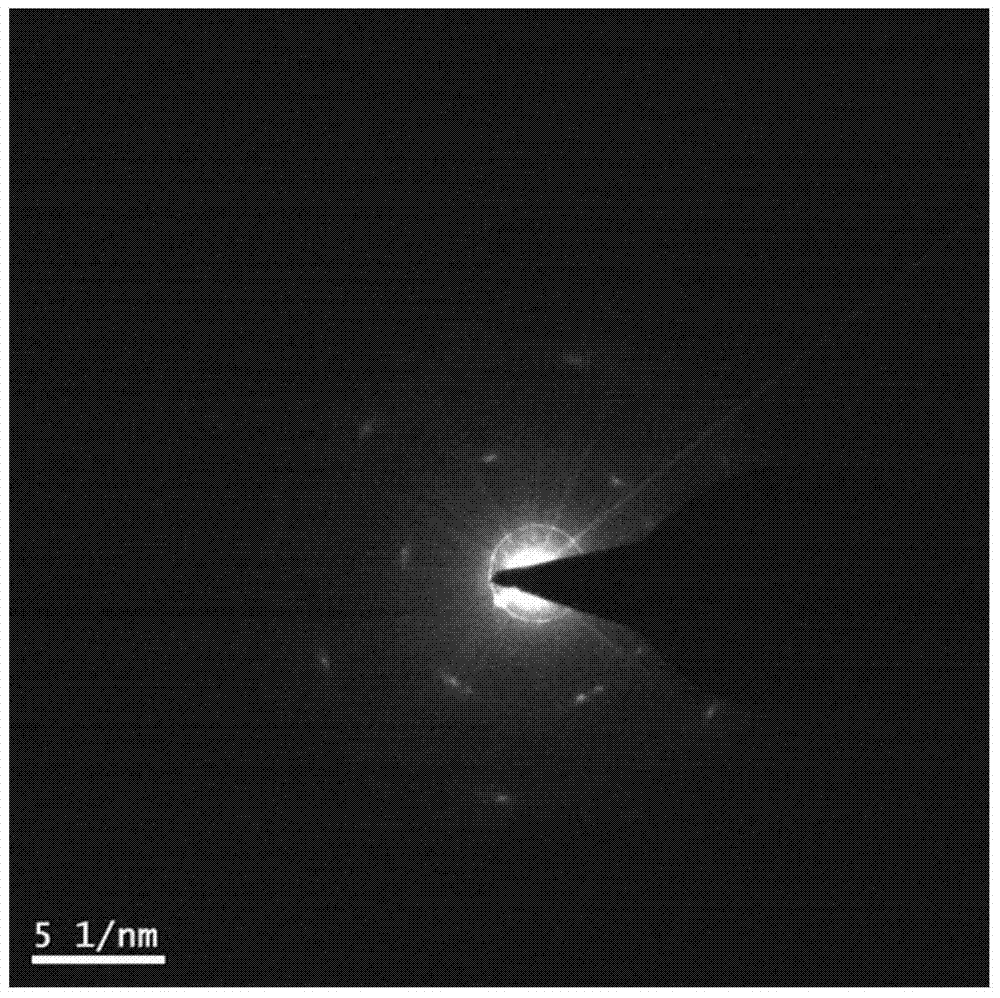

[0054]Embodiment 1: The high-density ordered graphene with ion spacer layer of this embodiment is formed by orderly parallel arrangement of graphene sheets, and alkali metal ions are embedded between graphene sheets as spacer layers, thereby maintaining graphite A dense graphene film material with a microporous structure between ene sheets; wherein, the pores of the high-density ordered graphene with an ion spacer layer are mainly between graphene sheets, which are formed by embedding an alkali metal ion spacer Maintained micropores whose size distribution is mainly between 0.3 and 1 nm; the density of the high-density ordered graphene with an ion spacer layer is 1.2 to 2.1 gcm -3 , the specific surface area is 100~1000m 2 g -1 ; The atomic percent content of the alkali metal ions in the high-density ordered graphene with an ion spacer layer is 0.01-10%.

[0055] The high-density ordered graphene with ion spacer layer of the present embodiment has the following advantages: (...

specific Embodiment approach 2

[0056] Embodiment 2: This embodiment is different from Embodiment 1 in that the alkali metal ions are potassium ions. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0057] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the alkali metal ions are sodium ions. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com