Manufacturing method of electrostatic suction cup, electrostatic suction cup and plasma processing device

An electrostatic chuck and manufacturing method technology, applied in the direction of electrical solid devices, semiconductor/solid device manufacturing, circuits, etc., can solve the problem of destroying the adhesive force between the main body and the base, easily exceeding 100°C, and the main body falling off, etc. Problems, achieve the effect of enhancing plasma resistance, improving service life, and avoiding structural instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below in conjunction with the accompanying drawings of the specification. Of course, the present invention is not limited to this specific embodiment, and general replacements well known to those skilled in the art are also covered by the protection scope of the present invention.

[0026] The manufacturing method of the electrostatic chuck of the present invention will be described in detail below.

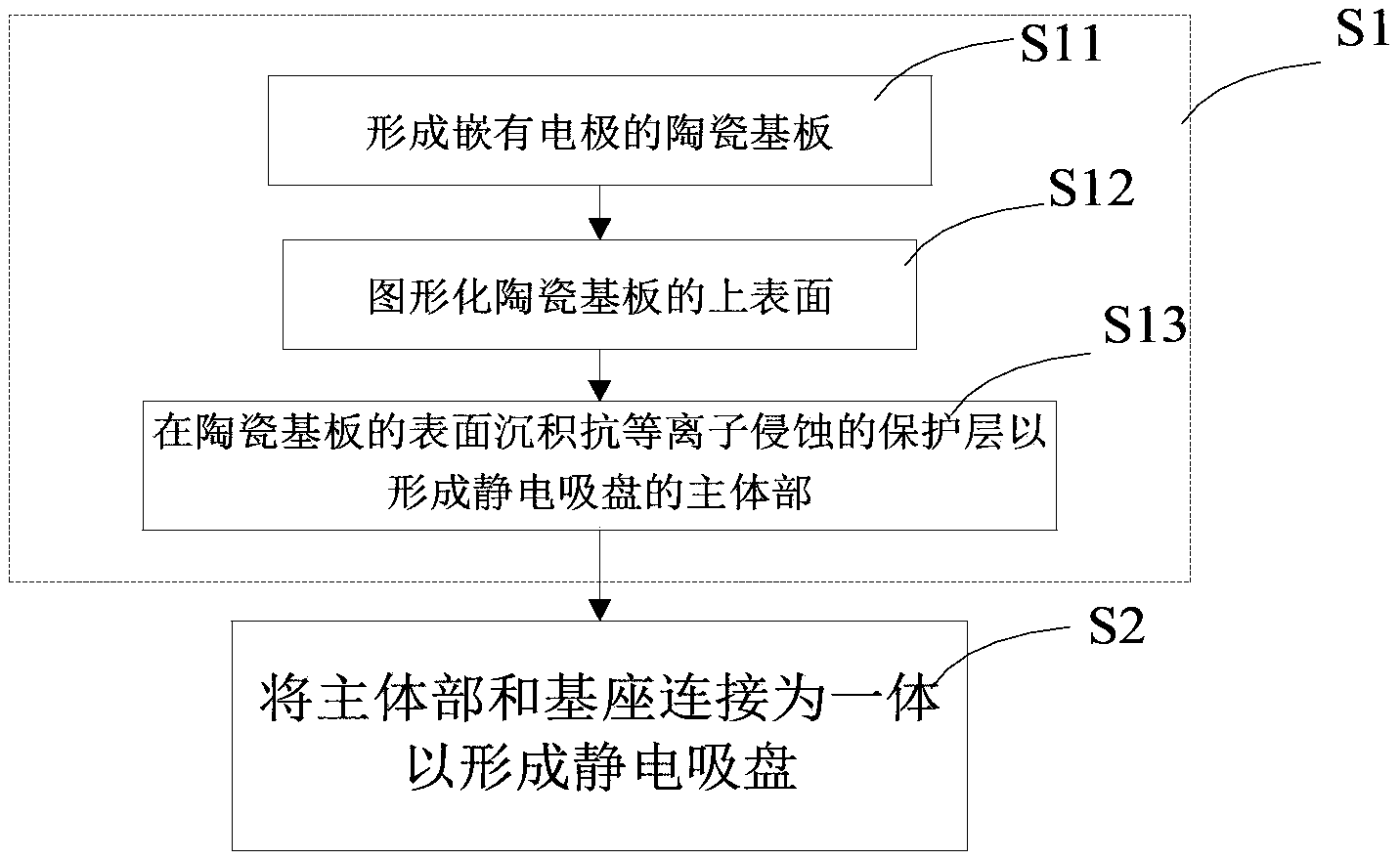

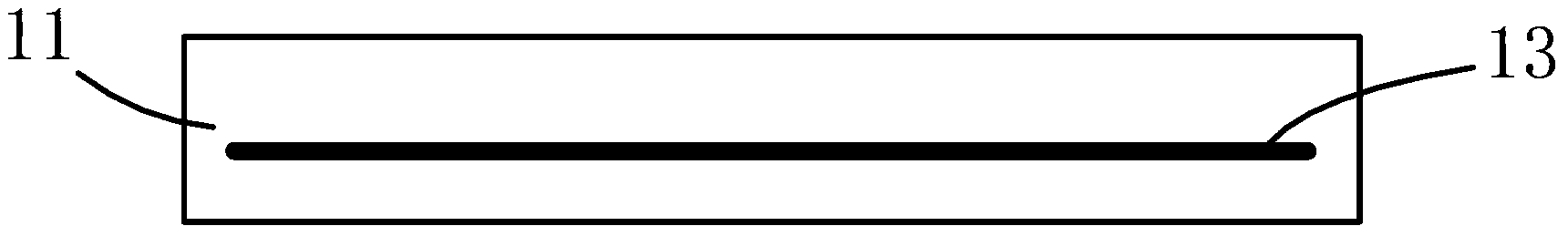

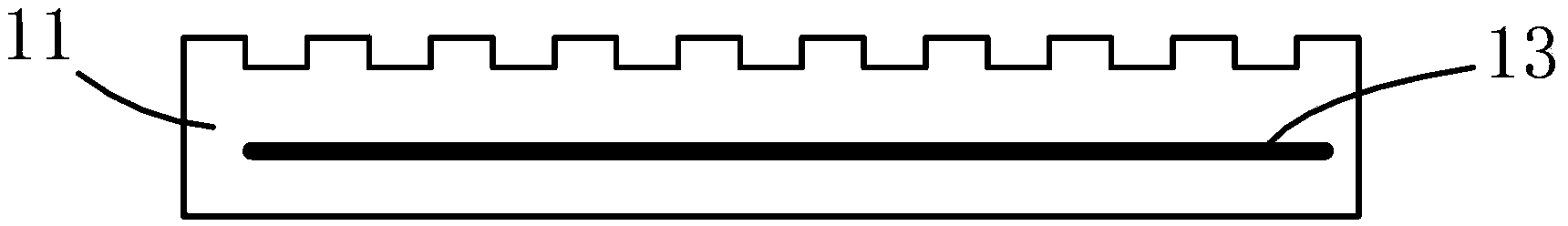

[0027] figure 1 Shown is a schematic flow chart of the manufacturing method of the present invention, which includes the following steps:

[0028] Step S1: manufacturing the electrostatic chuck main body and the base;

[0029] Step S2: Connect the main body and the base to form an electrostatic chuck.

[0030] The electrostatic chuck base is generally made of metal such as aluminum, titanium alloy, or stainless steel, which is conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com