Treatment method for liquid sulfur degassing in sulfur recovery process

A technology for liquid sulfur degassing and sulfur recovery, which is used in sulfur preparation/purification, chemical industry, climate sustainability, etc., and can solve problems such as substandard discharge and unsatisfactory sulfur liquid sulfur degassing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

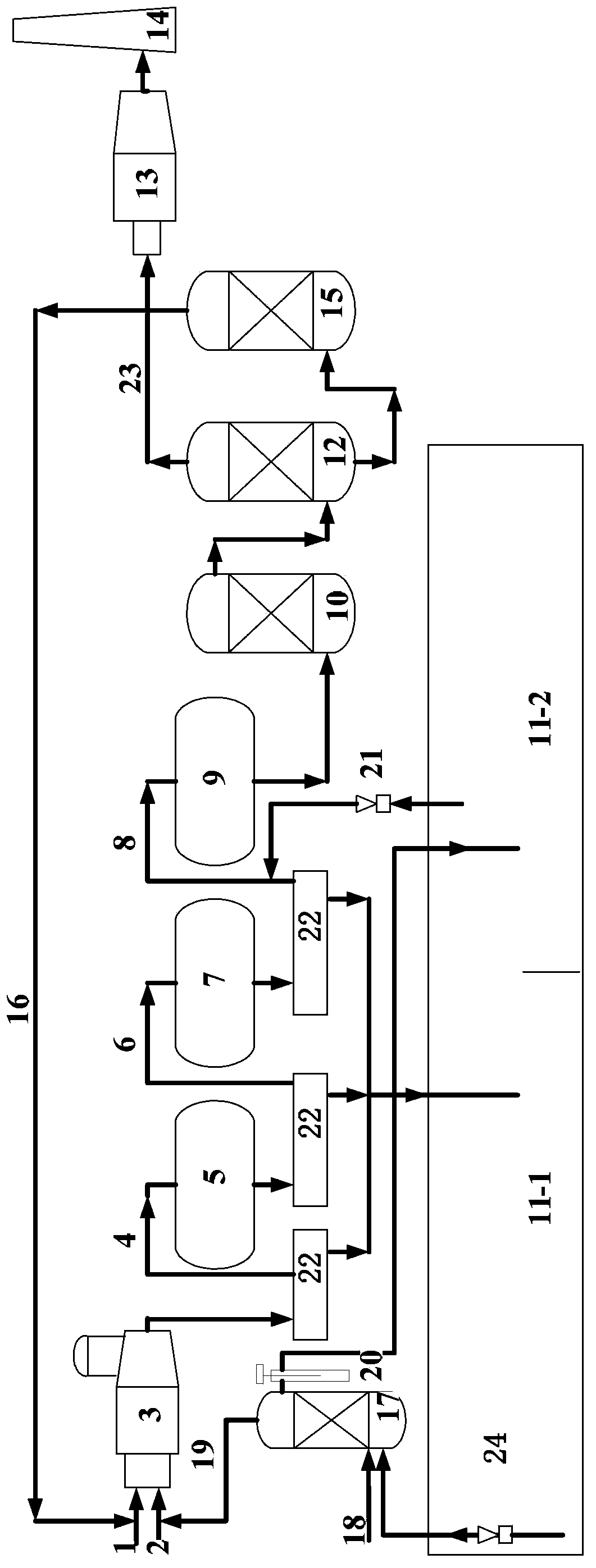

[0046] process such as figure 1 As shown, it includes thermal reaction stage, catalytic reaction stage, tail gas purification treatment stage and liquid sulfur degassing treatment stage.

[0047] 1) Thermal reaction stage:

[0048] Contains H 2 S: 30-100 (v / v)% acid gas (1) and air (2) are partially combusted into SO in the sulfur furnace (3) 2 , in the sulfur furnace (3) at high temperature (900-1400°C) H 2 S and SO 2 A Claus reaction occurs to generate elemental sulfur and sulfur-making furnace tail gas (4), the elemental sulfur condenses and enters the undegassed compartment (11-1) of the liquid sulfur pool (11) to recover liquid sulfur, and the sulfur-making furnace tail gas (4) enters catalytic reaction stage. The volume content of sulfur-containing compounds in the tail gas (4) of the sulfur making furnace is: H 2 S: 1-8%, SO 2 : 0.5-4%, organic sulfur: 0-2%.

[0049] 2) Catalytic reaction stage:

[0050] The tail gas (4) of the sulfur making furnace enters the ...

Embodiment 2

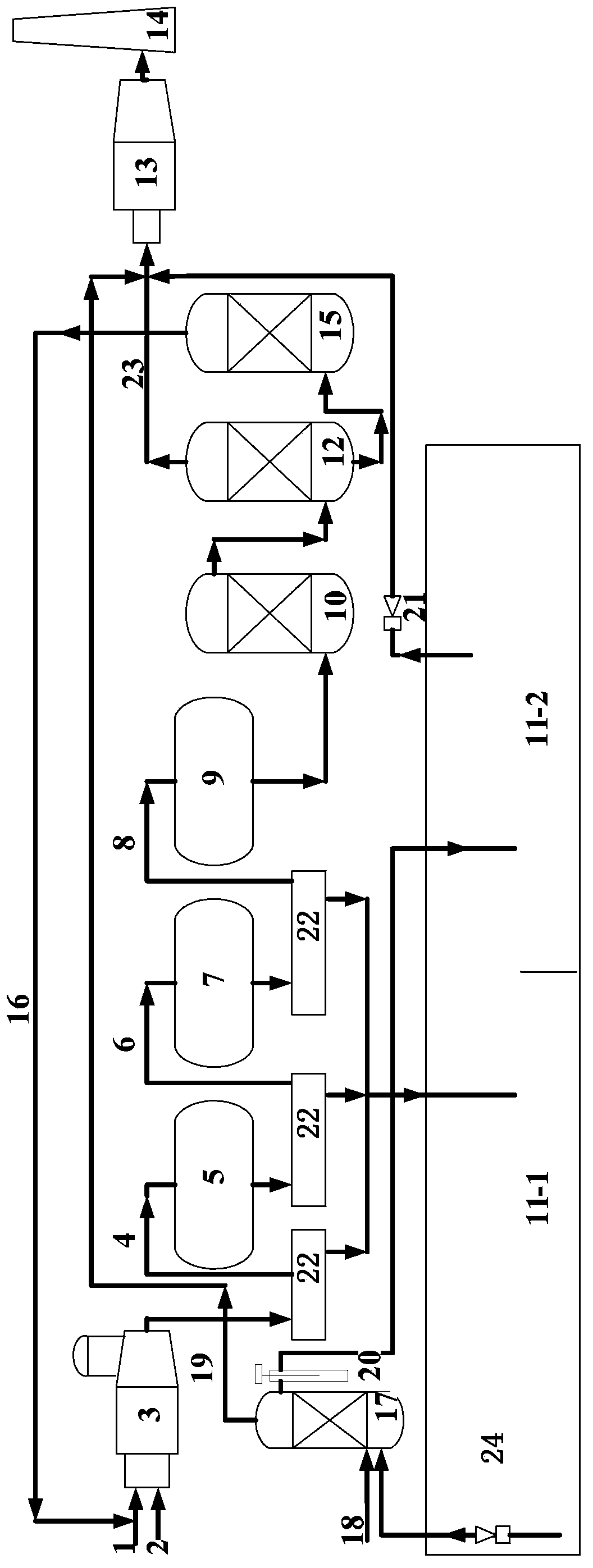

[0058] Except following difference, other is with embodiment 1.

[0059] process such as figure 2 shown.

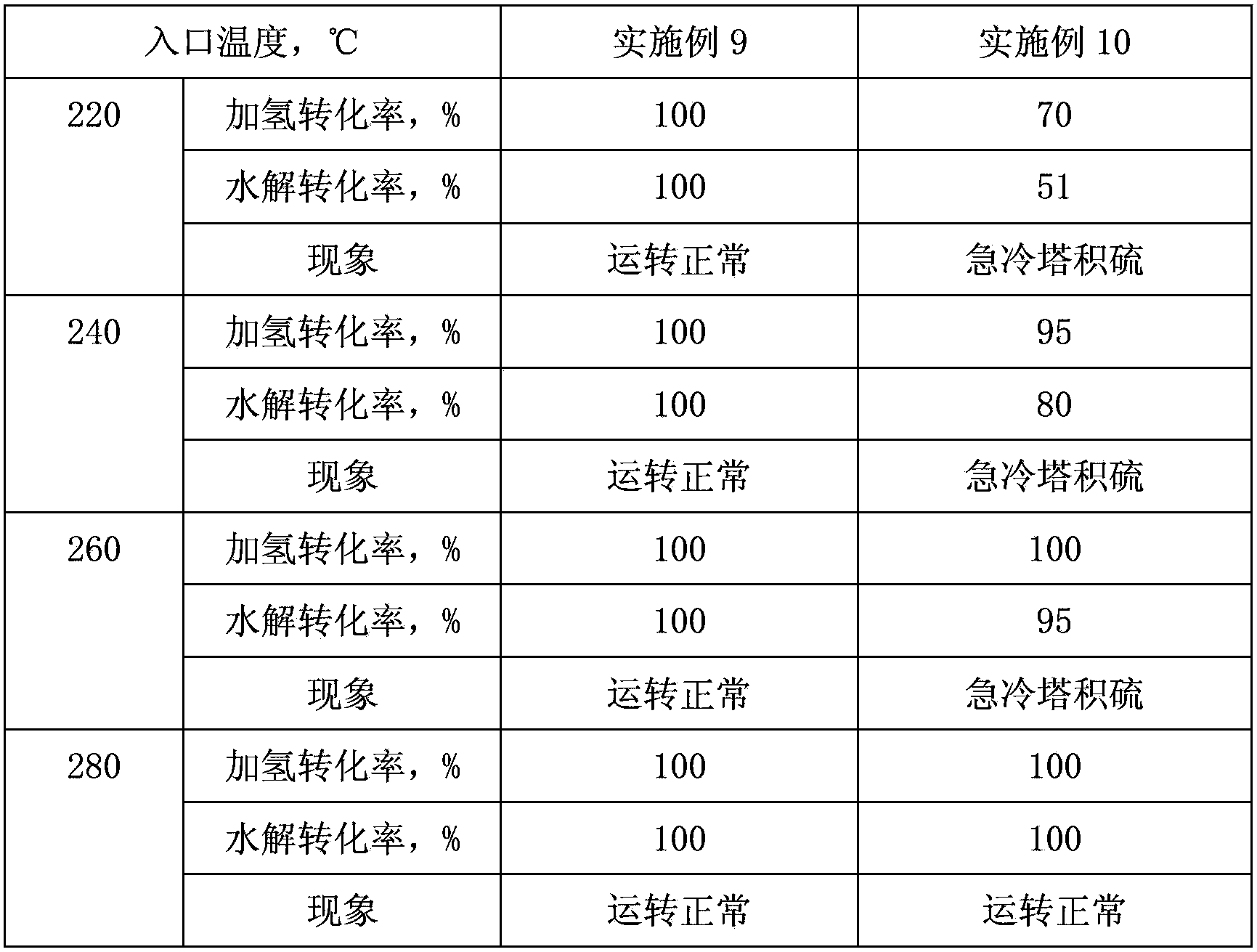

[0060] The degassed waste gas (19) produced by the liquid sulfur degassing tower (17) and the sulfur-containing waste gas extracted by the steam extractor (21) are all introduced into the incinerator (13) to be incinerated and converted into SO 2 After being discharged through the chimney, the flue gas SO 2 Emission concentration 400-960mg / m 3 between. Hydrogen sulfide content in liquid sulfur and flue gas SO 2 The emission concentration is shown in Table 1.

Embodiment 3

[0062] Except following difference, other is with embodiment 1.

[0063]Close the liquid sulfur degassing tower (17), and only rely on the steam extractor (21) to extract the sulfur-containing waste gas volatilized at the top of the liquid sulfur tank, and then introduce the sulfur-containing waste gas into the hydrogenation reactor (9) for processing. Hydrogen sulfide content in liquid sulfur and flue gas SO 2 The emission concentration is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com