Cation-doped and modified lithium ion battery (4:4:2)type ternary cathode material and preparation method thereof

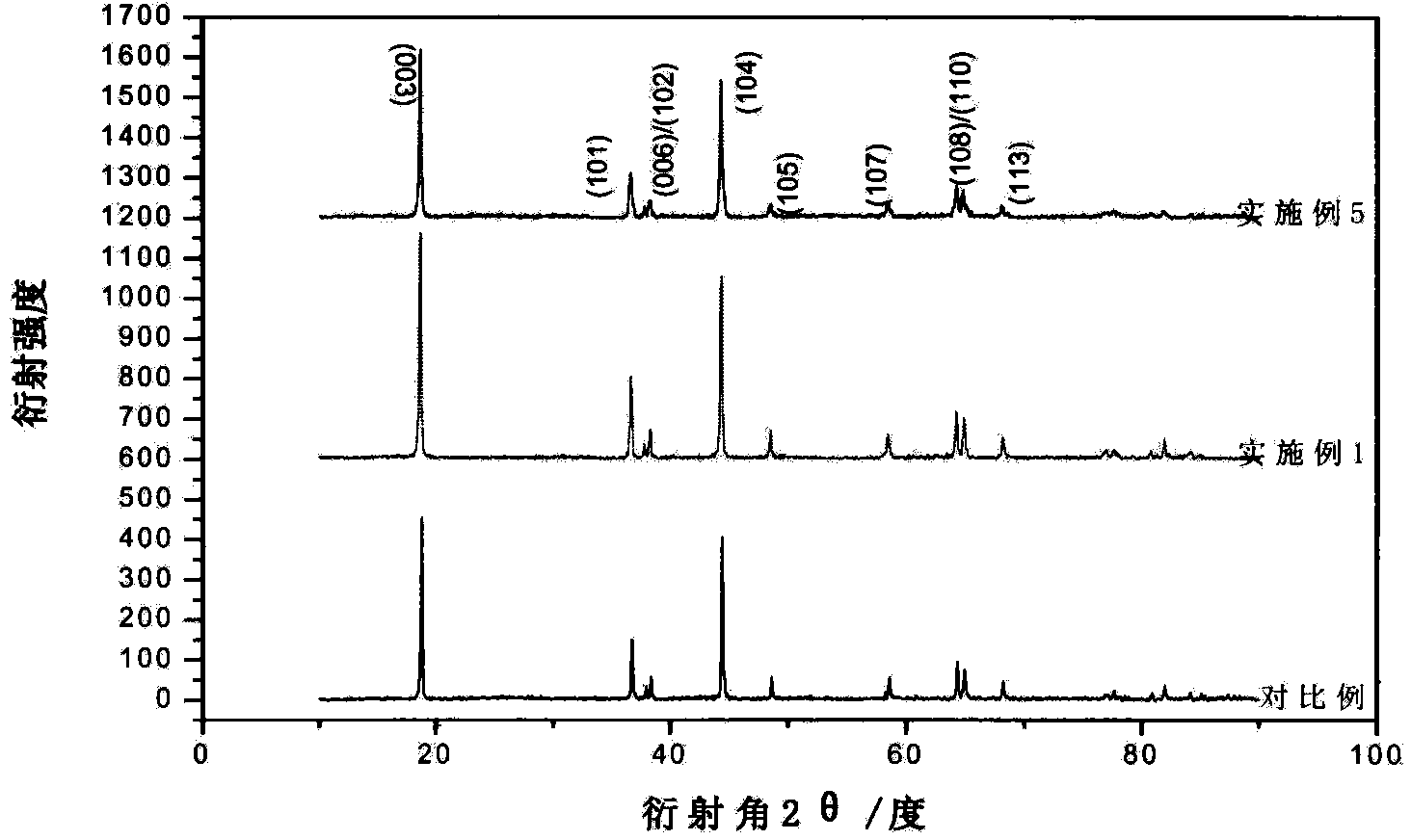

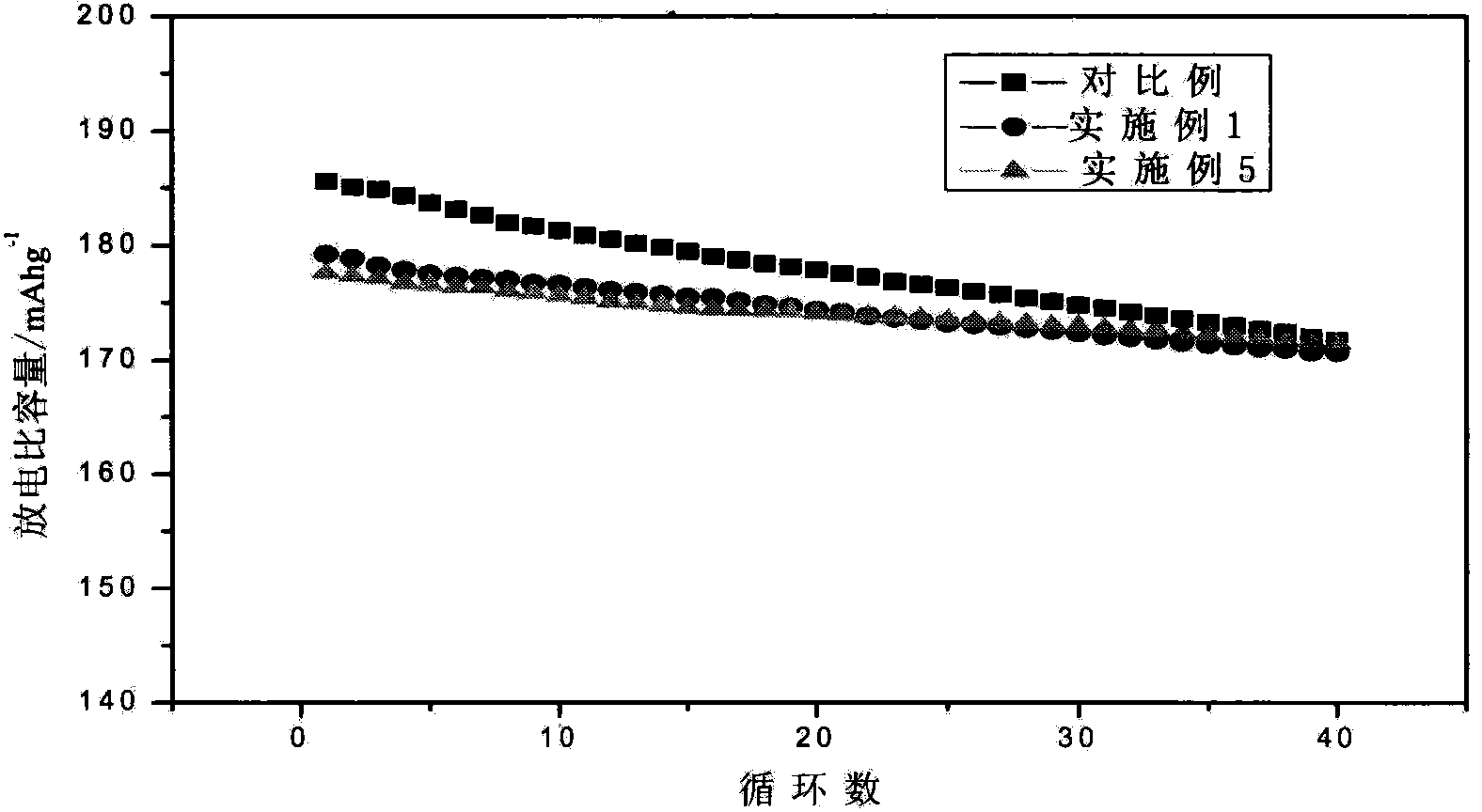

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of insufficient cycle performance and rate performance of ternary materials, achieve excellent cycle performance and rate performance, promote commercialization, The effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of gel: Weigh analytically pure CH according to the stoichiometric ratio (1.05:0.35:0.2:0.4:0.05). 3 COOLi·2H 2 O, Ni(CH 3 COO) 2 4H 2 O, Co(CH 3 COO) 2 4H 2 O, Mn(CH 3 COO)·4H 2 O, Mg(NO 3 ) 2 ·6H 2 O, dissolve completely with deionized water respectively, add citric acid solution, the amount added is equal to the sum of molar amounts of transition metal ions, mix well, adjust the pH value to about 7 with concentrated ammonia water, heat in a water bath at 60°C and keep Stir until a dark purple gel is obtained;

[0023] (2) Burning: take the gel prepared in step (1) and heat and dry at 80°C for 8 hours, pre-burn the resulting product at 300°C for 4 hours, cool and grind, then calcinate at 700°C for 10 hours, cool and grind , to get the product LiNi 0.35 co 0.2 mn 0.4 Mg 0.05 o 2 Cathode material.

Embodiment 2

[0025] (1) Preparation of gel: Weigh analytically pure LiNO according to the stoichiometric ratio (1.05:0.3:0.2:0.4:0.1) 3 , Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Mn(NO 3 ) 2 4H 2 O, Cu(NO 3 ) 2 ·3H 2 O, dissolve completely with deionized water respectively, add citric acid solution, the amount added is equal to the sum of molar amounts of transition metal ions, mix evenly, adjust the pH value to about 7.5 with concentrated ammonia water, heat in a water bath at 80°C and continuously Stir until a dark purple gel is obtained;

[0026] (2) Burning: Burning: Take the gel prepared in step (1) and heat and dry at 100°C for 10 hours, pre-burn the resulting product at 400°C for 5 hours, cool and grind, and then calcinate at 850°C for 15 hours After cooling and grinding, the product LiNi is obtained 0.3 co 0.2 mn 0.4 Cu 0.1 o 2 Cathode material.

Embodiment 3

[0028] (1) Preparation of gel: Weigh analytically pure LiOH·H 2 O, Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Mn(NO 3 ) 2 4H 2 O, Zn(NO 3 ) 2 ·6H 2 O, dissolve completely with deionized water, add citric acid solution, the amount is equal to the sum of the molar amounts of transition metal ions, mix well, adjust the pH value to about 8 with concentrated ammonia water, heat in a water bath at 90°C and keep Stir until a dark purple gel is obtained;

[0029] (2) Burning: 2) Burning: take the gel prepared in step (1) and heat and dry at 120°C for 12 hours, pre-burn the resulting product at 500°C for 6 hours, then cool and grind, and then calcined at 900°C Cool and grind after 18 hours to obtain the product LiNi 0.25 co 0.2 mn 0.4 Zn 0.15 o 2 Cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com