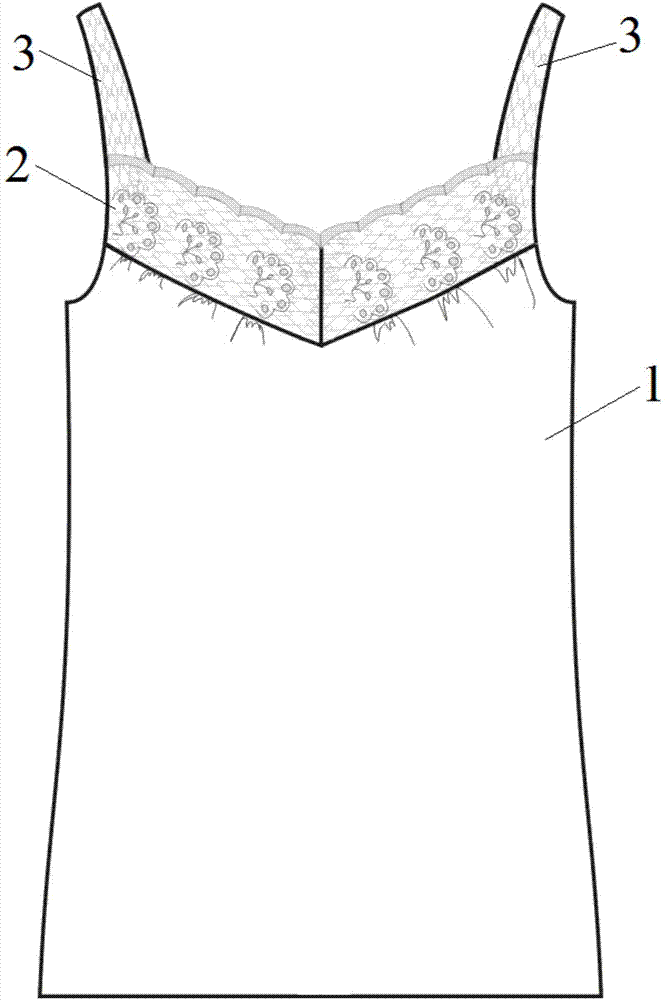

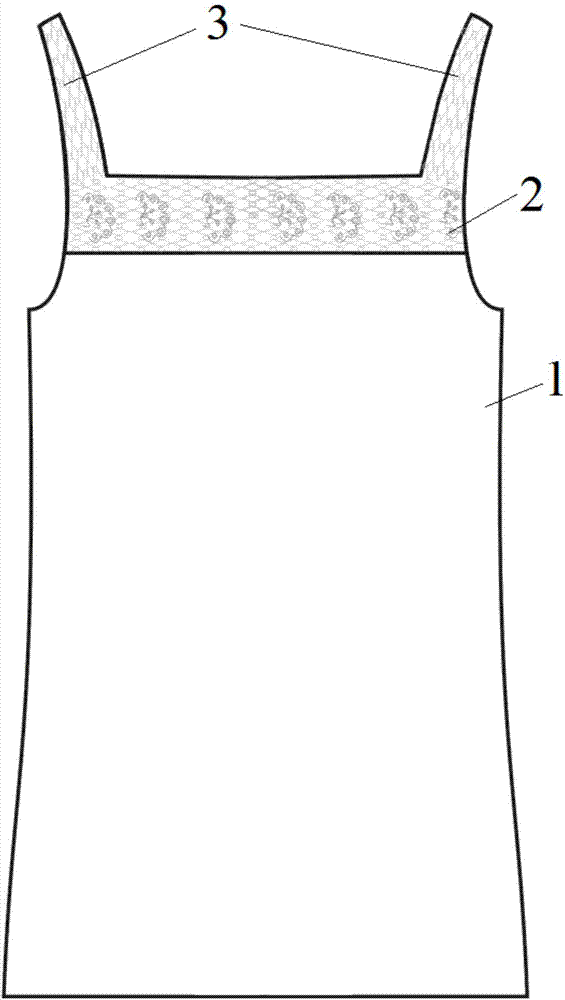

Underwaist

A vest and fabric technology, applied in the field of vests, can solve the problems of increased moisture regain of brown carbon fiber, air permeability, anti-pilling and insufficient wrinkle recovery, etc., and achieve the effect of improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The fabric used to make the body of the vest contains 100% coffee fiber, that is, the fabric is a fabric made of coffee fiber, which has the characteristics of moisture absorption, quick drying, deodorization, environmental protection, and UV protection. It is a new type of fabric that allows The waste coffee grounds are properly used, and the characteristics of coffee fiber bring consumers a refreshing and comfortable enjoyment, and more importantly, environmentally friendly recycling, which does not increase the burden on the earth, but has a sense of participation in energy saving and carbon reduction. .

Embodiment 2

[0026] The fabric used to make the body of the vest contains 25% coffee fiber, 35% viscose fiber, 35% modal fiber and 5% bamboo fiber, and the proportions are percentages by weight. That is, the fabric is a blended fabric composed of a variety of fibers. With the addition of viscose fiber, modal fiber, etc., the air permeability, anti-pilling, drape and wrinkle recovery properties of the vest can be improved.

Embodiment 3

[0028] The fabric used to make the body of the vest contains 25% coffee fiber, 35% viscose fiber, 35% modal fiber and 5% cotton fiber, and the proportions are percentages by weight. That is, the fabric is a blended fabric composed of a variety of fibers. With the addition of viscose fiber, modal fiber, etc., the air permeability, anti-pilling, drape and wrinkle recovery properties of the vest can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com