Nano-microscale reaction separation coupled multifunctional catalyst and preparation method thereof

A reaction separation coupling, catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as the reduction of n-butane conversion rate, achieve selectivity and improve catalytic performance, avoid pollution, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

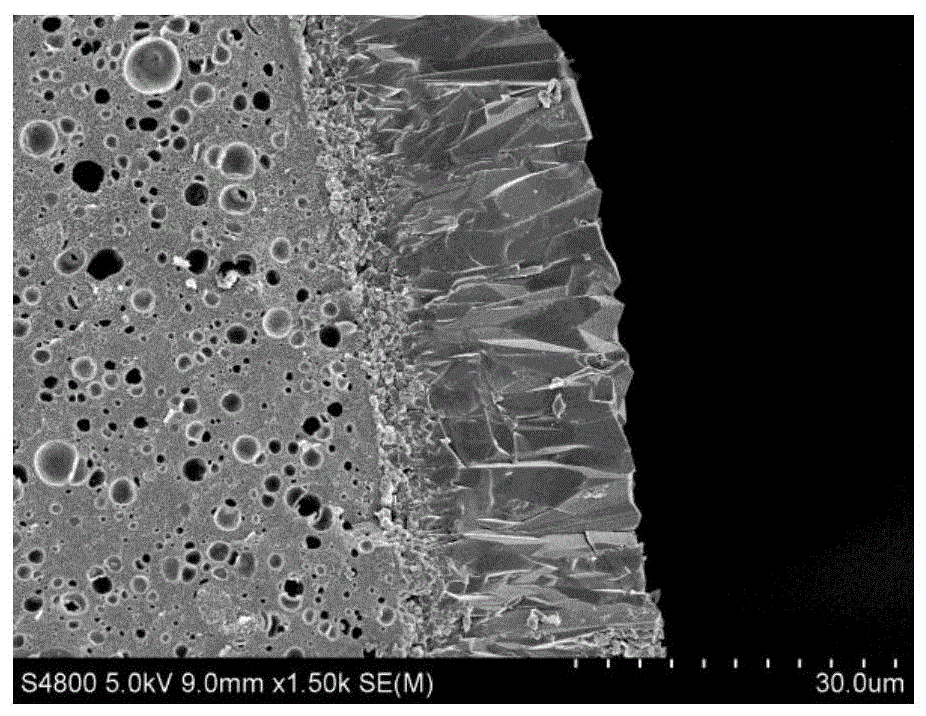

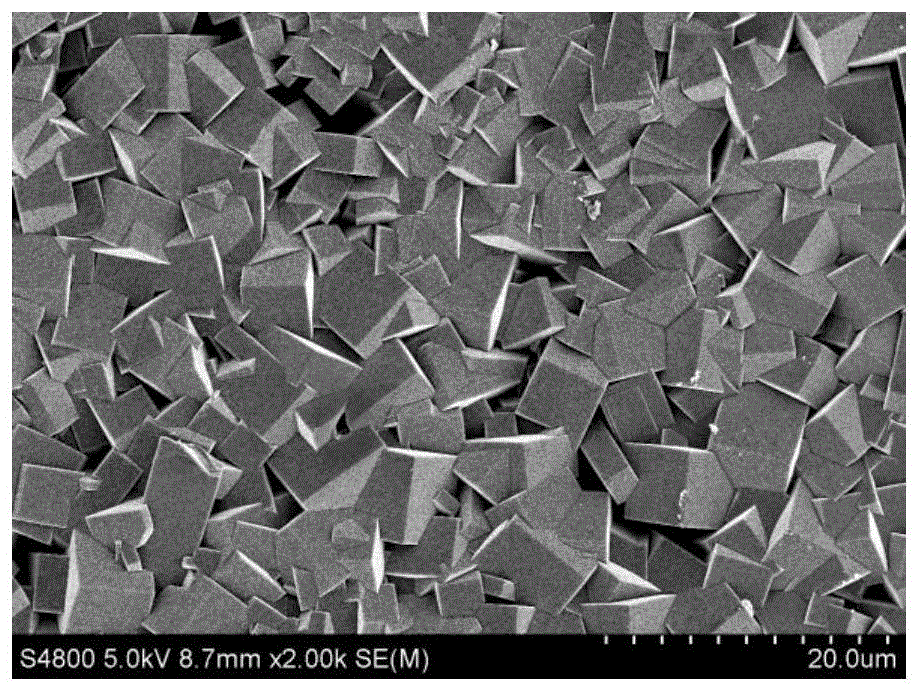

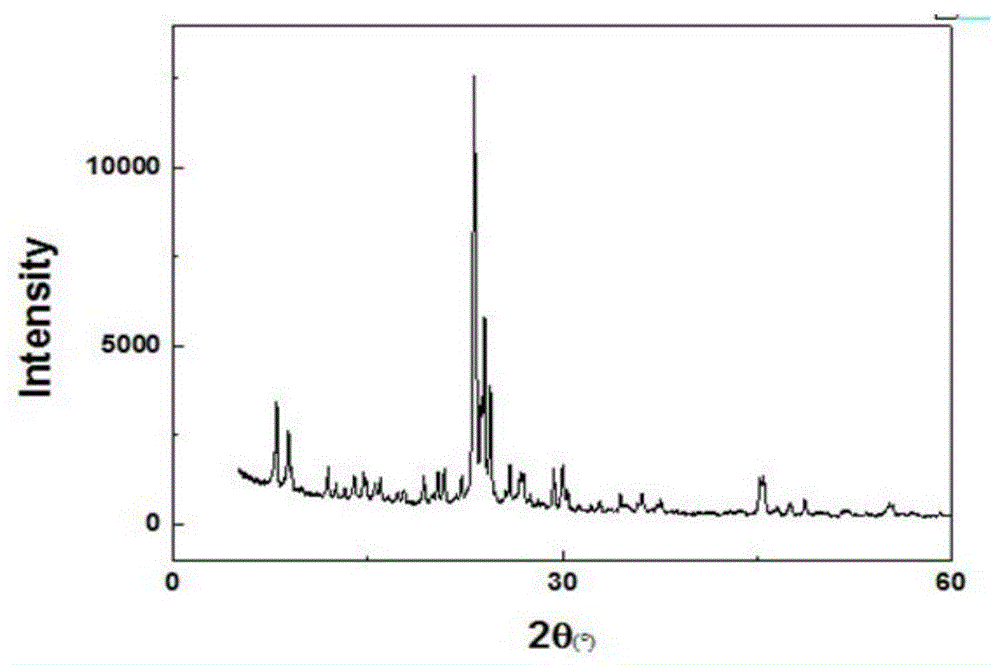

[0034] At room temperature, 10ml of 5wt% nickel nitrate aqueous solution was impregnated in 2g of SiO 2 on, let it stand for 30min; the impregnated SiO 2 Dry in an oven at 60°C for 2h, and then bake in a muffle furnace at 500°C for 2h; the cooled SiO 2 Put it in 10ml 1wt% KOH solution, put it into a hydrothermal reaction kettle, and treat it in an oven at 60°C for 2h; the cooled SiO 2 Soak in 6wt% polymethacrylate aqueous solution for 2h, then wash with dilute ammonia for 3 times, and dry in an oven at 60°C for 2h; the treated SiO 2 Placed in a seed solution containing 15wt% of Silicalite-1 with a scale of 50-100nm, after adsorption for 3 hours, washed with deionized water for 3 times, and then placed in a 60°C oven for 2h, in a muffle furnace at 500°C Roasting 2h; After roasting, the composition is placed in (TPAOH:TEOS:H 2 (O=1:30:4500) solution, placed in a crystallization kettle and reacted at 100°C for 8h to obtain the product, washed 5 times with deionized water, then...

Embodiment 2

[0036] At room temperature, 10ml of 0.1wt% chloroplatinic acid aqueous solution was impregnated in 2g of Al by vacuum impregnation method. 2 o 3 on, let it stand for 30min; the impregnated Al 2 o 3 Put it in an oven at 60°C for 2 hours, then put it in a muffle furnace and bake it at 500°C for 2 hours; put the cooled Al2O3 in 10ml of 1wt% NaOH solution, put it in a hydrothermal reaction kettle, and treat it in an oven at 60°C for 2 hours ; the cooled Al 2 o 3 Soak in 2.4wt% diethylene glycol diacrylate phthalate aqueous solution for 2 hours, then wash with dilute ammonia for 3 times, and dry in an oven at 60°C for 2 hours; the treated Al 2 o 3 Placed in a solution containing 15wt% ZSM-5 seed crystals, adsorbed for 3 hours, washed 3 times with deionized water, then placed in a 60°C oven for 2h, and roasted at 500°C in a muffle furnace for 2h; The product is placed in the composition (NaOH: TPAOH: TEOS: H 2 O: Al 2 (SO 4 ) 3 =1:15:60:5500:2), put it in a crystallization...

Embodiment 3

[0038] At room temperature, 10ml of 0.2wt% palladium chloride and 0.05wt% chloroplatinic acid aqueous solution was impregnated on 2g Y-type molecular sieves by conventional impregnation method, and left to stand for 30min; the impregnated molecular sieves were dried in an oven at 60°C for 2h, Place in a muffle furnace and roast at 500°C for 2h; put the cooled molecular sieve in 10ml 1wt% tetrapropylammonium hydroxide solution, put it in a hydrothermal reaction kettle, and treat it in an oven at 60°C for 2h; put the cooled molecular sieve Molecular sieves were soaked in 0.8wt% diethylene glycol diacrylate phthalate aqueous solution for 2 hours, then washed 3 times with dilute ammonia water, and dried in an oven at 60°C for 2 hours; the treated molecular sieves were placed in 30wt% Silicalite In the solution of -1 seed crystal, after adsorption for 2h, wash with deionized water 3 times, then place it in a 60°C oven for 2h, and then roast it in a muffle furnace at 500°C for 2h; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com