Method for culturing full autotrophic denitrification granular sludge in continuous flow reactor

A whole-process autotrophic denitrification and granular sludge technology, applied in the field of wastewater autotrophic denitrification, can solve the problems of complex operation and management, slow growth rate, unfavorable granular sludge, etc., and achieve convenient operation and management, gas-liquid mass transfer The effect of high efficiency and saving reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

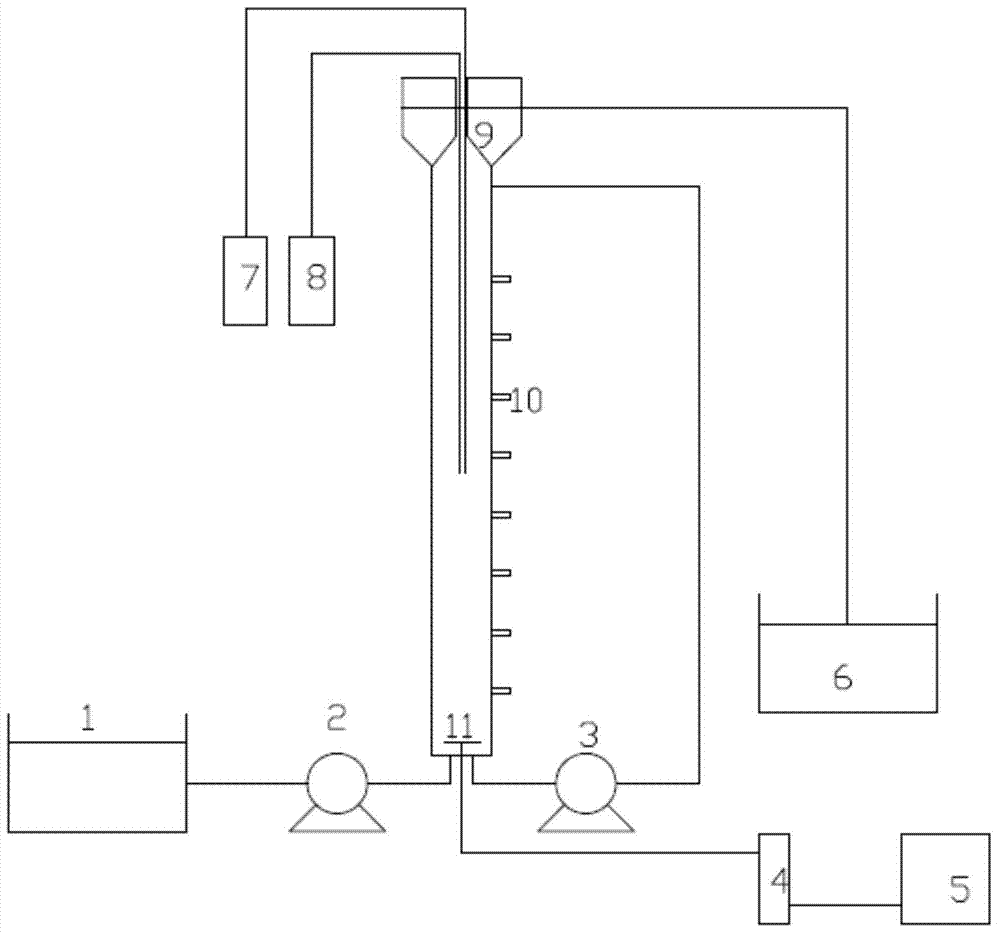

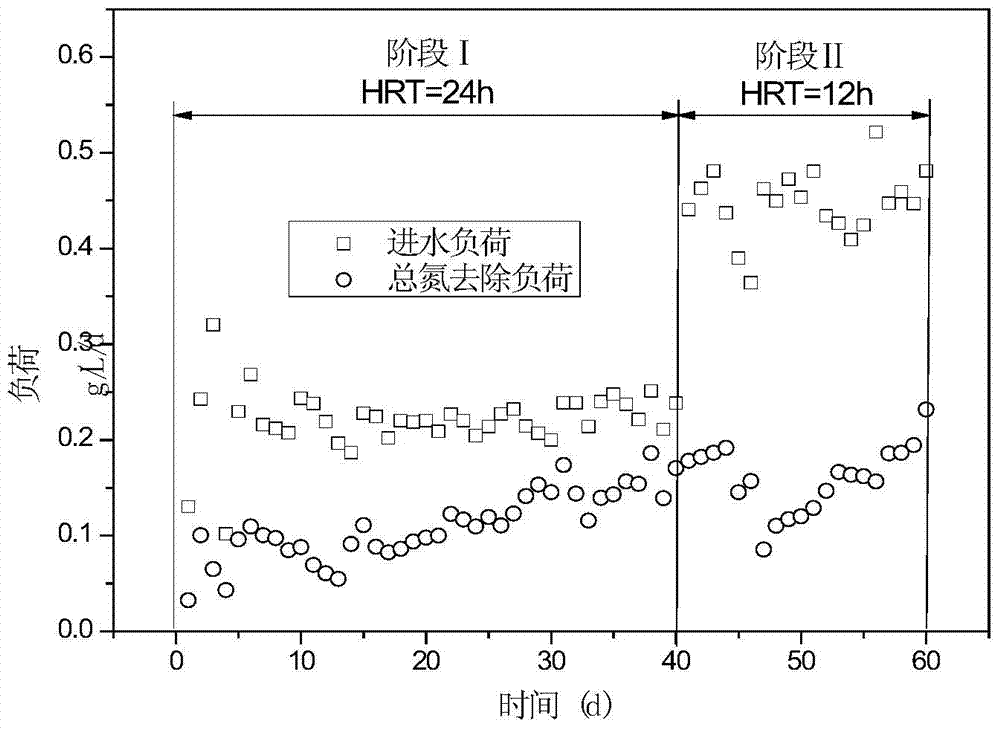

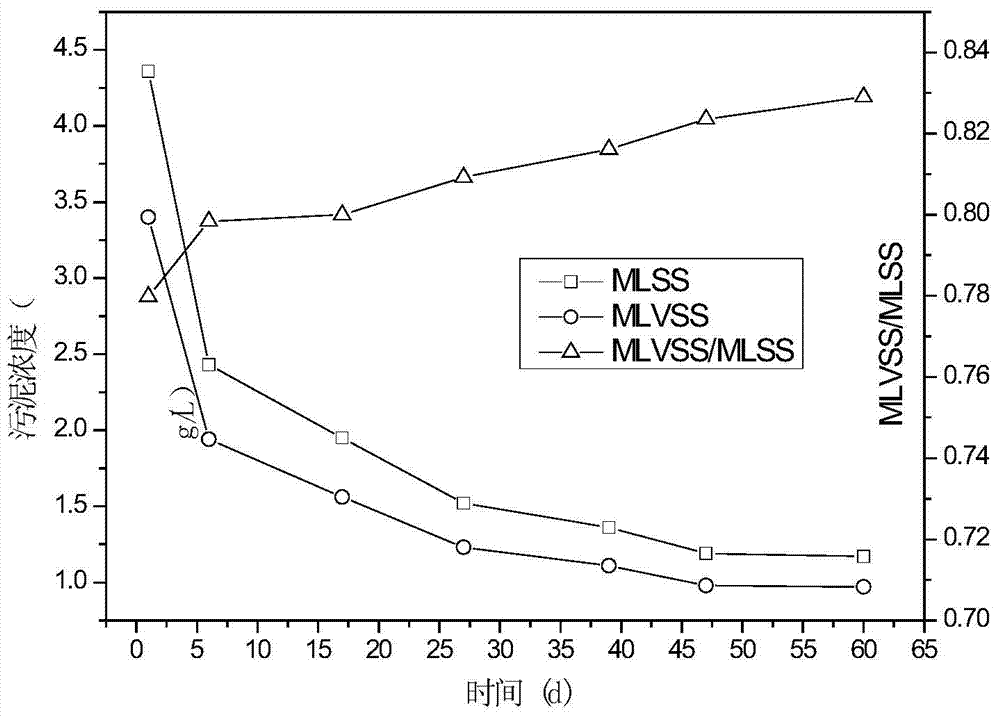

[0020] The reactor adopted in the present invention is made of plexiglass, with a total volume of 24L, an effective volume of 12L, and an inner diameter of 8cm. An aeration device and a water inlet are installed at the bottom of the reactor, and a three-phase separator is installed at the top of the reactor. After the sludge is intercepted by the three-phase separator, the effluent flows away from the overflow weir at the top of the reactor. Set the return port between them. The test water was artificially synthesized wastewater, with (NH 4 ) 2 SO 4 as the base, Concentration 200mg / L, pH by NaHCO 3 Adjust between 7.8-8.2, while using NaHCO 3 Provide an inorganic carbon source and add an appropriate amount of Ca to the influent 2+ , Mg 2+ and trace elements needed for microbial growth. The inoculum sludge is biofilm from CANON biofiltration column, MLSS is 4.36g / L, MLVSS is 3.4g / L, and MLVSS / MLSS is 0.78. The reactor does not control the temperature, the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com