A kind of zirconia composite ceramics and preparation method thereof

A technology of composite ceramics and zirconia, which is applied in the field of zirconia composite ceramics and its preparation, high hardness zirconia composite ceramics and its preparation, and high strength and toughness. It can solve the problems of high toughness and high strength that are difficult to match, and reduce microscopic defects. , The preparation process is simple, and the effect of solving the reduction of the overall performance of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

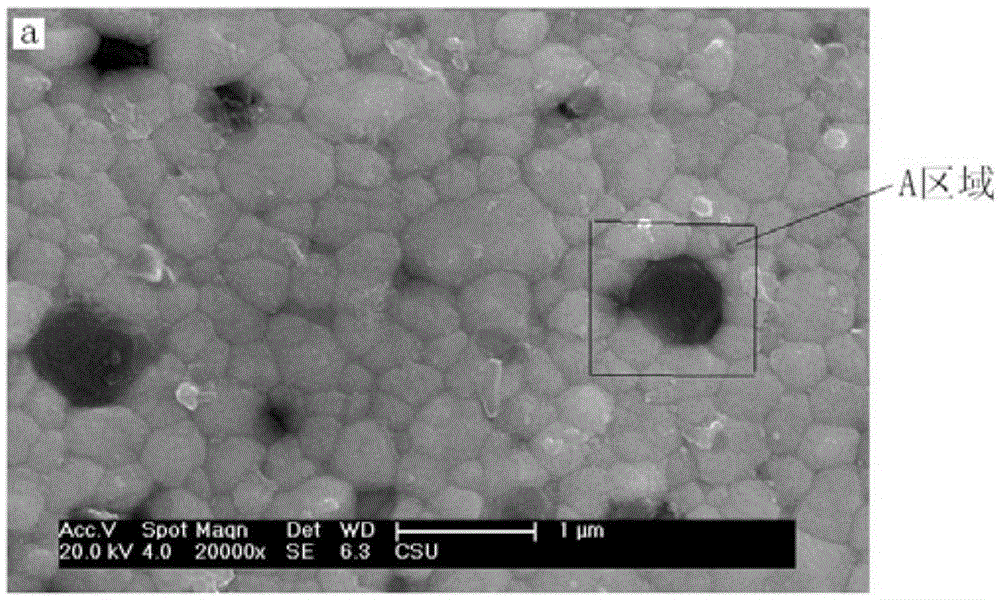

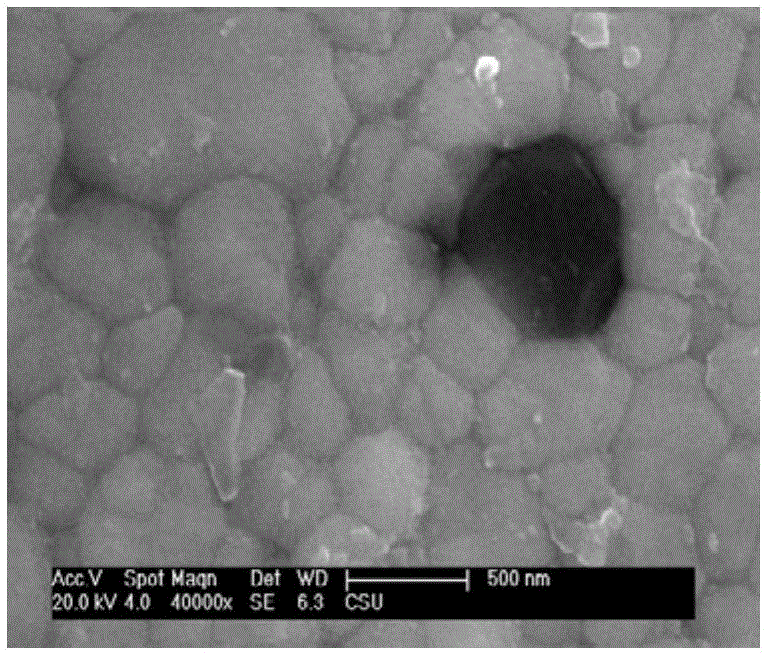

Image

Examples

Embodiment 1

[0054] By mass ratio, nano-TiO 2 Powder: Nano B 2 O 3 Powder = 1.20:1, with nano-TiO 2 Powder (TiO 2 particle size of 50nm) and nano-B 2 O 3 powder (B 2 O 3 The particle size is 50nm);

[0055] Then press the assigned B 2 O 3 Powder and TiO 2 The ratio of total powder mass to carbohydrate mass is 1:8 to prepare sucrose powder (the particle size of sucrose powder is 200nm, and the mass percentage of C element is about 42.1%);

[0056] Then the prepared TiO 2 powder, B 2 O 3 The powder and sucrose powder were ground and mixed, and the temperature was raised to 200 °C under an argon atmosphere, and the temperature was maintained for 3 h. The carbon coating pretreatment was carried out to obtain a carbon coating modified (TiO 2 +B 2 O 3 ) mixed powder. 75.0wt.% ZrO with 50nm nanoparticle size 2 Modified with 25wt.% (TiO 2 +B 2 O 3 ) The mixed powder was weighed and mixed according to the mass ratio, placed in a zirconia ball milling tank, and ball-milled for 1...

Embodiment 2

[0059] By mass ratio, nano-TiO 2 Powder: Nano B 2 O 3 Powder = 1.30:1, with nano-TiO 2 Powder (TiO 2 particle size of 300nm) and nano-B 2 O 3 powder (B 2 O 3 The particle size is 300nm);

[0060] Then press the assigned B 2 O 3 Powder and TiO 2 The ratio of total powder mass to carbohydrate mass is 1:9 to prepare sucrose powder (the particle size of sucrose powder is 500nm);

[0061] Then the prepared TiO 2 powder, B 2 O 3 The powder and sucrose powder were ground and mixed uniformly, and the temperature was raised to 350 °C in an argon atmosphere, kept for 4 h, and carbon-coated pretreatment was performed to obtain a carbon-coated modified (TiO 2 +B 2 O 3 ) mixed powder. 80.0wt.% ZrO with 100nm nanoparticle size 2 Modified with 20.0 wt.% (TiO 2 +B 2 O 3 ) The mixed powder is weighed and mixed according to the mass ratio, placed in a zirconia ball milling tank, and ball-milled for 24 hours with anhydrous ethanol as a solvent. Dry the slurry obtained by ba...

Embodiment 3

[0064] By mass ratio, nano-TiO 2 Powder: Nano B 2 O 3 Powder = 1.30:1, with nano-TiO 2 Powder (TiO 2 particle size of 500nm) and nano-B 2 O 3 powder (B 2 O 3 The particle size is 500nm);

[0065] Then press the assigned B 2 O 3 Powder and TiO 2 The ratio of total powder mass to carbohydrate mass is 1:10 to prepare glucose powder (the particle size of glucose powder is 700nm);

[0066] Then the prepared TiO 2 powder, B 2 O 3 The powder and glucose powder were ground and mixed, and the temperature was raised to 500 °C in an argon atmosphere, kept for 5 h, and carbon-coated pretreatment was performed to obtain a carbon-coated modified (TiO 2 +B 2 O 3 ) mixed powder. 90.0wt.% ZrO with 300nm nanoparticle size2 Modified with 10.0wt.% (TiO 2 +B 2 O 3 ) The mixed powder is weighed and mixed according to the mass ratio, placed in a zirconia ball milling tank, and ball-milled for 24 hours with anhydrous ethanol as a solvent. Dry the slurry obtained by ball milling, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com