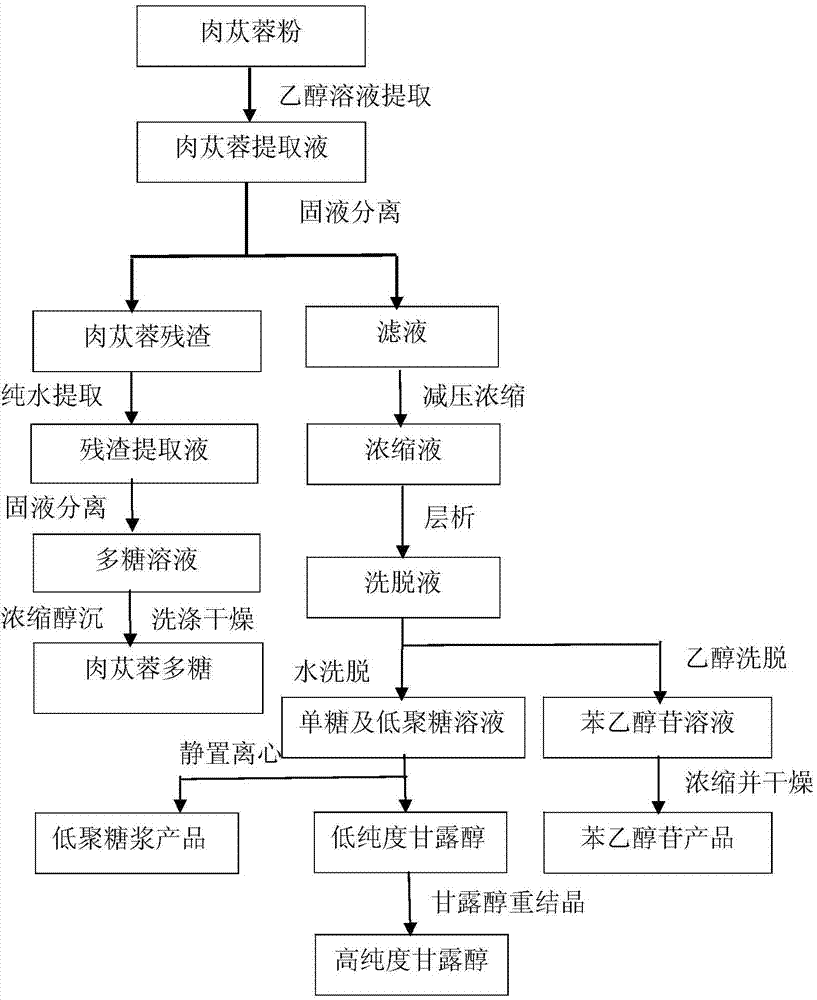

Method for preparing phenylethanoid glycoside, mannitol, oligosaccharide syrup and polysaccharide from broomrape

A technology of phenylethanoid glycosides and oligosaccharide syrup, which is used in the preparation of oligosaccharides and sugar derivatives, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Take desert cistanche 100kg, crush through a 40-mesh sieve, add 1.5m 3 50% ethanol solution, 55 ℃ under ultrasonic enhanced extraction (ultrasonic power is 300W) 100min, extract 1 time, extract liquid 500 order filter cloth filter, filtrate decompression concentrates, obtains concentrated liquid I altogether 340L. Among them, the concentrated solution I was added to the macroporous adsorption resin HPD-300 column, the volume of the chromatographic medium was 170L, and the ratio of height to diameter was 8:1. 1.5 times the column volume per hour; then 6 times the column volume of 50% ethanol solution for elution, the flow rate is 1.5 times the column volume per hour, and the eluate is collected for future use.

[0056] The ethanol eluate was concentrated under reduced pressure at 55°C, and the concentrated vacuum was 0.6 MPa. The concentrated solution was vacuum-dried at 60°C, with a drying vacuum of 0.6 MPa, and the drying time was 24 hours, to obtain 5 kg of the phenyl...

Embodiment 2

[0061] Take desert cistanche 100kg, crush through a 10-mesh sieve, add 2m 3 70% ethanol solution, 20 DEG C under ultrasonic enhanced extraction (ultrasonic power is 3W / L) 60min, extract 1 time, extract liquid 500 order filter cloth filter, filtrate decompression concentrates, obtains concentrated liquid I altogether 340L. Among them, the concentrated solution I was added to the macroporous adsorption resin HPD-300 column, the volume of the chromatographic column medium was 170L, and the ratio of height to diameter was 8:1. It was eluted with deionized water 10 times the column volume, and the water eluate was collected at a flow rate of 1.5 times the column volume per hour, 6 times the column volume of 50% ethanol solution for elution, the flow rate is 1.5 times the column volume per hour, and the eluate is collected for future use.

[0062] The ethanol eluate was concentrated under reduced pressure at 70°C, and the concentrated vacuum was 0.6 MPa. The concentrated solution wa...

Embodiment 3

[0067] Take desert cistanche 100kg, crush through a 60-mesh sieve, add 0.8m 3 20% ethanol solution, 20 DEG C under ultrasonic enhanced extraction (ultrasonic power is 1000W) 60min, extract 3 times, extract liquid 500 order filter cloth filter, filtrate decompression concentrates, obtains concentrated solution I altogether 170L. Among them, the concentrated solution I is added to the macroporous adsorption resin HPD-300 column, the volume of the chromatography column medium is 170L, the ratio of height to diameter is 8:1, and it is eluted with deionized water of 10 times the column volume, and the flow rate is 0.2 times the column volume per hour. , collect the water eluate, elute with 50% ethanol solution of 6 times column volume, the flow rate is 0.2 times column volume per hour, collect the eluate for future use.

[0068] The ethanol eluate was concentrated under reduced pressure at 60°C, and the concentration vacuum was 0.7MPa; the concentrated solution was heated and dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com