A kind of nano-ceramic imitation paint and preparation method thereof

A porcelain-like coating and nanotechnology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of cold and heat resistance, salt spray resistance, water resistance, and poor life aging, and achieve the effect of enhanced water resistance and life aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

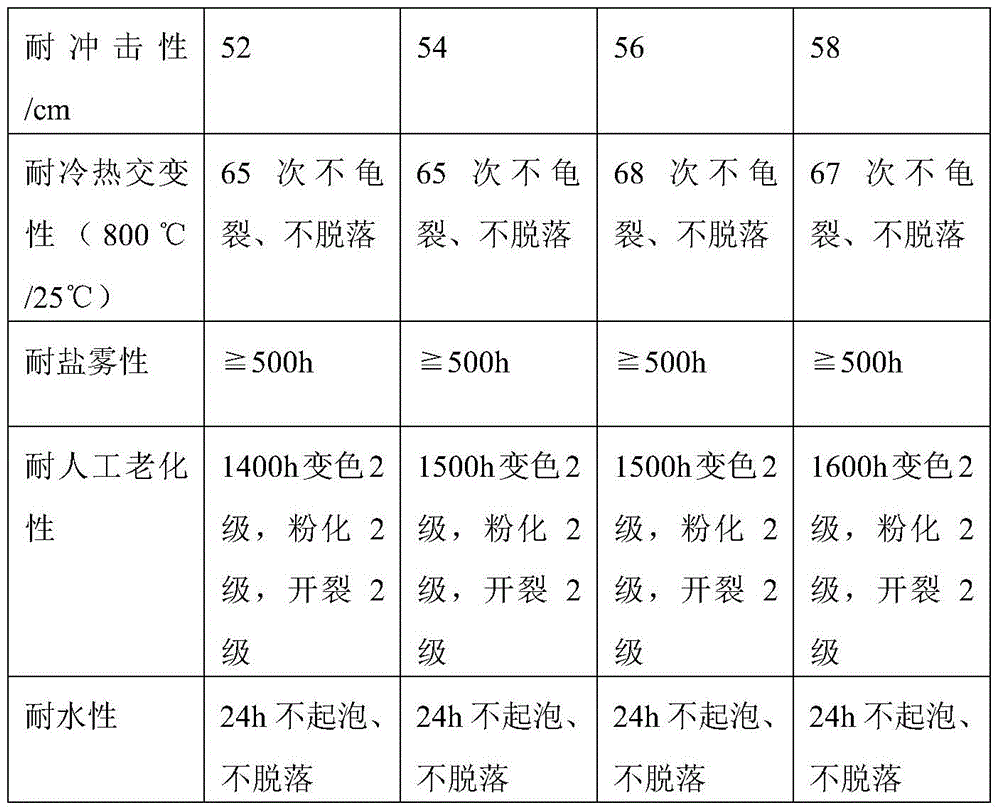

Examples

Embodiment 1

[0011] A kind of nano porcelain imitation paint, its preparation raw material is composed of the following components by weight percentage: 39 parts of nano titanium dioxide powder, 33 parts of nano calcium oxide powder, 25 parts of acrylic adhesive, 5 parts of citric acid, 9 parts of dioctyl phthalate 1 part, 1 part of nano-aluminum silicate powder, 2 parts of lignin, 0.1 part of ethylenediamine, 0.2 part of polyaluminum chloride, 0.2 part of defoamer, and 50 parts of water.

[0012] The preparation method of the above-mentioned nano-ceramic-like coating comprises the following steps: weighing the corresponding raw material components in parts by weight; putting the above-mentioned mixture into the reaction kettle at one time, starting the stirrer, Stir well for 3h~5h and discharge.

Embodiment 2

[0014] A kind of nano porcelain imitation paint, its preparation raw material is made up of following composition by weight percentage: 35 parts of nano titanium dioxide powder, 48 parts of nano calcium oxide powder, 35 parts of acrylic adhesive, 8 parts of citric acid, 12 parts of dioctyl phthalate 2 parts, 2 parts of nano-aluminum silicate powder, 5 parts of lignin, 0.2 part of ethylenediamine, 0.5 part of polyaluminum chloride, 0.4 part of defoamer, and 80 parts of water.

[0015] The preparation method of the above-mentioned nano-ceramic-like coating comprises the following steps: weighing the corresponding raw material components in parts by weight; putting the above-mentioned mixture into the reaction kettle at one time, starting the stirrer, Stir well for 3h~5h and discharge.

Embodiment 3

[0017] A kind of nano porcelain imitation paint, its preparation raw material is made up of following composition by weight percentage: Nano titanium dioxide 37 parts, nano calcium oxide powder 38 parts, acrylic adhesive 30 parts, citric acid 6 parts, dioctyl phthalate 11 parts 2 parts of nano-aluminum silicate powder, 4 parts of lignin, 0.1 part of ethylenediamine, 0.3 part of polyaluminum chloride, 0.4 part of defoamer, and 55 parts of water.

[0018] The preparation method of the above-mentioned nano-ceramic-like coating comprises the following steps: weighing the corresponding raw material components in parts by weight; putting the above-mentioned mixture into the reaction kettle at one time, starting the stirrer, Stir well for 3h~5h and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com