A kind of methanol gasoline rubber swelling inhibitor

A methanol-gasoline and rubber swelling technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as automobile metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

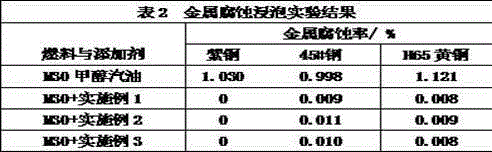

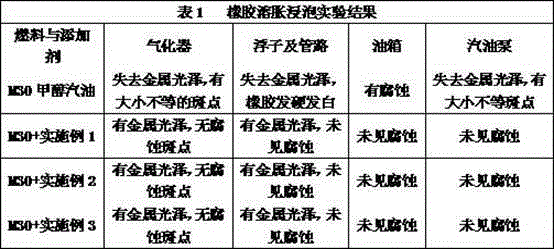

Examples

Embodiment 1

[0017] Take 12 kg of 2-mercaptobenzothiazole, 8 kg of iodopropynyl n-butylcarbamate, 1 kg of butyl hydroxyanisole, 16 kg of 2,6-di-tert-butyl p-cresol; Sodium 8 kg, 2-ethylimidazole 13 kg, cyclooctadiene ruthenium dichloride 6 kg, p-methoxypropiophenone 9 kg, polyisobutylene succinimide 2 kg, tert-butyldimethylsilyl chloride 3 kg, 12 kg of methyl tert-butyl ether. Add it to the reaction kettle in sequence, and react under closed stirring at 55-58°C for 60-80 minutes, and then it is ready after cooling.

Embodiment 2

[0019] Take 12 kg of 2-mercaptobenzothiazole, 6 kg of iodopropynyl n-butylcarbamate, 1 kg of butyl hydroxyanisole, 15 kg of 2,6-di-tert-butyl p-cresol; Sodium 7 kg, 2-ethylimidazole 12 kg, cyclooctadiene ruthenium dichloride 6 kg, p-methoxypropiophenone 8 kg, polyisobutylene succinimide 2 kg, tert-butyldimethylsilyl chloride 3 kg, 12 kg of methyl tert-butyl ether. Add it to the reaction kettle in sequence, and react under closed stirring at 55-58°C for 60-80 minutes, and then it is ready after cooling.

Embodiment 3

[0021] Take 13 kg of 2-mercaptobenzothiazole, 9 kg of iodopropynyl n-butylcarbamate, 2 kg of butyl hydroxyanisole, 18 kg of 2,6-di-tert-butyl p-cresol; Sodium 10 kg, 2-ethylimidazole 15 kg, cyclooctadiene ruthenium dichloride 9 kg, p-methoxypropiophenone 12 kg, polyisobutylene succinimide 3 kg, tert-butyldimethylsilyl chloride 4 kg, 13 kg of methyl tert-butyl ether. Add it to the reaction kettle in sequence, and react under closed stirring at 55-58°C for 60-80 minutes, and then it is ready after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com