Semi-continuous culture method for spores recovered from cordyceps sinensis fermentation liquor

A technology of Cordyceps sinensis and a cultivation method, applied in the field of Cordyceps sinensis fermentation and cultivation, can solve the problems of no research on the cultivation cycle of Cordyceps sinensis, high cost of cultivation of Cordyceps sinensis, unsatisfactory effect, etc., and achieve the advantages of shortening the adaptation time, reducing the amount of sewage treatment and improving the market value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

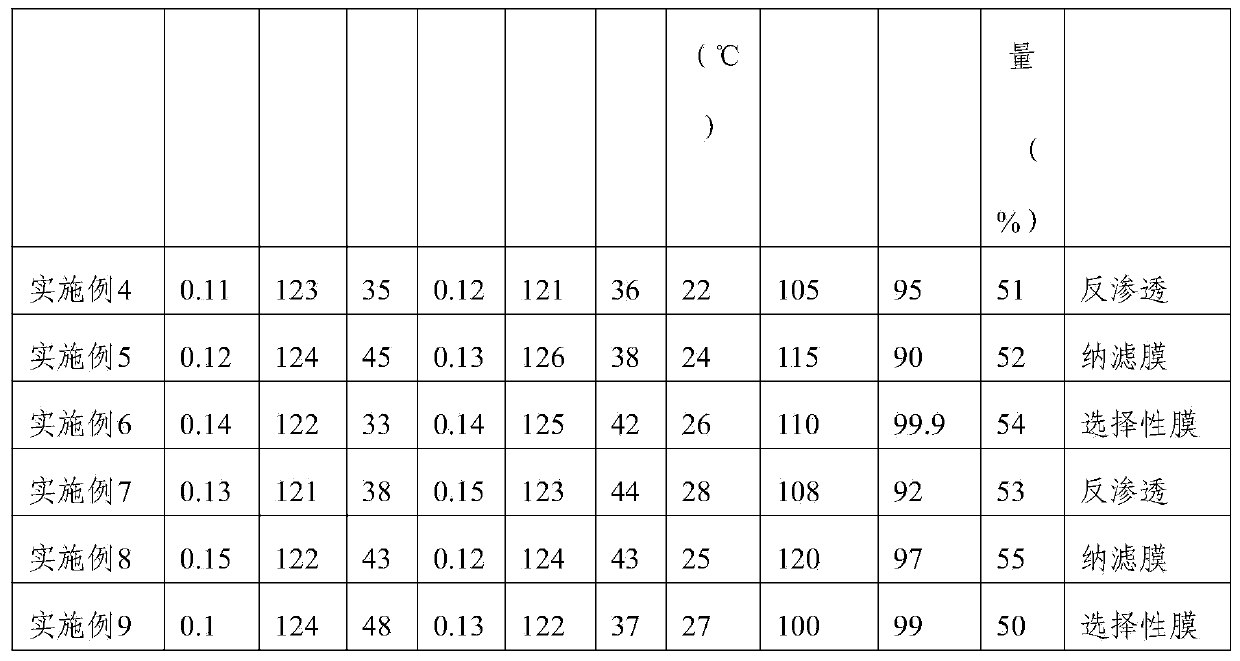

[0031] Select the fermentation system as 5m 3 As a semi-continuous fermentation and cultivation system for Cordyceps sinensis, use purified steam to sterilize empty tanks, pipes, filters and valves at a pressure of 0.1 MPa and a temperature of 121°C for 50 minutes; and connect empty tanks, pipes, filters and valves; Put the culture medium consisting of 2.0% glucose, 4.0% peptone, 0.20% KH2PO4, 0.10% MgSO4, 0.15% corn steep liquor, 0.25% molasses, and the rest into the empty tank, and the filling amount is the volume capacity of the empty tank 50%, and sterilized at a pressure of 0.12MPa and a temperature of 121°C for 45 minutes; then, replace the sterile air to maintain the pressure, start the cold water circulation system to cool down to 20°C, and inoculate the fermentation culture; when the fermentation lasts 100 hours , the fermentation tank is sampled, and the fermentation liquid is detected. When the conidia reach 90% of the exfoliated parent sporozoites, and the number o...

Embodiment 2

[0033] Select the fermentation system as 5m 3 As a semi-continuous fermentation culture system for Cordyceps sinensis, use purified steam to sterilize empty tanks, pipes, filters and valves at a pressure of 0.15MPa and a temperature of 124°C for 30 minutes; and connect empty tanks, pipes, filters and valves; Put the culture medium consisting of 2.0% glucose, 4.0% peptone, 0.20% KH2PO4, 0.10% MgSO4, 0.15% corn steep liquor, 0.25% molasses, and the rest into the empty tank, and the filling amount is the volume capacity of the empty tank 55%, and sterilized at a pressure of 0.15MPa and a temperature of 126°C for 35 minutes; then, replace the sterile air to maintain the pressure, start the cold water circulation system to cool down to 30°C, and inoculate the fermentation culture; when the fermentation lasts for 120 hours , the fermentation tank is sampled, and the fermented liquid is detected. When the conidia reach 99.9% of the exfoliated parent sporozoites, and the sporozoites i...

Embodiment 3

[0035]Select a fermentation system of 5m3 as the semi-continuous fermentation and cultivation system of Cordyceps sinensis, use purified steam to sterilize the empty tanks, pipelines, filters and valves at a pressure of 0.13MPa and a temperature of 123°C for 40min; And the valve is connected; put the culture medium composed of 2.0% glucose, 4.0% peptone, 0.20% KH2PO4, 0.10% MgSO4, 0.15% corn steep liquor, 0.25% molasses and the rest into the empty tank. It is 53% of the volume capacity of the empty tank, and it is sterilized for 40 minutes at a pressure of 0.12MPa and a temperature of 123°C; then, replace the sterile air to maintain the pressure, start the cold water circulation system to cool down to 25°C, and then inoculate and ferment; After the fermentation was carried out for 110 hours, the fermenter was sampled, and the fermented liquid was detected. When the conidia reached 95% of the exfoliated parent spore spores and the increase in the number of spores was not obvious...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com