Purification and Utilization System and Technology of Gas Equalization and Release in Blast Furnace Top Tank

A technology for releasing coal gas and blast furnace furnace, which is applied in the directions of blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems of not proposing better solutions, reducing the value of recovered gas, reducing the calorific value of gas, etc., and achieves high recovery and utilization efficiency. The effect of compact layout and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

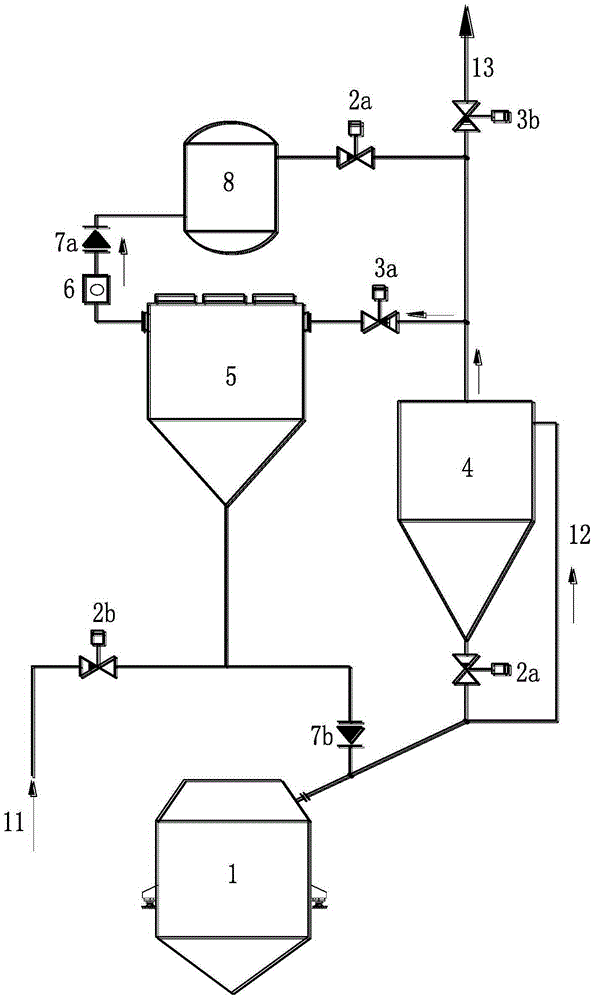

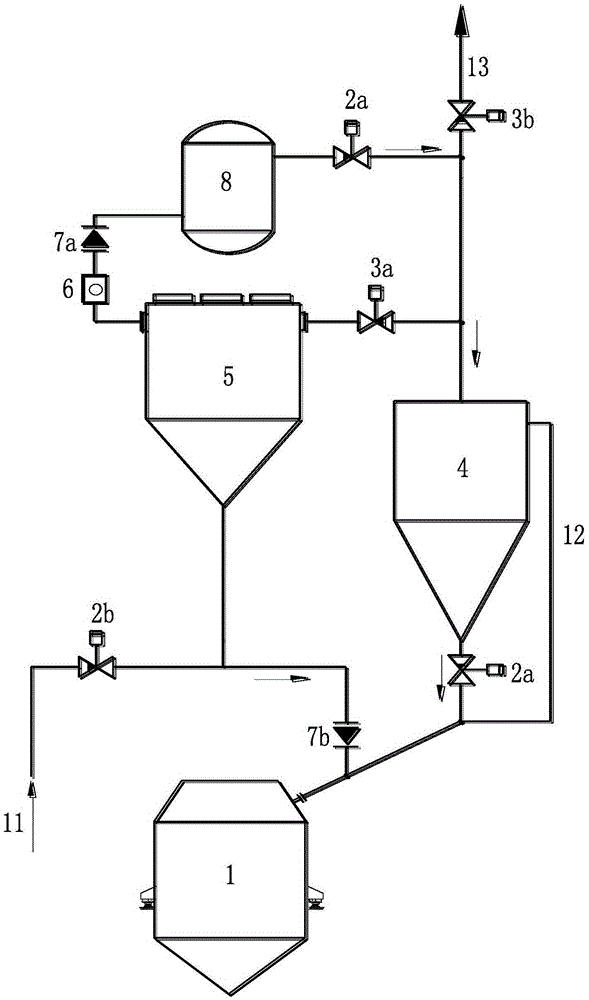

[0036] Such as Figure 1-2 As shown, in this embodiment, the gas purification and utilization system for blast furnace top material tank pressure equalization and release includes a purification device, a pressurization device connected to the purification device, and a pressure equalization device, wherein,

[0037] The purification device includes a cyclone dust collector 4 connected to the material tank 1 and a bag filter 5 connected to the cyclone dust collector 4, and the material tank 1 is connected to the lower part of the cyclone dust collector 4 through the first equalizing pipeline. The outlet is connected, and the upper outlet of the cyclone dust collector 4 is connected with the inlet of the bag dust collector 5 .

[0038] The pressurizing device includes a gas pressurizing device 6 connected to the bag filter 5 and a gas storage tank 8 connected to the gas pressurizing device 6, the outlet of the bag filter 5 is connected to the gas pressurizing device 8, The gas...

Embodiment 2

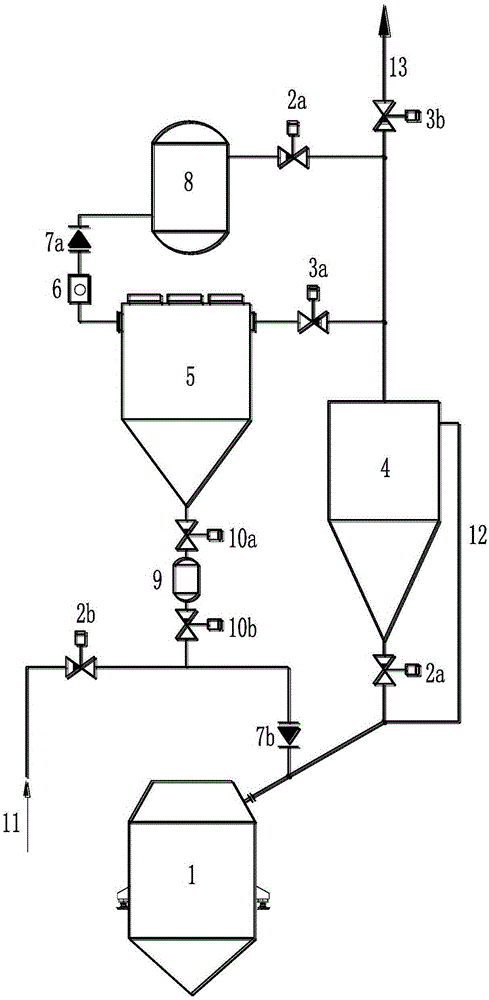

[0058] Such as image 3 As shown, on the basis of Example 1, the blast furnace roof tank in the present embodiment is pressure-equalized and diffused gas purification and utilization system, and the dust discharge pipeline is connected to the place where the dust discharge port of the bag filter 5 is collected. The ash storage tank 9 for dust, the first ash discharge valve 10a and the second ash discharge valve 10b are respectively connected to the ash inlet and the ash discharge port of the ash storage tank 9 . When pressurizing the material tank 1 by the nitrogen gas of the secondary equalization, it can be used as the delivery of the dedusting dust in the ash storage tank 9, and the specific process is: when the gas dust in the ash storage tank 9 is stored to When a certain amount of ash needs to be discharged, the first ash discharge valve 10a is closed, and after the secondary pressure equalizing valve 2b is opened, the second ash discharge valve 10b is opened for ash dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com