Novel anti-liquid leakage zinc air battery for carbonation self-test

A zinc-air battery, anti-leakage technology, applied in hybrid battery parts, fuel cell parts, fuel cell-type half-cells and primary-cell-type half-cells, etc., can solve problems such as battery failure and achieve Invalidation, prolonging the storage period, and improving the effect of the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

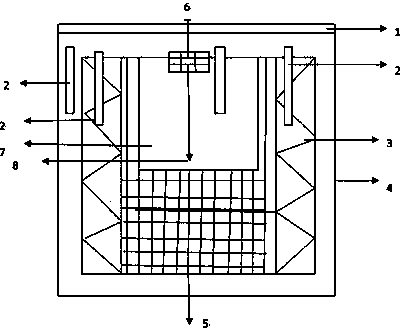

[0026] A zinc-air battery, comprising an air positive electrode 3 and a battery case 4, characterized in that: the air positive electrode has a protruding portion in contact with the inside of the battery case, and the gap between the air electrode and the battery case forms an air flow Road, the air electrode is a wave shape composed of multiple units, wherein, the interface of the unit wave is one or more of rectangle, trapezoid, semicircle, ellipse, and the air electrode with wave structure increases the catalytic efficiency. The reaction area is convenient for current discharge.

[0027] The preparation method of air cathode 3:

[0028] Step 1: Make the nickel foam collector net into a wave shape;

[0029] Step 2: Coat the collector net with a catalytic layer, and the other side with a waterproof and breathable layer;

[0030] Step 3: Coat the catalytic layer with a (molded) waterproof and breathable layer, or place two PTFE waterproof and breathable membranes on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com