Method for preparing calcium silicate thermal insulation material

A thermal insulation material, calcium silicate technology, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve pollution and other problems, and achieve the effect of strong operability, easy control, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

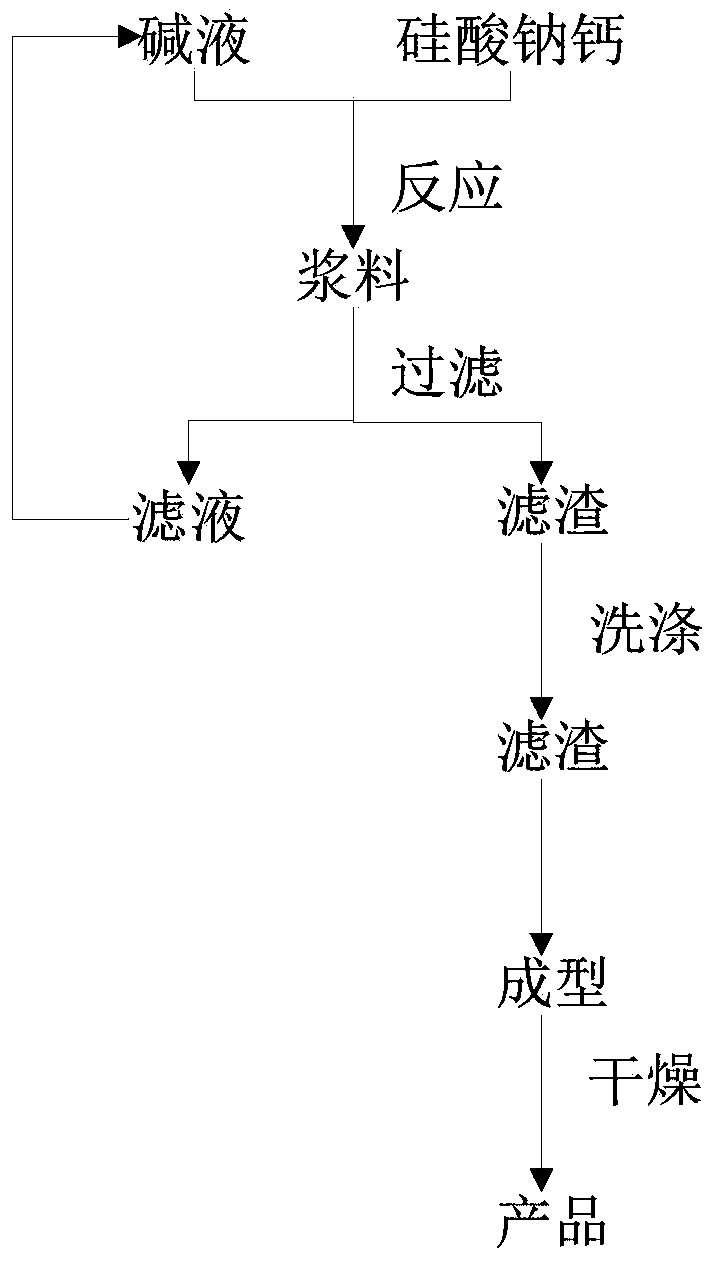

Method used

Image

Examples

Embodiment 1

[0019] The raw material of this example is solid slag with sodium calcium silicate as the main component obtained by chemical conversion of fly ash, and its main component is 19.13% Na 2 O, 30.67% SiO 2 and 34.91% CaO, the main component is sodium calcium silicate (NaCaHSiO 4 ). Mix the above solid slag with dilute lye, the mass ratio of the two is 1:30, Na in the dilute lye 2 The O concentration meter is 0.1g / L; after mixing, the slurry is decomposed in the reactor, the reaction temperature is 170°C, the reaction time is 4h, and vacuum filtration is carried out after the reaction; Molding, the molding pressure is maintained at 0.2MPa; finally, the molded product is dried at 100°C for 3 hours, and the bulk density of the molded material is 209kg / m 3 .

Embodiment 2

[0021] Select the solid slag among the embodiment 1 equally as raw material, main component is 19.13% Na 2 O, 30.67% SiO 2 and 34.91% CaO, mainly in the form of sodium calcium silicate (NaCaHSiO 4 ). Mix the above solid slag with dilute lye, the mass ratio of the two is 1:5, Na in the dilute lye 2 The O concentration meter is 40g / L; after mixing, the slurry is decomposed in the reactor, the reaction temperature is 90°C, the reaction time is 20h, vacuum filtration is carried out after the reaction; the slag phase obtained after the suction filtration is formed by a selected mold , the molding pressure was maintained at 0.2MPa; finally, the molded product was dried at 150°C for 2 hours, and the bulk density of the molding material was 617kg / m 3 .

Embodiment 3

[0023] Select the solid slag among the embodiment 1 equally as raw material, main component is 19.13% Na 2 O, 30.67% SiO 2 and 34.91% CaO, mainly in the form of sodium calcium silicate (NaCaHSiO 4 ). Mix the above solid slag with dilute lye, the mass ratio of the two is 1:20, Na in the dilute lye 2 The O concentration meter is 40g / L; after mixing, the slurry is decomposed in the reactor, the reaction temperature is 260°C, the reaction time is 2h, vacuum filtration is carried out after the reaction; the slag phase obtained after the suction filtration is formed by a selected mold , the molding pressure is maintained at 0.2MPa; finally, the molded product is dried at 120°C for 2 hours, and the bulk density of the molding material is 286kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com