Thiol ester acid and preparation method and application thereof

A mercapto acid and esterification technology, which is applied in the field of preparing thermoreversible ion-crosslinked polyvinyl chloride, can solve problems such as difficult industrialization, and achieve the effects of avoiding the precipitation of additives, inhibiting coloring and degradation, and achieving good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

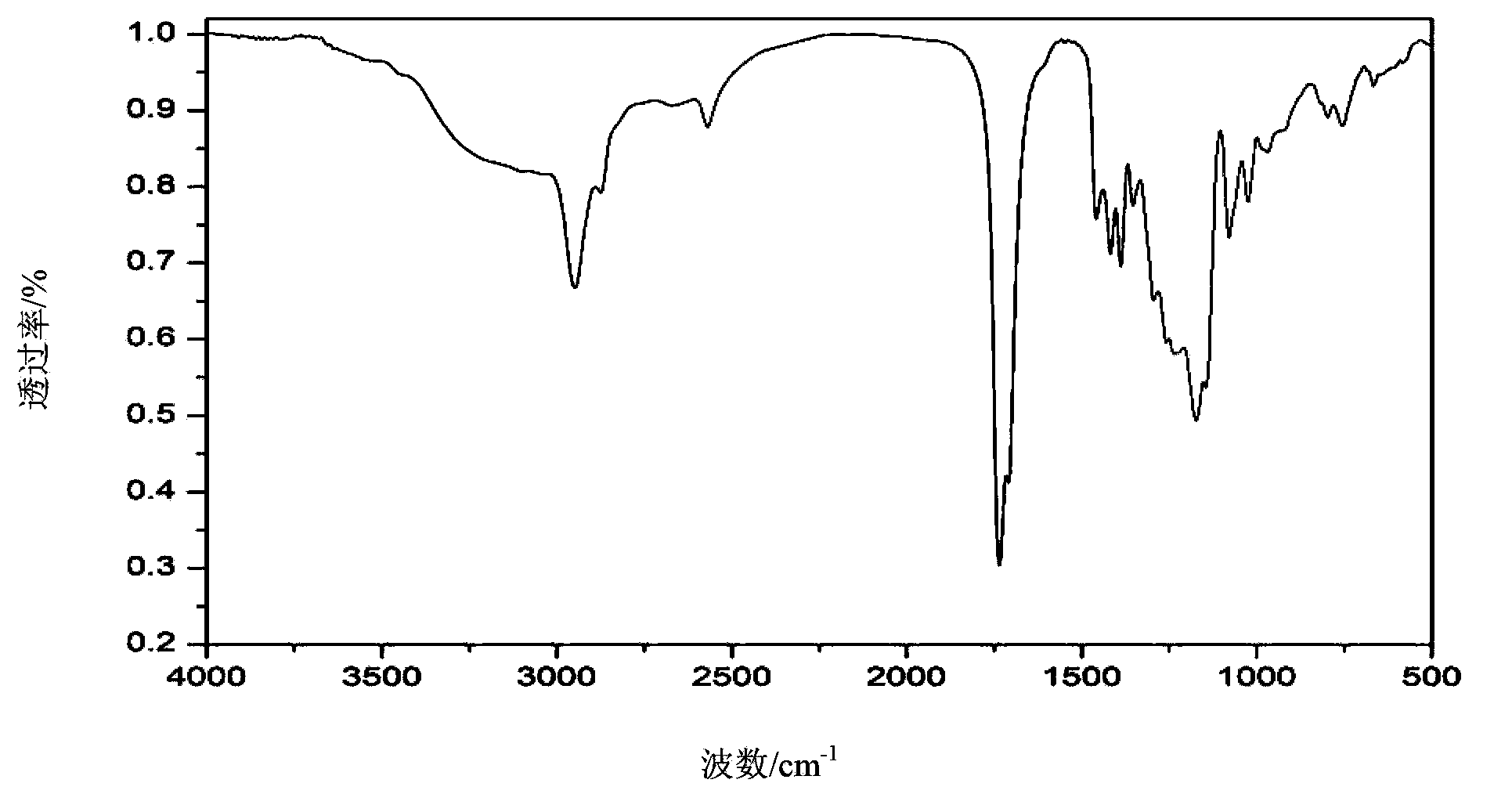

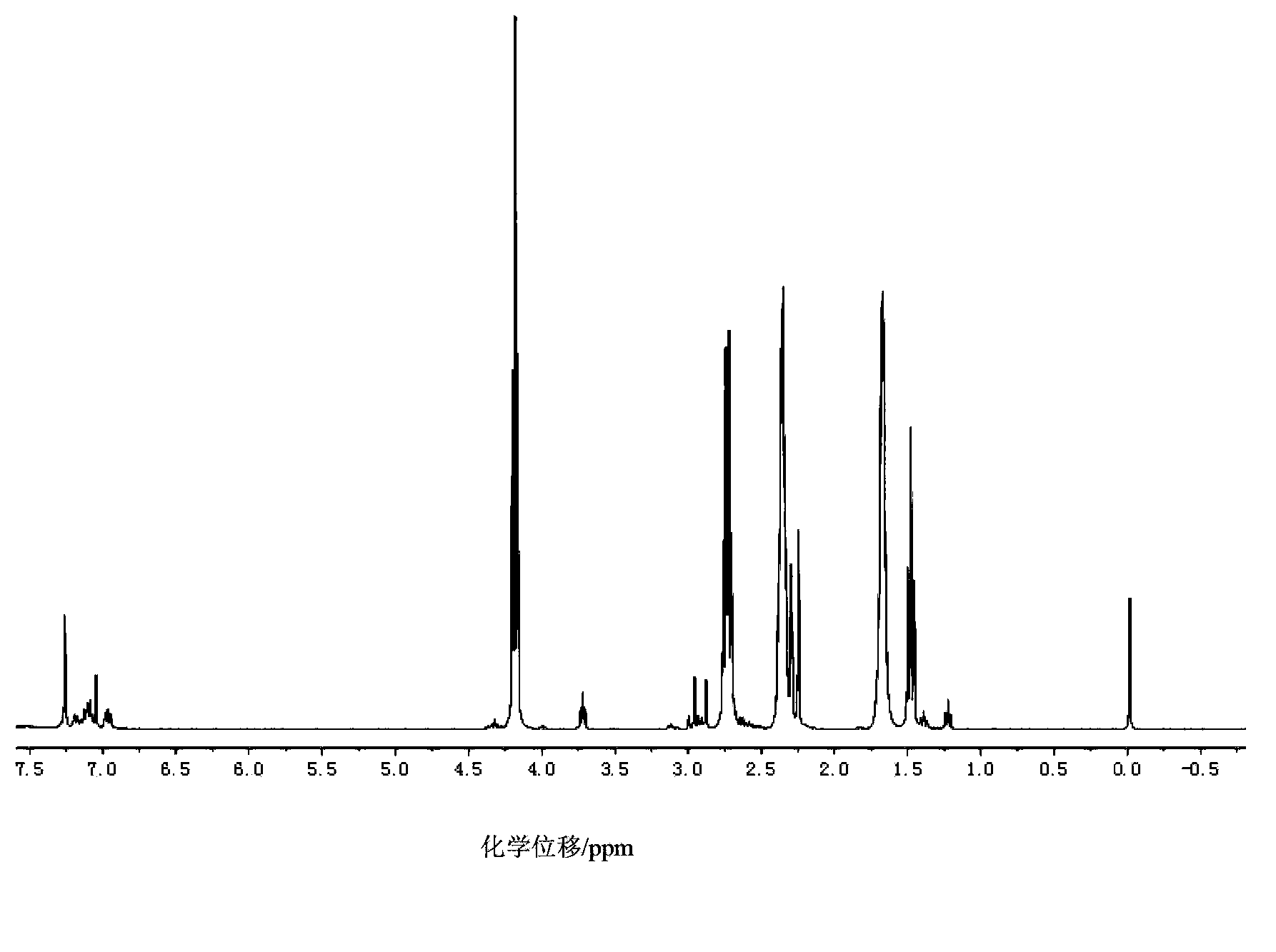

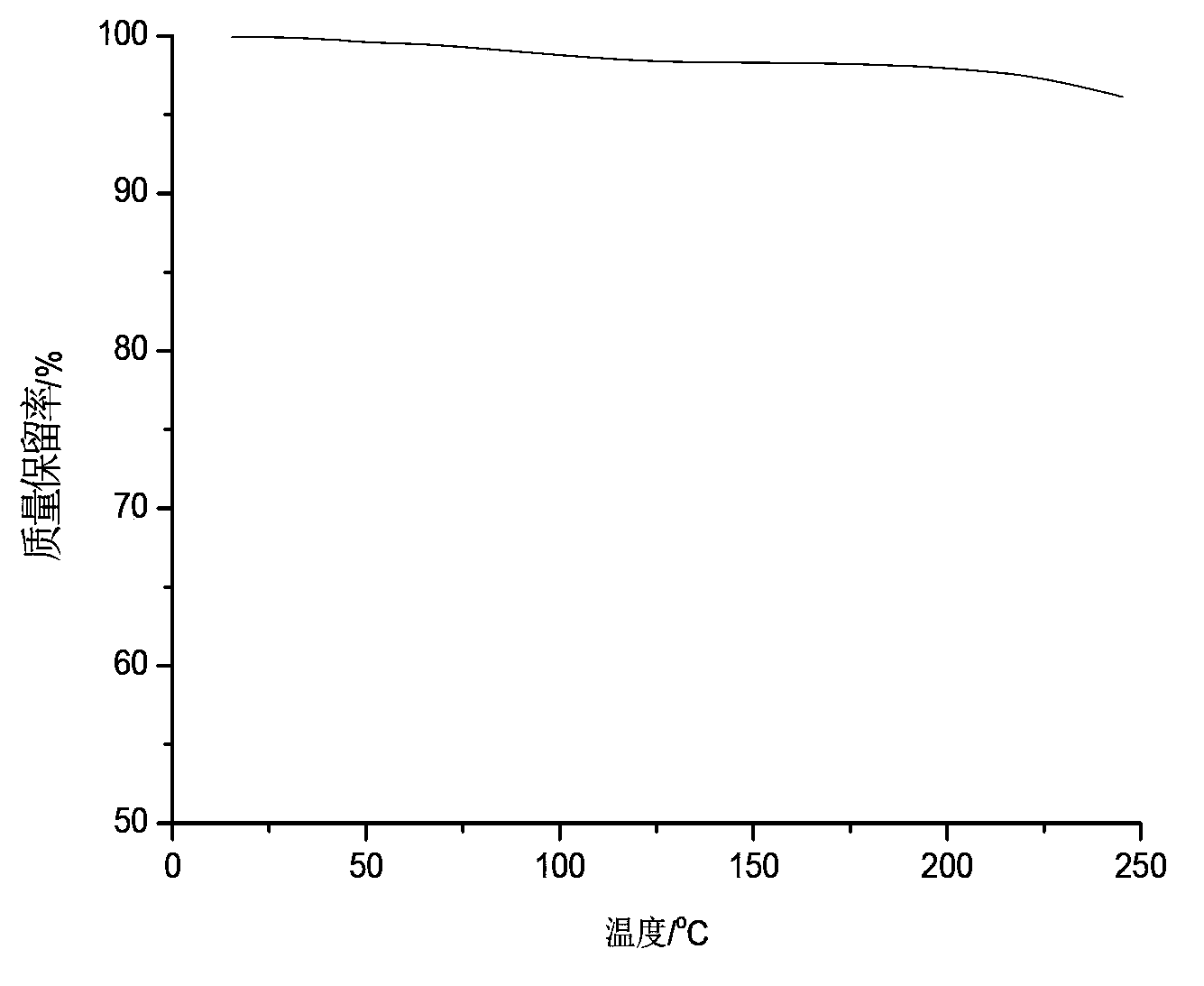

Embodiment 1

[0061] Under the protection of oxygen-free and high-purity nitrogen (purity ≥ 99.999%), mix 117 grams of adipic acid (analytical grade), 70 grams of mercaptoethanol (analytic grade) and 200 grams of xylene (analytic grade) and stir , and then gradually heated the temperature from room temperature to 130°C; after the adipic acid was melted and dissolved, a solution prepared by 1 gram of p-toluenesulfonic acid (analytical pure) and 50 grams of toluene was added dropwise, under oxygen-free and high-purity nitrogen atmosphere Under protection, the esterification reaction was carried out at a temperature of 130° C. for 6 hours, and at the same time, the water generated by the reaction was received in the water separator. After the product is cooled for several hours, remove the sediment, take the upper layer solution and evaporate toluene and xylene under reduced pressure to obtain 148 grams of colorless, transparent and viscous mercaptoesteric acid; add 10 grams of anhydrous Magne...

Embodiment 2

[0067] 100 grams of DOP and 50 grams of light magnesium oxide are added to an emulsifier, and ground into a slurry at room temperature; two parts of each 13.5 grams of the above-mentioned grinding slurry are respectively added at room temperature. 1 prepare the mercaptoesteric acid, then add 1 gram and 21 grams of DOP and mix respectively to obtain composite slurry (the total content of DOP in the two kinds of composite slurry is respectively 10 grams and 30 grams); then to the composite slurry Add 100 grams of polyvinyl chloride resin with a degree of polymerization of 1000 in each material, knead with a high-speed mixer at 25 ° C, and obtain a polyvinyl chloride dry mixture after cooling; the obtained polyvinyl chloride dry mixture is passed through a double-roller open mill Molded for 5 minutes, the temperature during mastication was 150°C, and two 0.8mm-thick samples with different DOP amounts were obtained, and then the three-layer samples were stacked under a single-layer...

Embodiment 3

[0072] Get 13.5 grams of grinding slurry in Example 2, add 4.5 grams of mercaptoesteric acid prepared in Example 1 and 1 gram of DOP at room temperature and stir and mix, then add 100 grams of polyvinyl chloride resin with a degree of polymerization of 1000, at 25 ° C Knead with a high-speed mixer and cool to obtain a polyvinyl chloride dry mix; the obtained polyvinyl chloride dry mix is masticated by a double-roller mill for 5 minutes to obtain a sample. The temperature during mastication is 170 ° C, and then three layers The samples were stacked under a single-layer electric tablet press at 180°C, and hot-pressed at a temperature of 180°C for 10 minutes to make a 2mm thick thermoreversible ion-crosslinked polyvinyl chloride sample. The appearance of the sample can be seen Figure 4 C in

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com