Polyurethane resin for hydrolysis-resistant film nubuck and preparation method of polyurethane resin

A polyurethane resin, hydrolysis-resistant technology, applied in textiles and papermaking, etc., can solve the problems of poor hydrolysis resistance, difficult to meet the requirements of high hydrolysis resistance of nubuck leather, and achieve high hydrolysis resistance, good color development, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In a heatable reaction vessel equipped with a distillation column and a conical distillation receiver, add 10.48kg of adipic acid, 1.19kg of phthalic anhydride and 8.33kg of neopentyl glycol, turn on the stirring device and nitrogen atmosphere protection After the installation, the temperature was raised to 140°C, and the product water was removed by distillation during the reaction. At this time, the acid value was measured to be about 35 mgKOH / g. Then add 2.0g of catalyst tetraisopropyl titanate TIPT, reduce the pressure to 10-15mbar, raise the temperature to about 180°C, continue the polycondensation reaction, and remove the product water by distillation during the reaction process. Measure the hydroxyl value and acid value of the mixture in the reaction vessel. When the hydroxyl value reaches 56.1mgKOH / g and the acid value reaches about 0.35mgKOH / g, cool the reaction vessel, lower the temperature to room temperature, and terminate the reaction to obtain polyadipate o...

Embodiment 2

[0042] In a heatable reaction vessel equipped with a distillation tower and a conical distillation receiver, add 10.66kg of adipic acid, 1.20kg of phthalic anhydride and 8.14kg of neopentyl glycol, turn on the stirring device and nitrogen atmosphere protection After the installation, the temperature was raised to 160°C, and the product water was removed by distillation during the reaction. At this time, the acid value was measured to be about 38 mgKOH / g. Then add 2.2g of catalyst tetraisopropyl titanate TIPT, lower the pressure to 10-15mbar, raise the temperature to about 220°C, continue the polycondensation reaction, and remove the product water by distillation during the reaction process. Measure the hydroxyl value and acid value of the mixture in the reaction vessel. When the hydroxyl value reaches 37.4mgKOH / g and the acid value reaches about 0.38mgKOH / g, cool the reaction vessel, lower the temperature to room temperature, and terminate the reaction to obtain polyadipate ort...

Embodiment 3

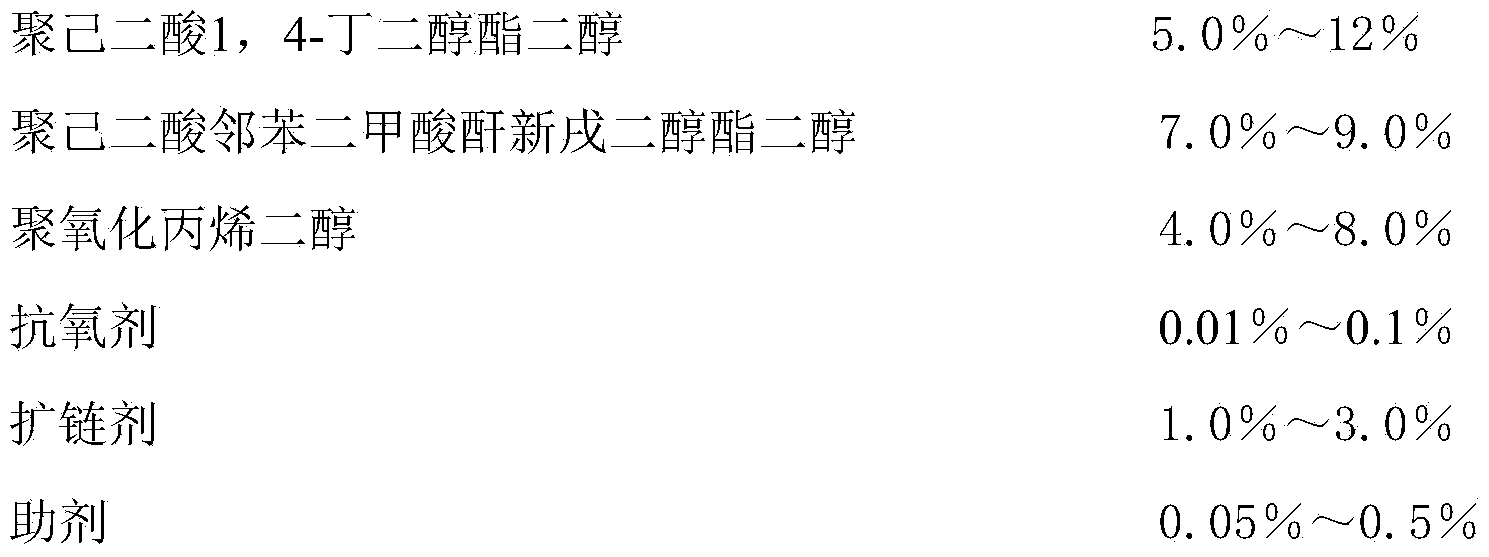

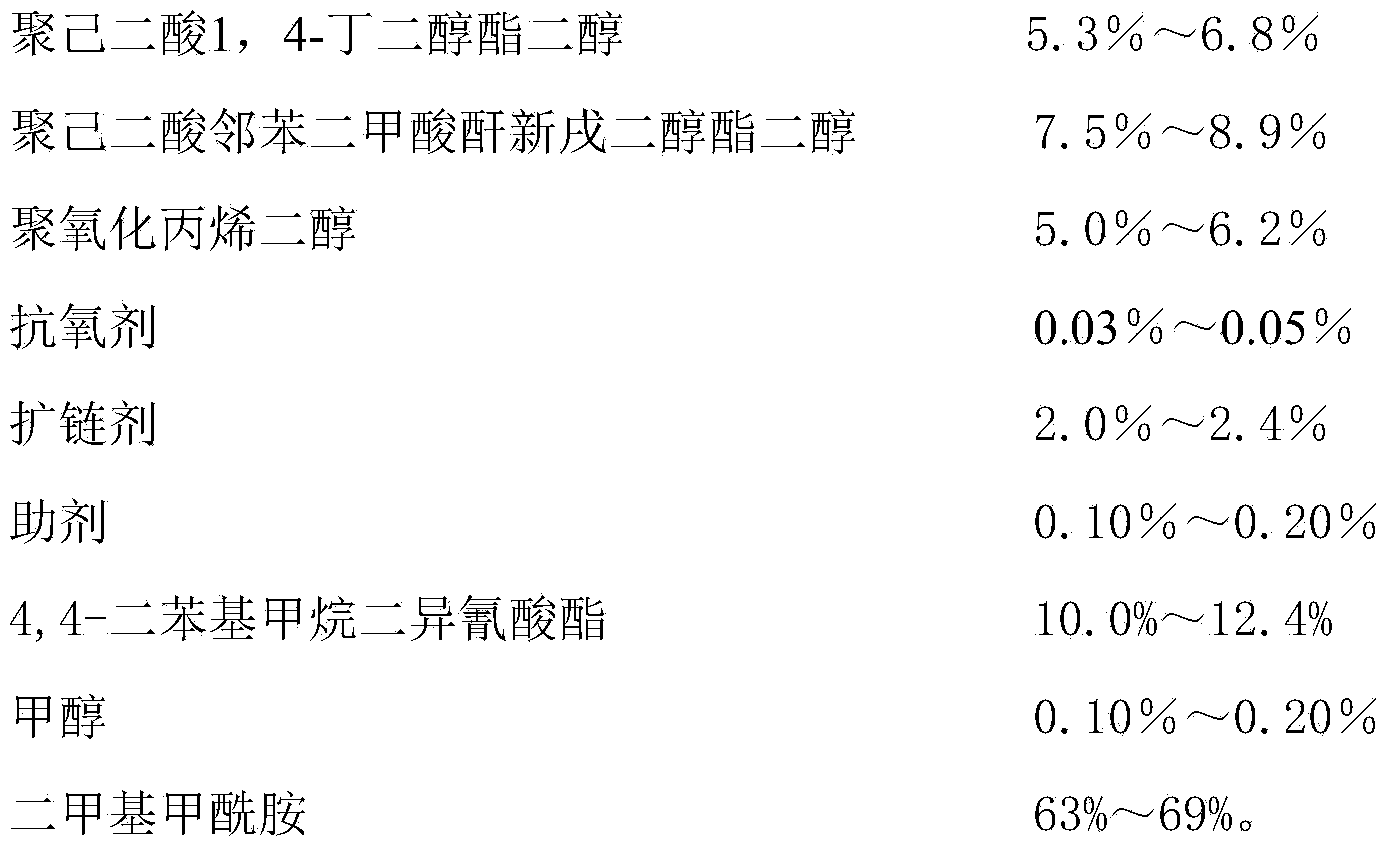

[0044]

[0045] First, polyadipate 1,4-butylene glycol ester diol, polyadipate phthalic anhydride neopentyl glycol ester diol, antioxidant, 1.66kg of diisocyanate and 13.77kg of dimethyl formamide, the reaction temperature is 70°C, and the reaction time is 1.0 to 1.5 hours to obtain a prepolymer;

[0046] Add 6.89 kg of dimethylformamide and polyoxypropylene diol to the prepolymer, stir for 40 minutes, add 0.45 kg of diisocyanate to react, the reaction temperature is 70 ° C, and the reaction time is 1.5 hours to obtain the prepolymer ;

[0047] Add 17.22 kg of dimethylformamide and chain extender to the prepolymer, stir for 40 minutes, add the remaining diisocyanate to react, the reaction temperature is 70°C, and the reaction time is 4.0 hours;

[0048] After adding the remaining dimethylformamide and methanol to react for 15 minutes, polycarbodiimide was added to obtain the polyurethane resin for hydrolysis-resistant film nubuck leather.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com