Method for preparing water swelling rubber with good weather resistance

A technology of water-absorbing swelling rubber and weather resistance, which is applied in the field of preparation of water-absorbing swelling rubber, can solve the problems of low water-absorbing expansion ratio, poor elasticity of the rubber body, cumbersome process, etc., and achieve good water absorption performance and excellent weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

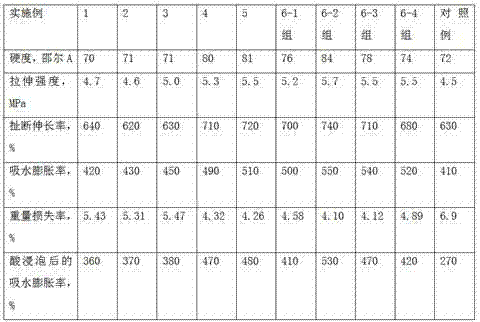

Examples

Embodiment 1

[0032] Step 1, take 30Kg of nitrile rubber, after pulverization, inject C ions into the nitrile rubber with an ion implanter to obtain modified nitrile rubber; the amount of C ions is 1Kg; the ion energy is 20keV; the beam density range is 0.5mA / cm 2 ; The ion source adopted is graphite with a purity of 99%;

[0033] The 2nd step, the modified acrylonitrile-butadiene rubber obtained in the 1st step is mixed with sodium polyacrylate 3Kg, chlorinated polypropylene (28% chlorine content) 4Kg, is evenly milled with an open mill, and the roll distance of the open mill is 2 mm, time 3min;

[0034] The 3rd step, add polyvinylpyrrolidone 2Kg, carbon black 2Kg and white carbon black 1Kg again, open mill evenly, the roller distance of open mill is 2 mm, time 8min;

[0035] In the 4th step, add vulcanization accelerator M 1Kg again, open mill evenly, the roller distance of open mill is 0.4 mm, time 3min, next sheet, leave standstill, standby;

[0036] Step 5: Sulfurize in a flat vul...

Embodiment 2

[0039] The first step, take 50Kg of nitrile rubber, after crushing, inject C ions to the nitrile rubber with an ion implanter to obtain modified nitrile rubber; the amount of C ions is 3Kg; the ion energy is 30keV; the beam density range is 0.8mA / cm 2 ; The ion source adopted is graphite with a purity of 99%;

[0040] The 2nd step, the modified acrylonitrile-butadiene rubber obtained in the 1st step is mixed with sodium polyacrylate 5Kg, chlorinated polypropylene (chlorine content 28%) 6Kg, mixes evenly with open mill, and the roll distance of open mill is 2 mm, time 5min;

[0041] The 3rd step, add polyvinylpyrrolidone 4Kg, carbon black 4Kg and white carbon black 3Kg again, open mill evenly, the roller distance of open mill is 2 mm, time 12min;

[0042] In the 4th step, add vulcanization accelerator M 2Kg again, open mill evenly, the roller distance of open mill is 0.4 mm, time 5min, the next sheet, leave standstill, for subsequent use;

[0043] Step 5: Sulfurize in a fl...

Embodiment 3

[0046] The first step, take 40Kg of nitrile rubber, after pulverization, inject C ions to the nitrile rubber with an ion implanter to obtain modified nitrile rubber; the amount of C ions is 2Kg; the ion energy is 25keV; the beam density range is 0.6 mA / cm 2 ; The ion source adopted is graphite with a purity of 99%;

[0047] The 2nd step, the modified acrylonitrile-butadiene rubber obtained in the 1st step is mixed with sodium polyacrylate 4Kg, chlorinated polypropylene (chlorine content 28%) 5Kg, mixes evenly with open mill, and the roll distance of open mill is 2 mm, time 4min;

[0048] The 3rd step, add polyvinylpyrrolidone 3Kg, carbon black 3Kg and white carbon black 2Kg again, open mill evenly, the roller pitch of open mill is 2 mm, time 10min;

[0049] The 4th step, add vulcanization accelerator M 2Kg again, open mill evenly, the roller distance of open mill is 0.4 mm, time 4min, next sheet, leave standstill, standby;

[0050] Step 5: Sulfurize in a flat vulcanizer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com