Three-dimensional figure detecting device and measuring method

A technology of three-dimensional graphics and detection devices, which is applied to measurement devices, optical devices, instruments, etc., can solve problems such as low utilization of light energy, save equipment costs, improve detection efficiency, and simplify solution methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

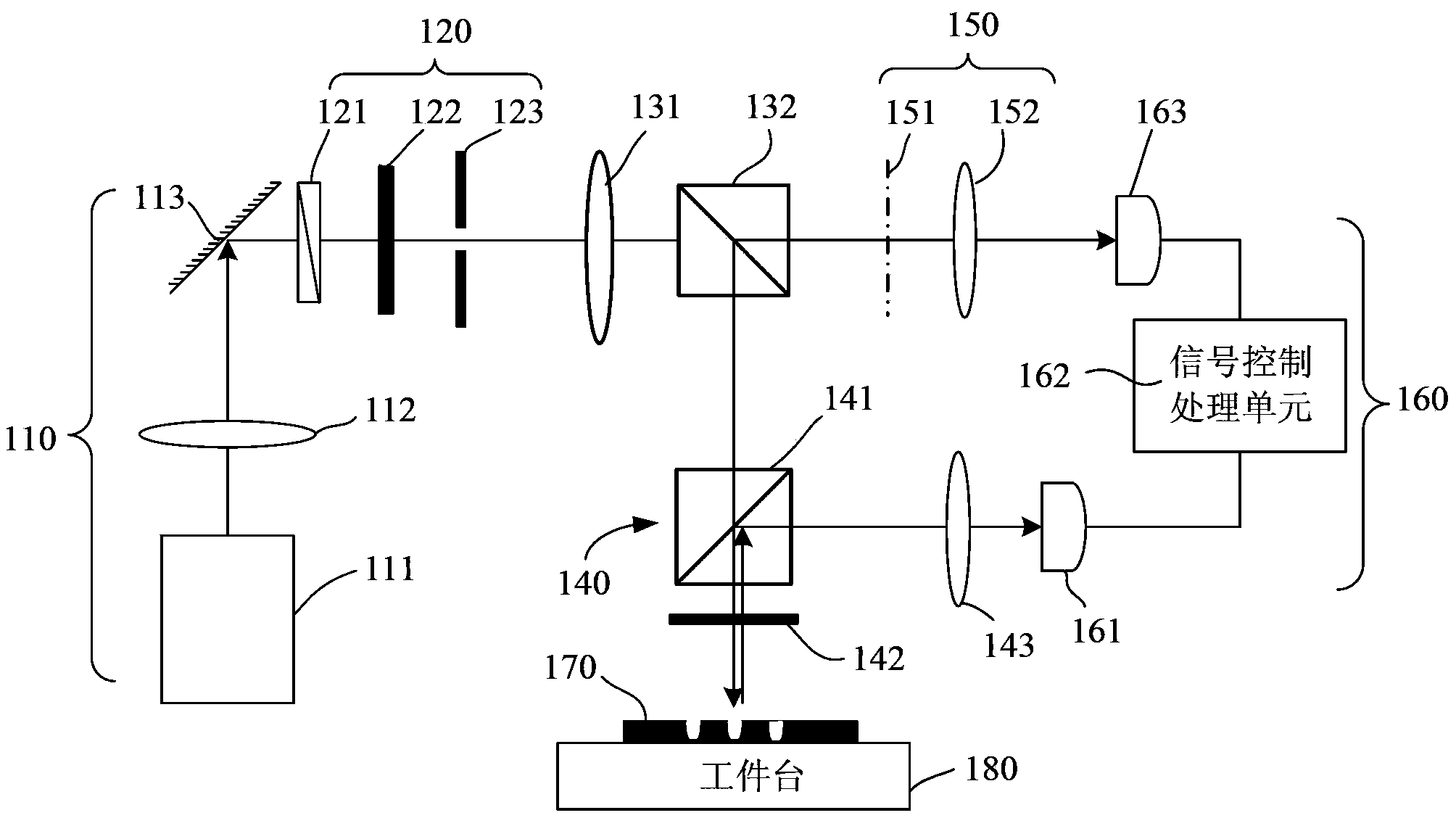

[0066] Please refer to figure 1 , the three-dimensional pattern detection device provided in this embodiment is used to detect the sample 150 to be tested, which includes:

[0067] an illumination projection module 110, configured to generate a detection beam and a reference beam, and project the detection beam onto the surface of the sample to be measured 150;

[0068] The reference imaging module 120 includes a reference plane 121, the reference imaging module 120 is used to collect the reference beam projected onto the reference plane 121 to generate a reference light intensity distribution signal;

[0069] The detection imaging module 130 is used to collect the reflected and diffracted light on the surface of the sample 150 to be tested to generate a detection light intensity distribution signal; and

[0070] The control processing module 140 is configured to perform an intensity correlation operation on the light intensity distribution signal of the probe light and the l...

Embodiment 2

[0104] The difference between this embodiment and Embodiment 1 is that the illumination light sources used in this embodiment are different, and the corresponding optical modulation components are also different.

[0105] Please refer to Figure 8 , in this embodiment, the illumination light source 210 uses multiple lasers 211 with different wavelengths, for example, the wavelengths are λ 1 , lambda 2 , lambda 3 lasers 211, and the laser beams generated by the multiple lasers 211 enter the optical modulation component 220 through a single-mode polarization-maintaining fiber 212 and a multiplexer 213. Further, the optical modulation component 220 includes a beam expander 221 , a rotating glass 222 , a polarizer 223 and a lens 224 sequentially arranged along the light propagation direction for beam shaping of the light emitted by the illumination source 210 . Preferably, the rotation of the rotating glass 222 is controlled by a motor 225 .

[0106] Specifically, the laser be...

Embodiment 3

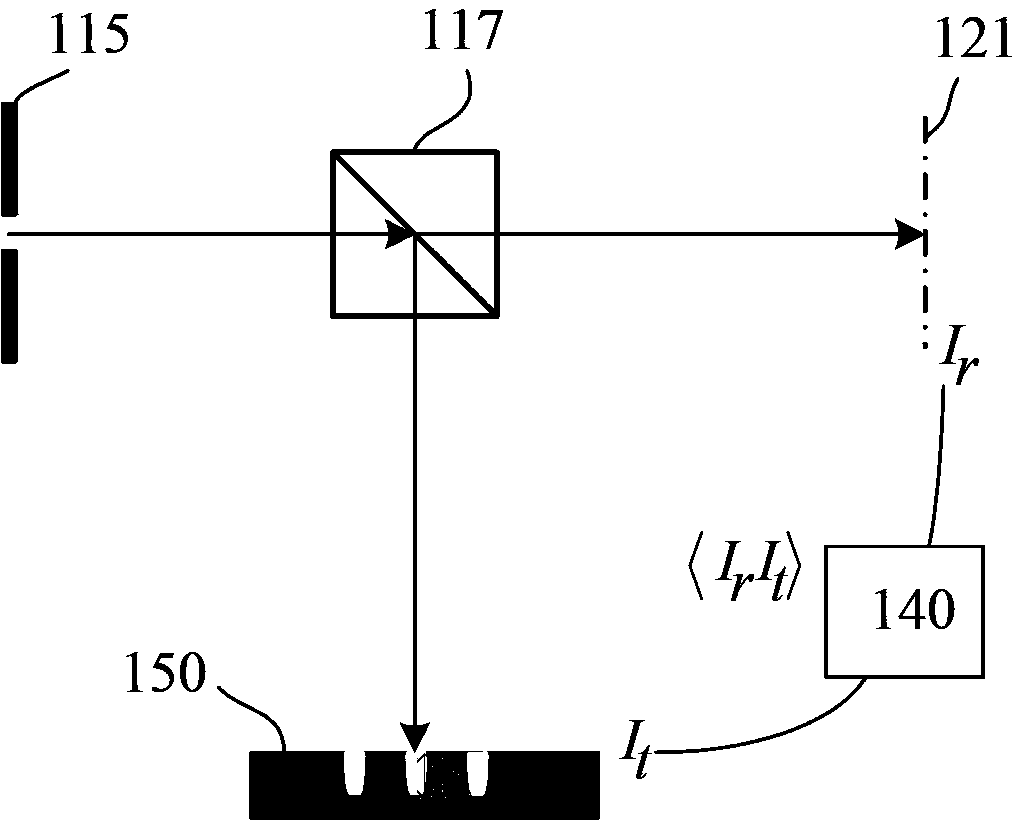

[0111] The lighting projection module of this embodiment is the same as that of Embodiment 2, and the common difference between Embodiment 1 and Embodiment 2 is that the reference imaging module in this embodiment is a virtual module, therefore, there is no need to use a separate imaging module in this embodiment. Beamer, control processing module and embodiment 1 and 2 are also different.

[0112] Please refer to Figure 9 , in this embodiment, the illumination projection module also includes an illumination light source 310, an optical modulation assembly 320, a variable diaphragm 330, and a reflector 340 arranged in sequence along the light propagation direction, wherein the structure of the illumination light source 310 is the same as that in Embodiment 2, Both adopt a plurality of lasers 311 with different wavelengths as the light source of the three-dimensional pattern detection device, and the optical modulation component 320 includes a beam expander 321, a spatial ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com