3D printing percutaneous vertebral pedicle guide plate, preparation method of 3D printing percutaneous vertebral pedicle guide plate, and using method of 3D printing percutaneous vertebral pedicle guide plate

A 3D printing and pedicle technology, applied in the medical field, can solve the problem of rare mobile CT in the operating room, and achieve the effects of shortening the operation time, accurate screw placement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

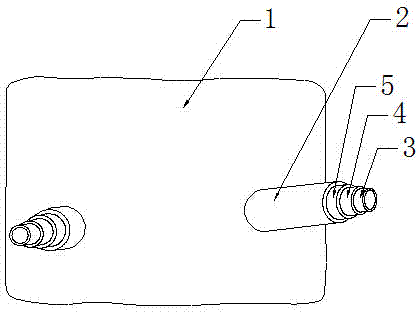

[0035] The preparation method of the 3D printed percutaneous pedicle guide plate of the present invention includes the steps of establishing a three-dimensional geometric model, determining the pedicle screw path, generating the guide plate, 3D printing and installing the sleeve, which are specifically:

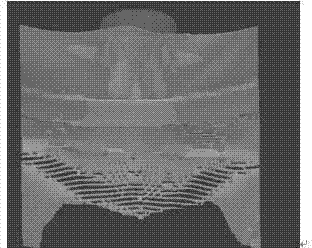

[0036] (1) The establishment of three-dimensional geometric model: Obtain the patient's imaging data from the workstation and import it into the medical modeling software in DICOM format. Through morphological processing, a visual bone model and skin model are generated, such as figure 2 with 3 As shown, and export and save in stl format respectively;

[0037] (2) Determination of the pedicle screw path: In the medical modeling software, extract the pedicle shape and fit into a cylindrical channel, which is the best screw path. Measure the length of the screw path in the software, and then The road is reversed and extended through the skin to form a body surface mark, and then exp...

specific example

[0049] A patient, male, 57 years old. He was admitted to the hospital for "repeated waist and hip pain for half a year". The physical examination showed that the lumbar spine had physiological arc, lumbar 4 and 5 spinous processes, interspinous tenderness, mild percussive pain, both lower limbs straight leg elevation test 70° negative, double Muscle strength and sensation of lower limbs are normal. Examination of the front and lateral view of the lumbar spine showed that the lumbar 4 vertebral body had second degree spondylolisthesis, and the lumbar spine CT showed that the lumbar 4th vertebral body had second degree spondylolisthesis, the intervertebral disc herniation was not obvious, and the pedicle was intact. The admission diagnosis was: "Lumbar 4 spondylolisthesis". Percutaneous pedicle screw internal fixation under general anesthesia was performed, and 3D printed percutaneous pedicle guide plates were used during the operation. Specific steps are as follows:

[0050] 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com